Combined microalloying high-temperature-resistant aluminum alloy and preparation method thereof

A technology of micro-alloying and aluminum alloy, which is applied in the field of alloy materials and its preparation, can solve the problems of loss of strengthening effect and coarsening of strengthening phase, and achieve the effects of improving high-temperature mechanical properties, simple preparation process, and increasing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

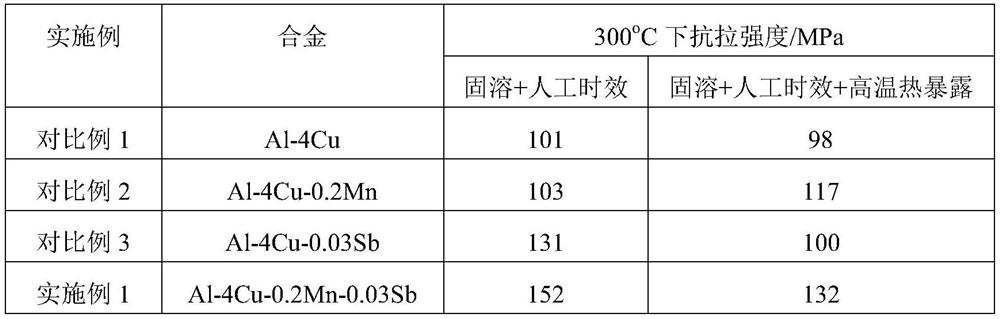

[0022] The invention provides a combined microalloyed high temperature-resistant aluminum alloy, which comprises the following components by mass percentage: Sb: 0.03wt.%, Mn: 0.2wt.%; the balance is Al-4wt.% Cu alloy.

[0023] The preparation method of the above-mentioned joint microalloyed high temperature-resistant aluminum alloy comprises the following steps:

[0024] (1) Obtain Al-20wt.%Cu aluminum alloy master alloy ingots, Sb-containing commercial master alloy ingots, and Mn-containing commercial master alloy ingots according to the mass percentage in the alloy components;

[0025] (2) The industrial pure aluminum and Al-20wt.%Cu aluminum alloy master alloy ingots were dried and placed in a graphite clay crucible, heated in a resistance furnace, heated to 700°C for melting, and then heated to 750°C for 1 hour. , Cool down to 720 ℃ and carry out refining treatment, after the temperature is stabilized at 710 ℃, put Al-10wt. When the molten aluminum temperature stabilizes...

Embodiment 2

[0029] On the basis of Example 1, the difference from Example 1 is that Sb: 0.01wt.%, Mn: 0.3wt.%; the balance is Al-4wt.%Cu alloy.

Embodiment 3

[0031] On the basis of Example 1, the difference from Example 1 is that Sb: 0.05wt.%, Mn: 0.1wt.%; the balance is Al-4wt.%Cu alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com