Insulation structure and high-voltage direct-current cable

A technology of insulation structure and insulation layer, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of the decline of the electrical insulation performance of high-voltage DC cables, affecting the safety and stable operation of cables, and the uneven insulation performance of the insulation layer. Weaken the effect of internal electric field reversal, uniform residual quantity, and uniform insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment discloses an insulating structure, which can be used as an insulating layer in a high-voltage direct current cable, which includes a multi-layer annular structure, and each layer of the annular structure includes a matrix, and the matrix is processed by a mixture of a base material and a cross-linking agent and the content of the crosslinking agent in the mixture used in the matrix of each layer of annular structure gradually increases from the inner layer to the outer layer.

[0036] Specifically, polyethylene is preferably used as the base material in the mixed material used in the matrix of each layer of annular structure, so as to maintain the consistency of the matrix material of each layer of annular structure, which can be used as a high-voltage direct current cable and other equipment. When the insulating layer is used, the interlayer problem caused by the interface of the insulating layer can be effectively avoided. As a crosslinking agent, DC...

Embodiment 2

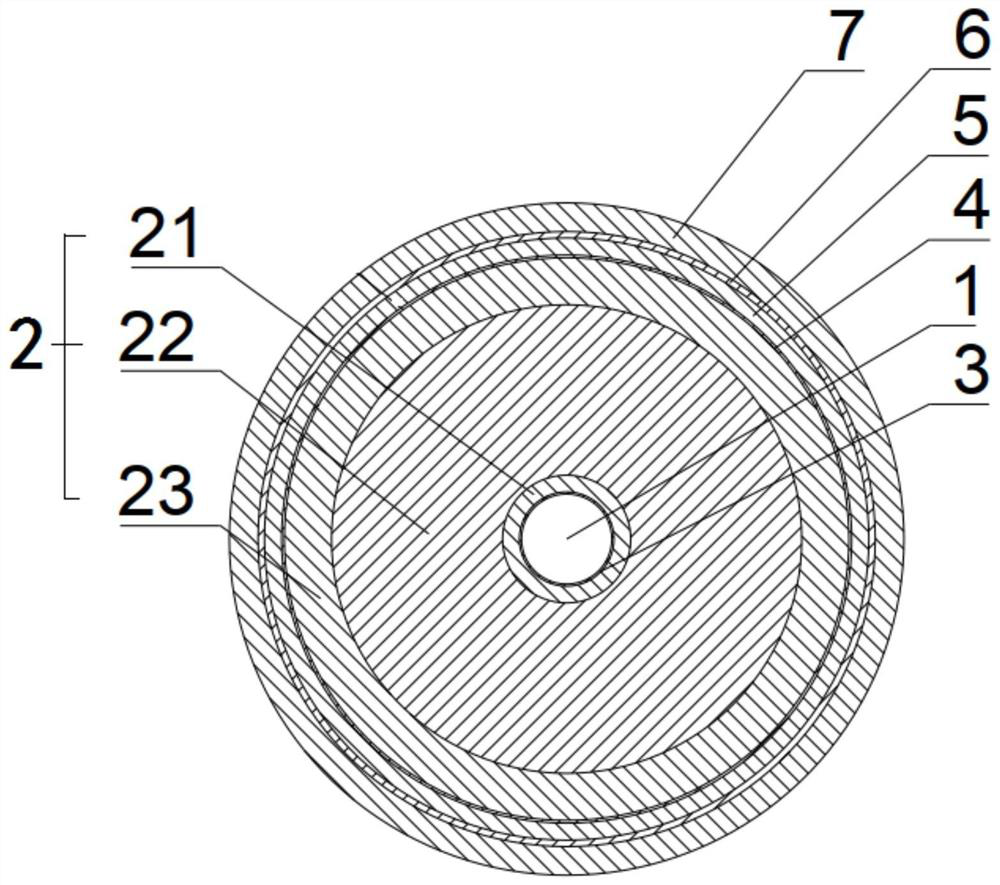

[0058] This embodiment discloses a high-voltage DC cable, which includes a conductor 1 and a protective layer, the protective layer includes an insulating layer 2, the insulating layer 2 is provided outside the conductor 1, and the insulating layer 2 adopts the insulating structure described in Embodiment 1.

[0059] Specifically, as figure 1 As shown, the insulating layer 2 of the high-voltage DC cable in this embodiment preferably includes a three-layer annular structure, which are sequentially an inner insulating layer 21, a middle insulating layer 22, and an outer insulating layer 23 from inside to outside, and the inner insulating layer 21 wraps Outside the conductor 1, the inner insulating layer 21, the middle insulating layer 22, and the outer insulating layer 21, the middle insulating layer 22, and the outer insulating layer are made by using different contents of cross-linking agents in the inner insulating layer 21, the middle insulating layer 22, and the outer insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com