Method for improving triboelectricity output performance by inductively coupled plasma dry etching

A dry etching, inductive coupling technology, used in triboelectric generators, nanotechnology for materials and surface science, nanostructure manufacturing, etc. Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

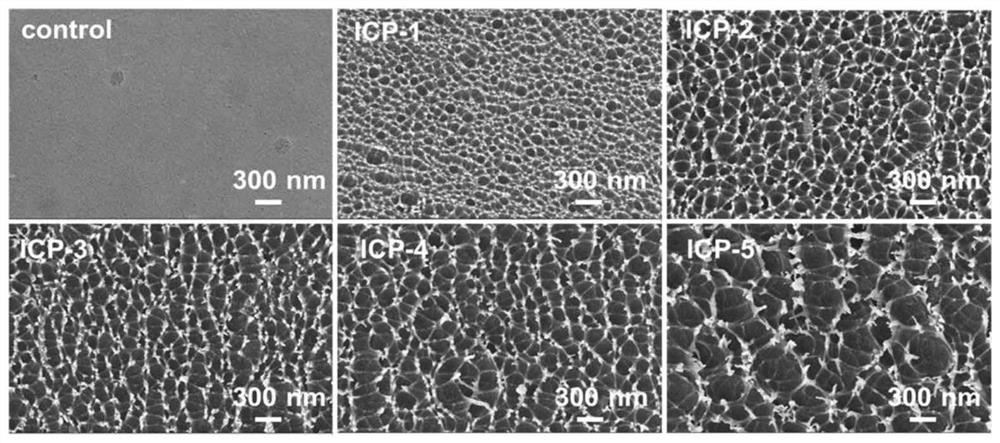

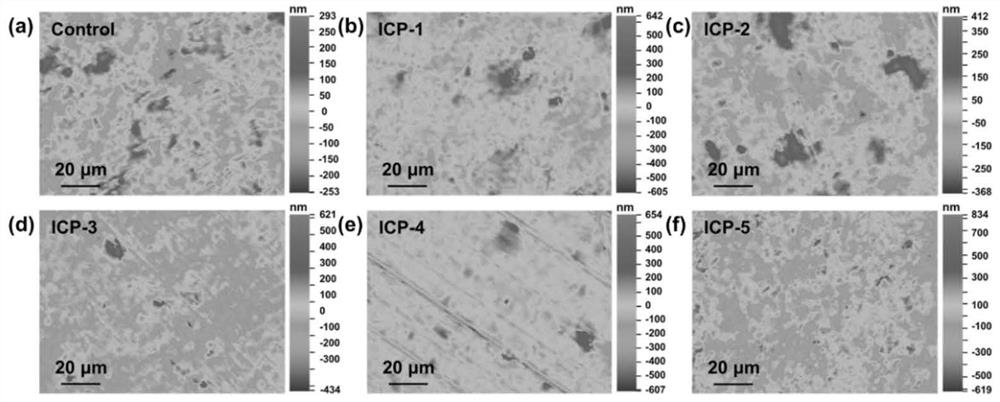

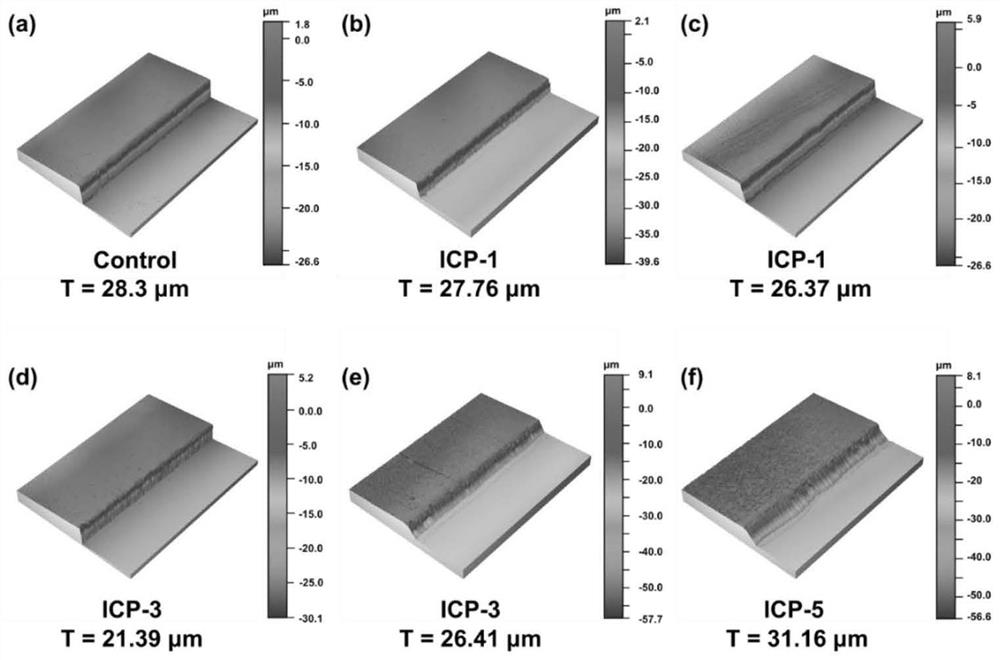

[0055] The method for improving the triboelectric output performance of a polyvinyl chloride (PVC) film based on an inductively coupled plasma dry etching technology includes the following steps:

[0056] Step S1: cleaning of the PVC film: take a PVC film cut into 4*4cm and place it in anhydrous ethanol for ultrasonic cleaning for 10 minutes, then ultrasonically clean it with deionized water for 10 minutes, and then dry to obtain a clean PVC film;

[0057] Step S2: placing the cleaned PVC film in the carrier for plasma etching, and sending it into the cavity of the plasma dry etching equipment;

[0058]Step S3: the equipment is evacuated to keep the pressure stable, and the etching process is divided into two stages. The first stage: pass 15sccm O2, 45sccm CHF 3 , the ICP power is 100W, the RF power is 10W, and the etching time is 10min; the second stage: pass 50sccm C4F8, the ICP power is set to 100W, the RF power is 10W, and the etching time is 10s;

[0059] Step S4: after...

Embodiment 2

[0062] The steps of Example 2 are the same as those of Example 1, except that:

[0063] In step S3, the RF power is 20W;

[0064] In step S5, the etched PVC film ICP-2 is taken out;

Embodiment 3

[0066] The steps of Example 2 are the same as those of Example 1, except that:

[0067] In step S3, the RF power is 25W;

[0068] In step S5, the etched PVC film ICP-3 is taken out;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com