Quickly-discharging berry liquid extraction device and extraction method

An extraction device and extraction method technology, applied in separation methods, chemical instruments and methods, solid solvent extraction, etc., can solve the problems of easy clogging of circulation extraction pipelines, large equipment investment, and long extraction time, etc., to prevent easy clogging, The effect of strengthening the filtration speed and improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

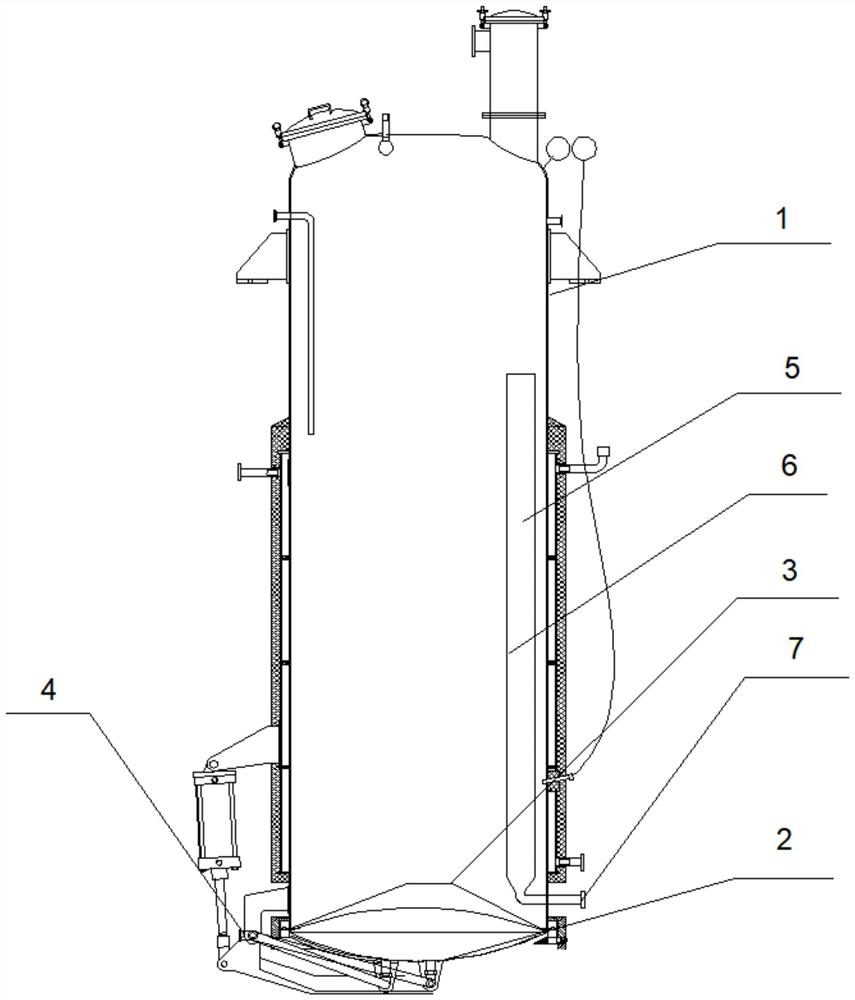

[0039] refer to figure 1 , the present embodiment shows a fast discharging berry liquid extraction device, including a tank body 1, an openable lower head 2, a filter screen 3, a liquid outlet pipe 14 and a liquid outlet device 5, wherein:

[0040] The filter screen 3 is arranged above the lower head 2 and fixed on the inner wall of the tank body 1, and the liquid outlet pipe I4 is located on the lower side of the filter screen 3;

[0041] The liquid outlet device 5 includes a rotatable filter cartridge 6 and a liquid outlet pipe II7 located at the lower end of the filter cartridge 6. The filter cartridge 6 is vertically installed in the tank body 1 and has a gap with the tank body 1, so that it is in the tank body. 1 The outer scraping surface and the inner filter surface are formed inside, refer to Figures 3 to 9 , the cross section of the filter cartridge 6 can be any one of circle, ellipse, triangle, square, inline, polygonal star or other suitable shapes;

[0042] The ...

