High-strength glass fiber reinforced plastic and preparation method thereof

A glass fiber reinforced plastic, high-strength technology, applied in the field of fiber-reinforced plastics, can solve the problems of low strength and narrow use range of pressed reinforced plates, and achieve the effects of improving waste utilization, tensile strength, and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

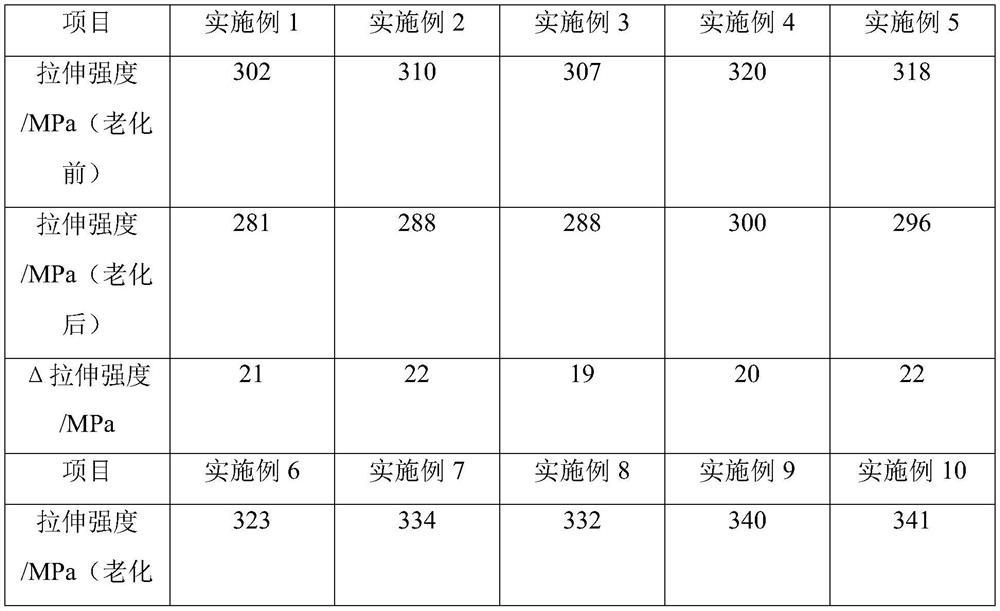

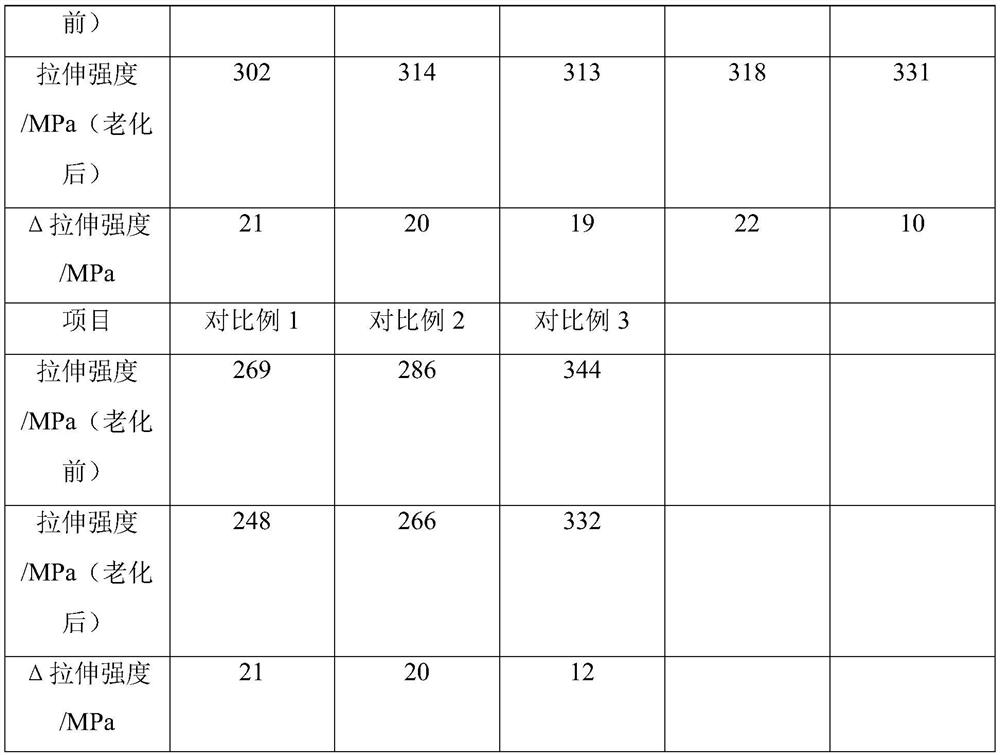

Examples

Embodiment 1

[0051] A high-strength glass fiber reinforced plastic, the preparation method of which comprises the following steps:

[0052] S1, 75kg isophthalic unsaturated polyester, 25kg vinyl resin, 60kg polyester glass fiber reinforced plastic waste, 10.2kg ethylene-butene copolymer are heated to molten state while stirring, to obtain A material;

[0053] S2. Add 22kg glass fiber, 1kg silane coupling agent KH550, 0.8kg antioxidant 1024, 8kg ultraviolet absorber UVP-327, 2kg benzoyl peroxide, 1kg N,N-dimethylaniline to material A, and add 600r The stirring speed of / min stirs and reacts for 60 minutes, pours, and obtains FRP after curing.

Embodiment 2

[0055] A high-strength glass fiber reinforced plastic, the preparation method of which comprises the following steps:

[0056] S1, 80kg isophthalic unsaturated polyester, 20kg vinyl resin, 60kg polyester glass fiber reinforced plastic waste, 12.5kg ethylene-butene copolymer are heated to molten state while stirring, to obtain A material;

[0057] S2, add 28kg glass fiber, 2kg silane coupling agent KH550, 1.2kg antioxidant 1024, 6kg ultraviolet absorber UVP-327, 3kg benzoyl peroxide, and 0.5kg N,N-dimethylaniline to material A, with The stirring speed of 700r / min was stirred and reacted for 45min, poured, and the glass fiber reinforced plastic was obtained after curing.

Embodiment 3

[0059] A high-strength glass fiber reinforced plastic, the preparation method of which comprises the following steps:

[0060] S1, 80kg isophthalic unsaturated polyester, 20kg vinyl resin, 60kg polyester glass fiber reinforced plastic waste, 15.8kg ethylene-butene copolymer are heated to molten state while stirring, to obtain A material;

[0061]S2, add 35kg glass fiber, 3kg silane coupling agent KH550, 1.6kg antioxidant 1024, 4kg ultraviolet absorber UVP-327, 4kg benzoyl peroxide, 0.2kg N,N-dimethylaniline into A material, with The stirring speed of 800 r / min was stirred for 30 minutes, poured, and the glass fiber reinforced plastic was obtained after curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com