Method and device for making potato balls

A production device and production method technology, applied in chemical instruments and methods, food forming, food coating and other directions, can solve the problems of reducing the production efficiency of potato balls, high labor intensity, easy to accumulate in mesh holes, etc. The effect of improving production efficiency, reducing labor intensity and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

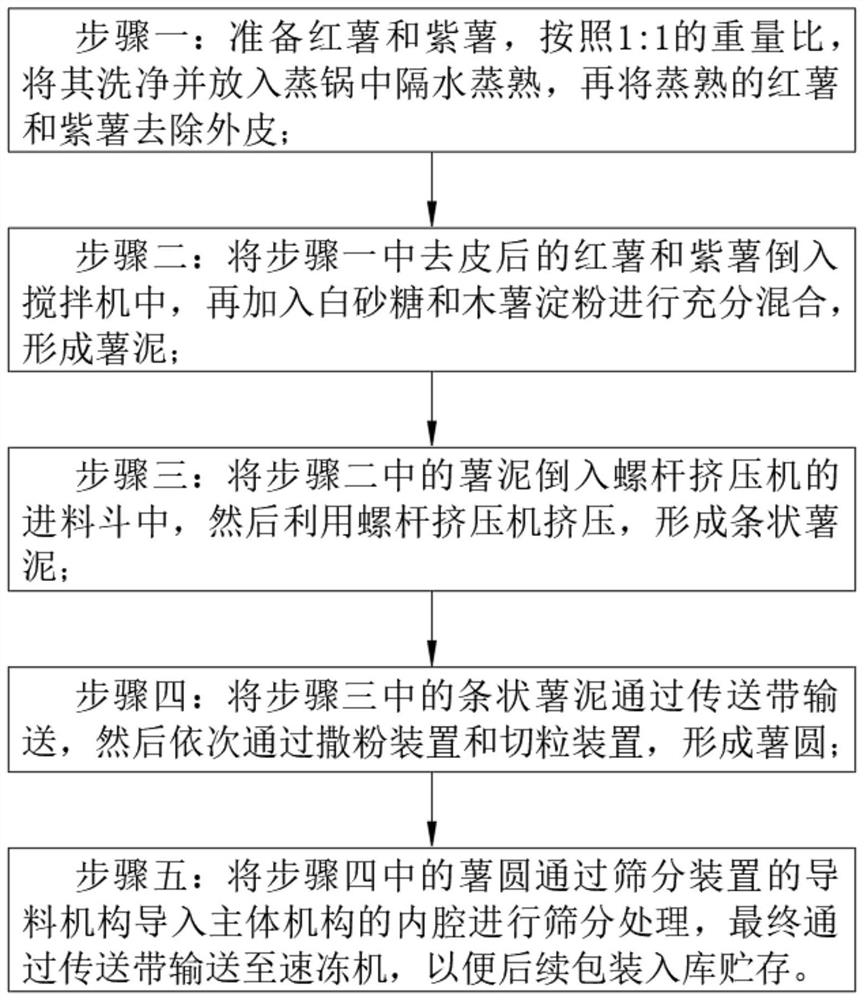

[0045] like figure 1 As shown, the present implementation proposes a method for making potato balls, comprising the following steps:

[0046] Step 1: Prepare sweet potatoes and purple potatoes, wash them according to the weight ratio of 1:1, put them in a steamer and steam them with water, and then remove the outer skin of the steamed sweet potatoes and purple potatoes;

[0047] Step 2: Pour the peeled sweet potatoes and purple potatoes in the first step into a blender, then add white sugar and tapioca starch to fully mix to form mashed potatoes;

[0048] Step 3: Pour the mashed potato in step 2 into the feed hopper of the screw extruder, and then extrude with the screw extruder to form strip-shaped mashed potato;

[0049] Step 4: The strip-shaped mashed potato in Step 3 is conveyed through the conveyor belt, and then passed through the powdering device and the dicing device in turn to form potato balls;

[0050] Step 5: The potato balls in Step 4 are introduced into the inn...