Embodiment 2

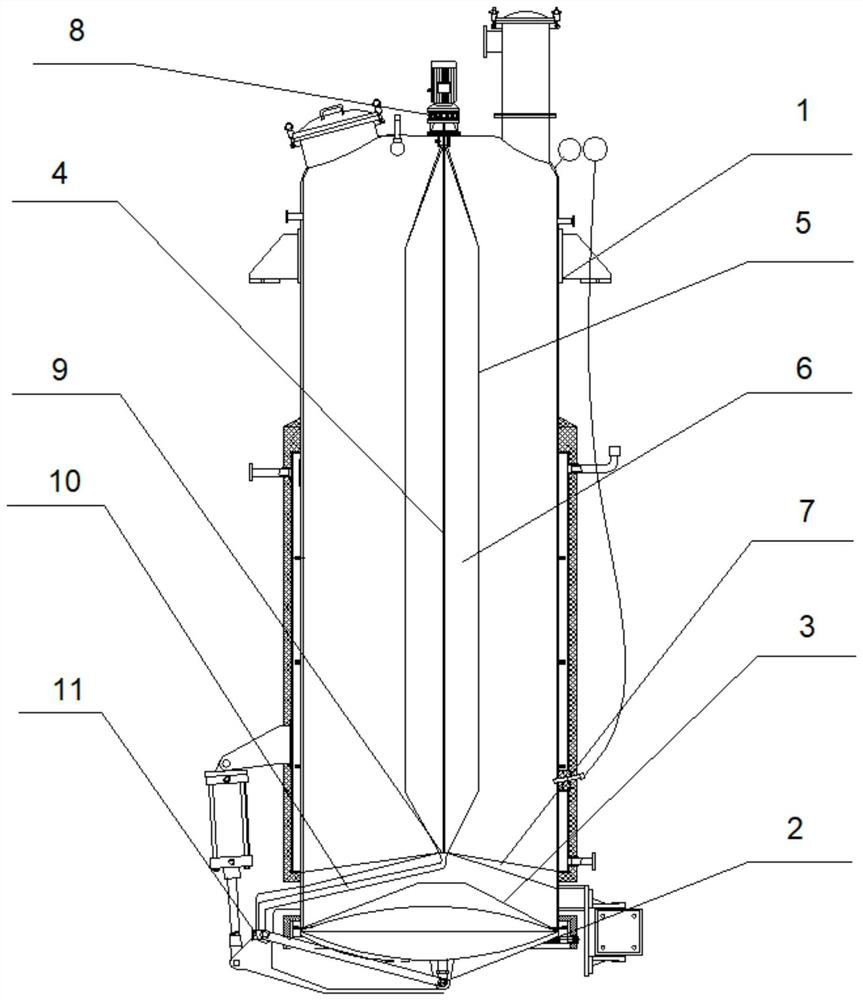

[0044] refer to figure 2 , the present embodiment shows a fast discharging berry liquid extraction device, including a tank body 1, an openable lower head 2, a filter screen 3, a liquid outlet pipe 14 and a liquid outlet device 5, wherein:

[0045] The filter screen 3 is arranged above the lower head 2 and fixed on the inner wall of the tank body 1, the filter screen 3 is in the shape of a frustum, and the liquid outlet pipe I4 is located on the lower side of the filter screen 3;

[0046] The liquid outlet device 5 includes a filter cartridge 6, a liquid outlet pipe II7, a motor 8, a rotating shaft 9, and a support assembly. The filter cartridge 6 is fixed on the rotating shaft 9 and is vertically installed at the center position of the tank body 1, and is between the inner wall of the tank body 1. Leave a gap so that it forms a scraping surface and a filtering surface in the tank 1, refer to Figures 3 to 9 , the cross section of the filter cartridge 6 is any one of a circl...

Embodiment 3

[0050] The present embodiment provides a rapid-discharge berry liquid extraction method, which is applied to the rapid-discharge berry liquid extraction device described in any of the above embodiments, and the method includes the following steps

[0051] S1, thermally leaching the berries;

[0052] S2, after the leaching is completed, start the liquid outlet device 5 to make the filter cartridge 6 rotate, and then open the liquid outlet pipe II7 connected to the filter cartridge 6. When the liquid outlet pipe II7 no longer flows out the feed liquid, open the outlet connected to the filter screen 3 again. For the liquid pipe I4, the discharging operation is completed after the liquid discharge pipe I4 no longer flows out the material liquid.

[0053] Wherein, the mode of starting the liquid outlet device 5 to make the filter cartridge 6 rotate includes:

[0054] Active and passive;

[0055] Especially the active type quick discharge extraction kettle, after the motor 8 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com