Nuclear power station steel lining variable cross-section special-shaped lining plate structure and manufacturing method thereof

A lining board and steel lining technology, which is applied in building construction, nuclear engineering, building components, etc., can solve the problems of long construction period, high safety risk, and existing steel bar obstacles, so as to reduce the amount of welding works, ensure manufacturing quality, The effect of increasing the format size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will now be described in further detail with reference to the accompanying drawings.

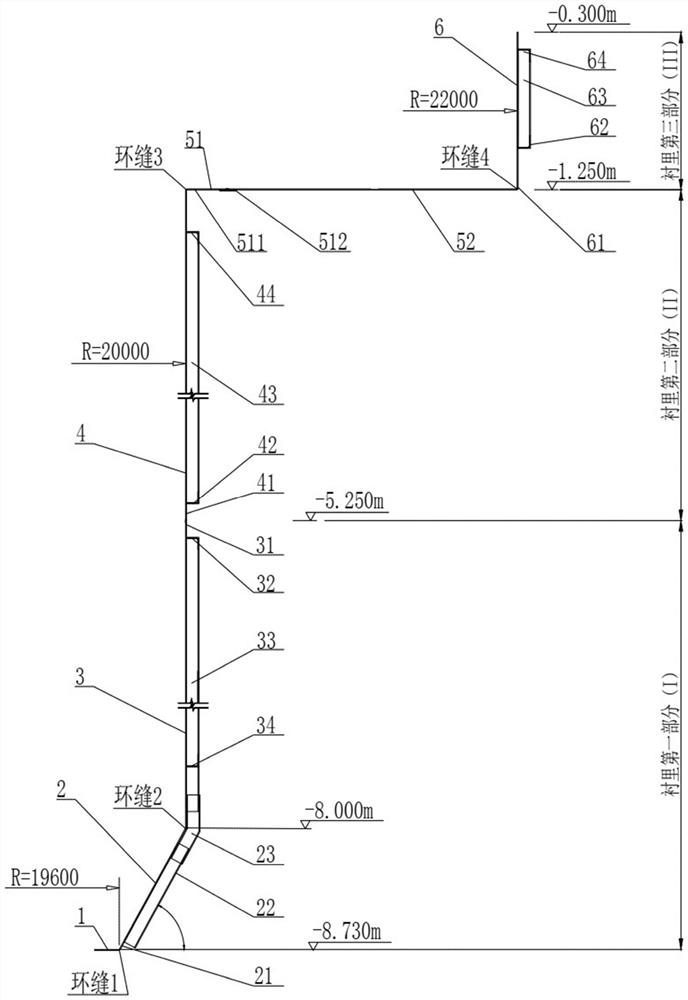

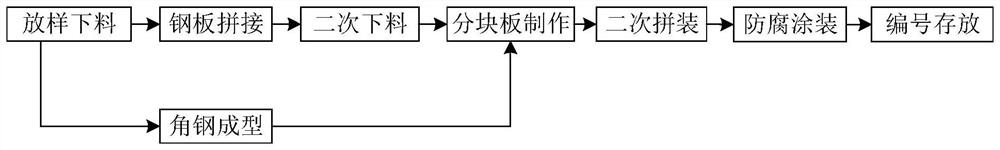

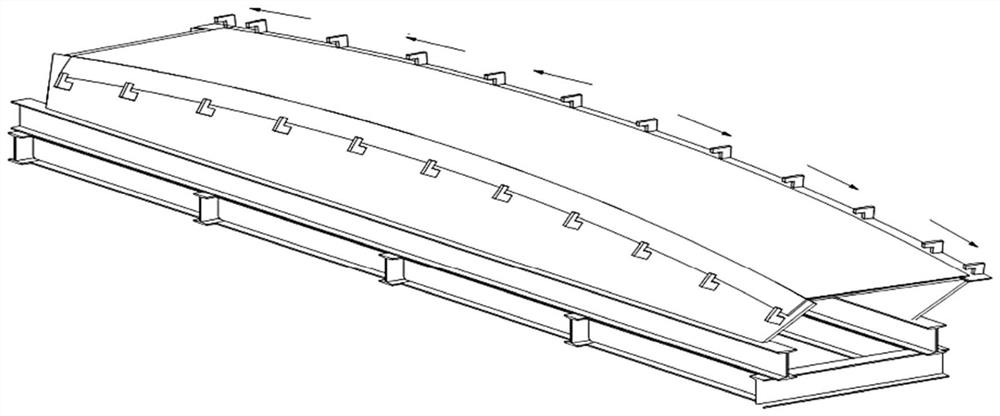

[0044] The steel lining variable section special-shaped lining plate structure of the present invention is as follows:figure 1 As shown, the corridor lining, the roof ring section 51, the corridor top plate 52 and the inner shell lining layer 6 composed of the floor ring section 1, the truncated cone 2, the first layer 3 of the corridor lining and the second layer 4 of the corridor lining, The floor ring section 1 and the gallery top plate 52 are both arranged horizontally, the frustum 2 and the floor ring section 1 are at an inclination angle of 61.3°, and the gallery linings 3 and 4 and the inner shell lining layer 6 are vertically arranged. According to the manufacturing process, the whole structure is divided into three parts: the lower end and the upper end of the frustum 2 are respectively connected with the floor ring segment 1 and the first layer of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com