Embodiment 2

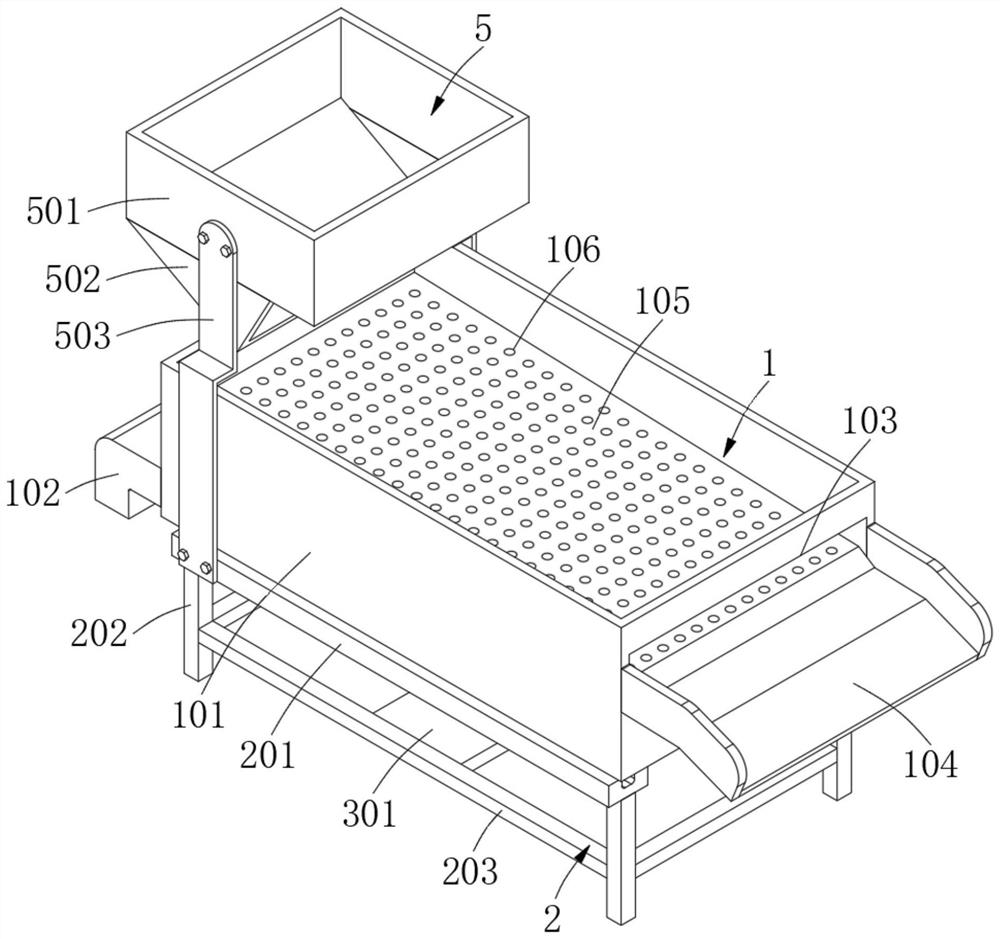

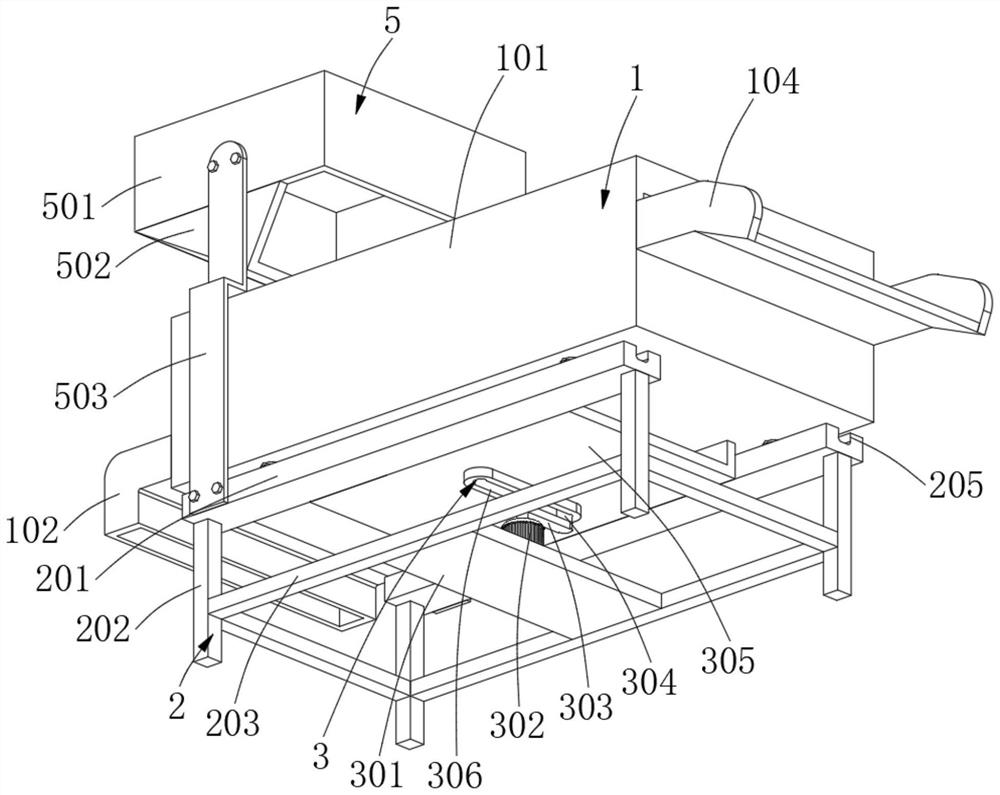

[0053] like Figure 2-10 As shown, this embodiment provides a device for making potato balls, including the above-mentioned screening device, and the screening device includes a main body mechanism 1, a support mechanism 2, a drive mechanism 3, a connection assembly 4 and a material guide mechanism 5;

[0054] Wherein, the main body 1 is used to screen the diced potato balls, and the main body 1 includes a screening box 101, the lower part of one side of the screening box 101 is connected with a discharge pipe 102, and the other side of the screening box 101 is connected. The upper part of the side is provided with a discharge hole 103, the surface of the screening box 101 is fixedly connected with a first material guide plate 104, the inner cavity of the screening box 101 is provided with a screening plate 105, and one side of the screening plate 105 penetrates to the discharge port. In the inner cavity of the material hole 103, the surface of the sieving plate 105 is provide...

Embodiment 3

[0069] like Figure 11 As shown, a method for making potato balls includes the following steps:

[0070] 1) Peel the fresh sweet potatoes and wash them with a washing machine;

[0071] 2) Put the washed sweet potatoes into the steamer and steam until fully cooked;

[0072] 3) Put the steamed sweet potato together with tapioca starch, white granulated sugar and water into the mixing hopper and stir, until it becomes mashed, thereby obtaining mashed sweet potato;

[0073] 4) The mashed sweet potato is pressed and extruded by a screw extruder, so that the mashed sweet potato is formed into slender mashed sweet potato strips, and at the same time, the mashed sweet potato strips are evenly sprinkled with tapioca starch, and then the mashed sweet potato strips are diced into round shapes, Thereby obtaining sweet potato circles;

[0074] 5) Pack and freeze the sweet potato rounds according to the specifications.

[0075] In order to facilitate the understanding of the above techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com