Heating furnace heat storage box repairing material and preparation method thereof

A technology for repairing materials and heating furnaces, applied in the production of clay products, other household appliances, ceramic materials, etc., can solve problems such as affecting production efficiency, burning external steel structures, and increasing the temperature in the heating furnace area, and improving thermal shock stability. Service life, good wear resistance and erosion resistance, the effect of increasing the overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The process steps of the preparation method of the repairing material for the heat storage box of the heating furnace are: (1) using a small crusher and a ball mill to crush and ball mill the regenerated heat storage body, silicon oxide, power plant porcelain bottle and bauxite respectively; The double-layer porous sieve with a hole diameter of 0.001-0.1mm screens the ball mills of the above four raw materials to remove impurities in the raw materials;

[0024] (2) Select metal aluminum powder with a particle size of 0.001-0.1 mm; process the zirconium-containing refractory fiber blanket into cotton-like zirconium-containing refractory fiber filaments; and obtain all aggregate raw material powders and auxiliary materials;

[0025] (3) Mix the powder of the above-mentioned aggregates and perform the first stirring for 5-10 minutes to mix the aggregates evenly to obtain mixed aggregates;

[0026] (4) Add resole phenolic resin into the mixed aggregate, carry out the second...

Embodiment 1-7

[0030] Embodiment 1-7: The heating furnace heat storage box repair material and its preparation method are as follows.

[0031] (1) See Table 1 for the component distribution ratio of the aggregate described in each embodiment; see Table 2 for the addition amount of the auxiliary materials and binders in the repair material.

[0032] Table 1: Component distribution ratio (wt%) of the aggregate

[0033]

[0034] Wherein, the particle size of the aggregate is 0.001-0.1 mm.

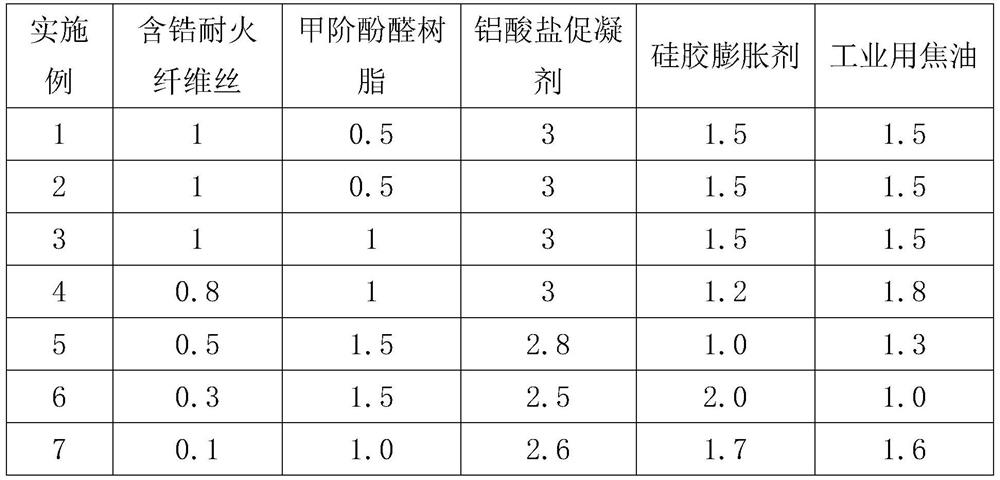

[0035] Table 2: The addition (wt %) of described auxiliary material and bonding agent in repair compound

[0036]

[0037] (2) Preparation is carried out according to the above process, and the specific process parameters of each embodiment are shown in Table 3.

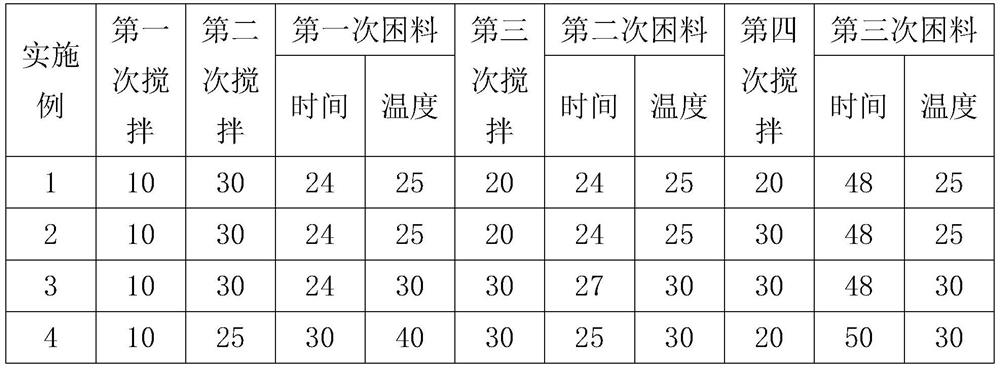

[0038] Table 3: the specific process parameters of each embodiment

[0039]

[0040]

[0041] In Table 3, the unit of stirring and trapping time is min, and the unit of trapping temperature is °C.

[0042] (3) The repair material ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com