Method for combined production of TDI and stabilized tar and utilization method of stabilized tar

A stabilizing and tar technology, applied in chemical instruments and methods, tar refining by chemical methods, and preparation of organic compounds, etc., can solve the problems of complex treatment process, large molecular weight, poor stability, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

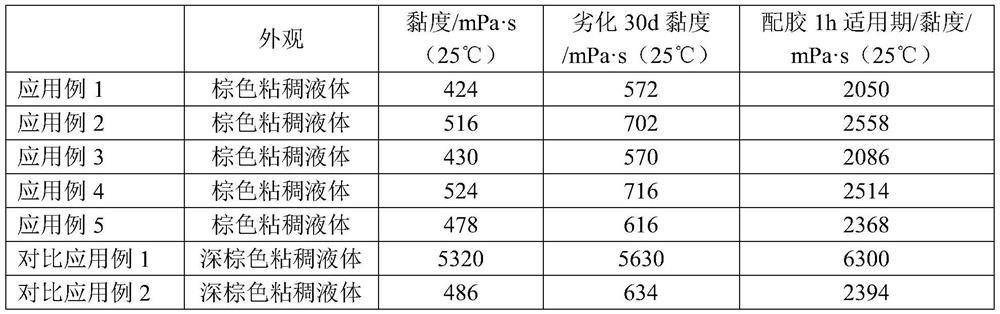

Examples

Embodiment 1

[0046] [Preparation Example 1] Preparation of Cyclopolyamine A

[0047] Aniline, formaldehyde, and hydrochloric acid were mixed at a molar ratio of 2:1:1, stirred at 50°C for 0.8h, and then stirred at 120°C for 2.2h. After the reaction was completed, 32% NaOH solution was added for neutralization, so that the remaining NaOH concentration in the solution after neutralization was 2%. Stand to separate and separate, take the upper oil phase, remove aniline and water by steam stripping, and obtain the cyclic polyamine product, which is recorded as cyclic polyamine A.

[0048] Cyclic polyamine A was analyzed by liquid chromatography, and the number of single-molecule aromatic rings was 2.

Embodiment 2

[0049] [Preparation Example 2] Preparation of Cyclopolyamine B

[0050] Aniline, formaldehyde, and 50% sulfuric acid were mixed at a molar ratio of 6:5:1, stirred at 40° C. for 1 h, and then stirred at 180° C. for 0.6 h. After the reaction was completed, 32% NaOH solution was added for neutralization, so that the remaining NaOH concentration in the solution after neutralization was 4%. Stand to separate and separate, take the upper oil phase, remove aniline and water by steam stripping, and obtain the cyclic polyamine product, which is recorded as cyclic polyamine B.

[0051] Cyclic polyamine A was analyzed by liquid chromatography, and the number of aromatic rings in the single molecule was 6.

Embodiment 3

[0052] [Preparation Example 3] Preparation of Cyclopolyamine C

[0053] Aniline, formaldehyde, and 50% sulfuric acid were mixed at a molar ratio of 4:3:0.5, stirred at 75°C for 0.5h, and then stirred at 160°C for 0.8h. After the reaction was completed, 32% NaOH solution was added for neutralization, so that the remaining NaOH concentration in the solution after neutralization was 1%. Stand to separate and separate, take the upper oil phase, remove aniline and water by steam stripping, and obtain the cyclic polyamine product, which is recorded as cyclic polyamine C.

[0054] Cyclic polyamine A was analyzed by liquid chromatography, and the number of aromatic rings in the single molecule was 4.

[0055] 【Example 1】

[0056] Mix toluenediamine, o-dichlorobenzene (ODCB), and cyclopolyamine A at a mass ratio of 1:2:0.2, and the mixing temperature is 100°C. The above mixed material was jet-mixed with a phosgene solution with a mass concentration of 50%, wherein the mass of phosge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com