Particulate matter unloading device special for railway hopper car

A technology of unloading device and hopper car, which is applied to the loading and unloading of railway vehicles, hopper cars, railway car body parts, etc., which can solve the problems of high transportation loss, multiple overturning, and small load, so as to reduce labor intensity and improve unloading The effect of improving speed and unloading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the specific embodiments, which further illustrate the principles of the present invention and do not limit the present invention in any way, and the same or similar technologies as the present invention do not exceed the protection scope of the present invention.

[0029] In conjunction with the attached drawings.

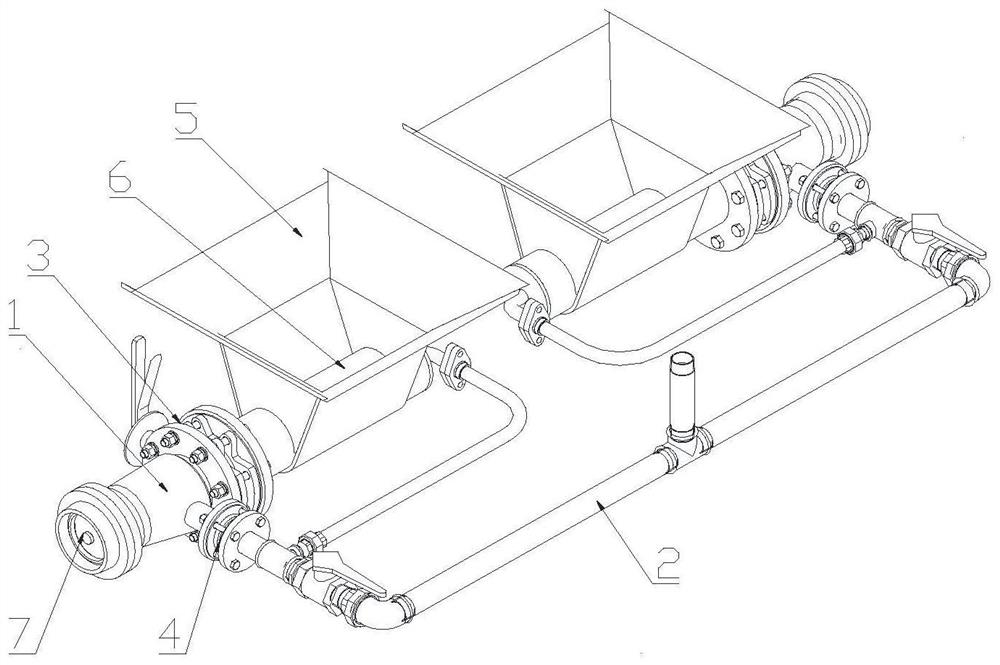

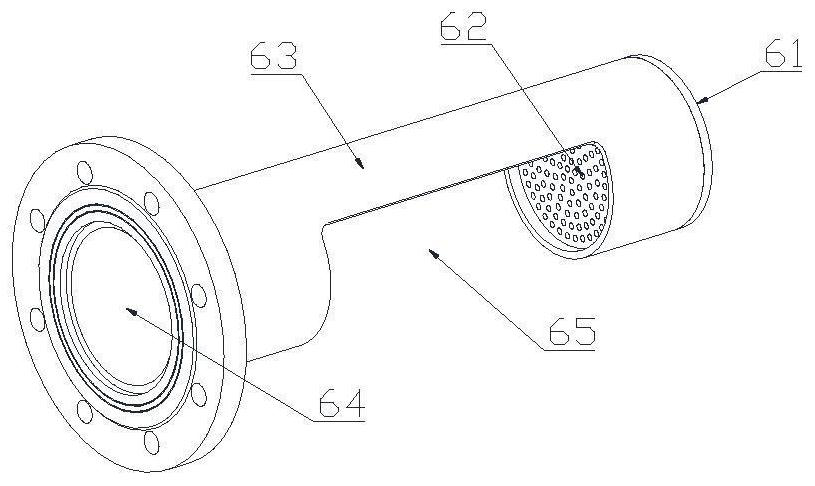

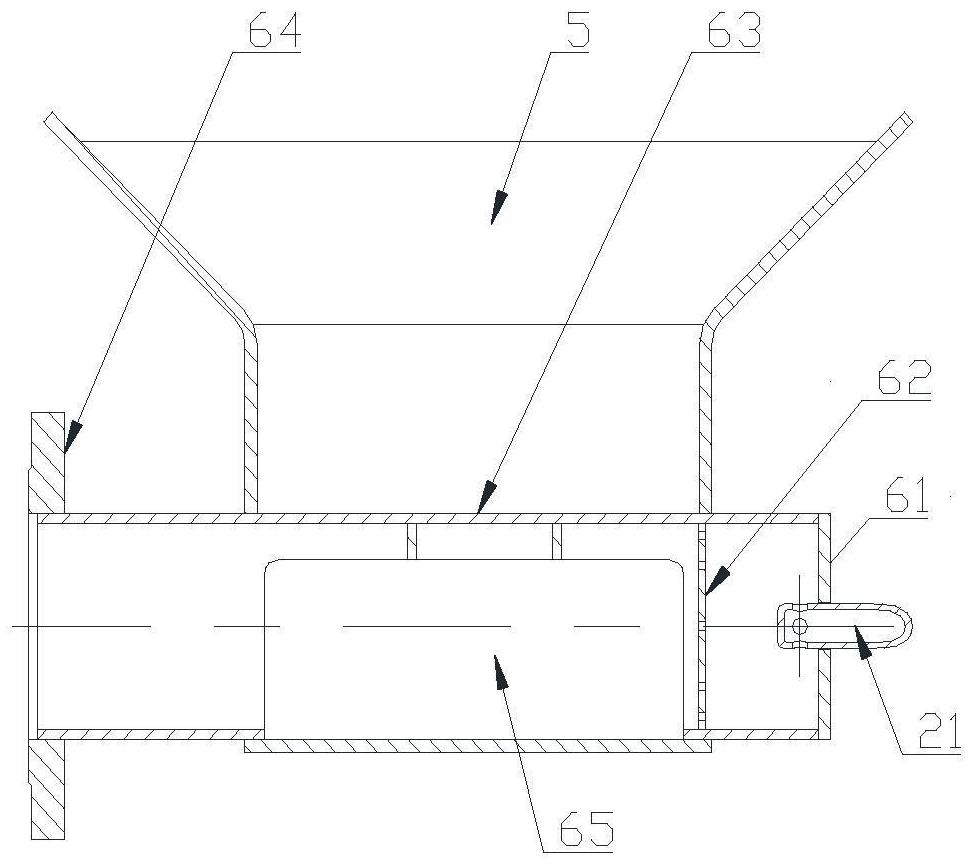

[0030] The particulate matter unloading device of the special railway hopper car of the present invention utilizes the mixed action of gravity and air pressure to realize the unloading of particulate matter. The unloading device includes two sets of unloading mechanisms, each set of unloading mechanism is composed of unloading funnel 5, unloading mixer 6, butterfly valve 3, quick joint 7, annular pressurizer 1, dust cover, one-way valve 4, cut-off plug door, etc. Each set of unloading mechanism is provided with high-pressure gas by a parallel air supply system 2; wherein, the unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com