Construction method for underground excavation tunnel advanced disintegration mechanical crushing

A technology of mechanical crushing and construction method, applied in tunnels, earthwork drilling, mining equipment and other directions, can solve the problems of restricting construction progress, large construction cost, waste of construction resources, etc., to save construction resources, improve construction efficiency, reduce construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

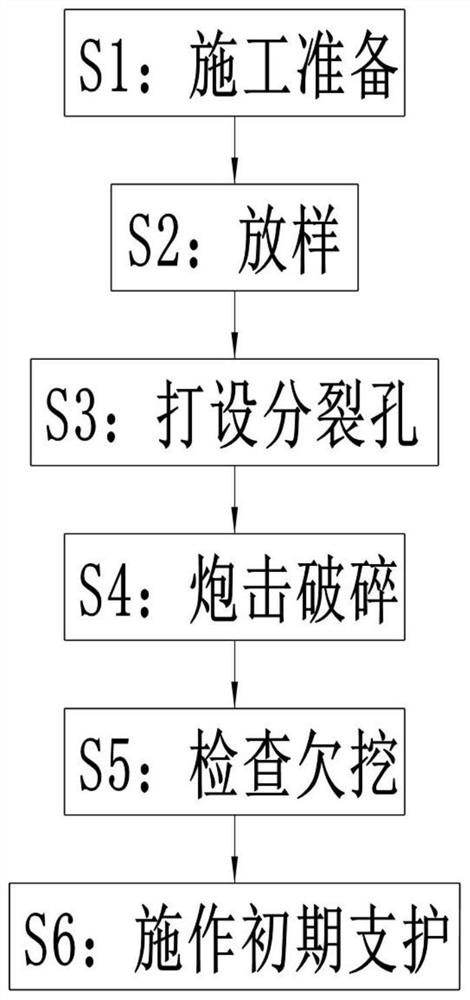

[0026] basically as attached figure 1 Shown: a construction method for advanced disintegration and mechanical crushing of an undercut tunnel, comprising the following steps:

[0027] S1: Construction preparation: prepare drilling machines, shelling, excavators and slag trucks, and connect to wind and hydropower;

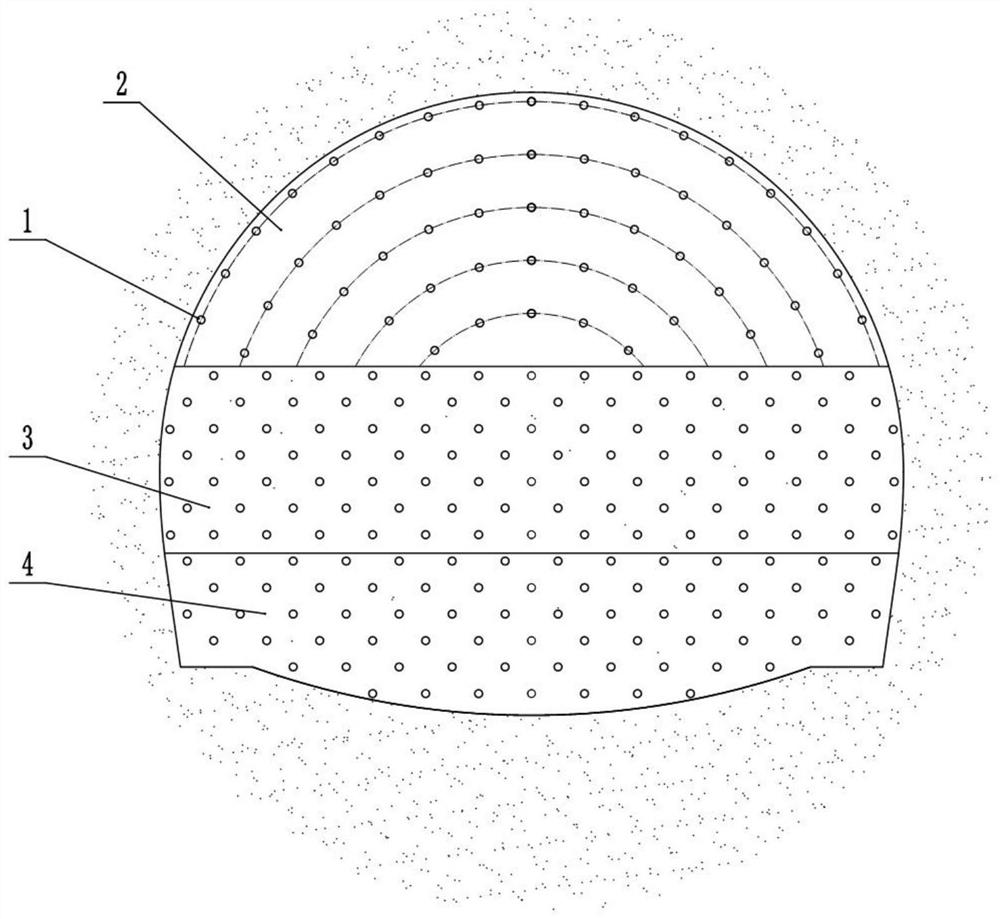

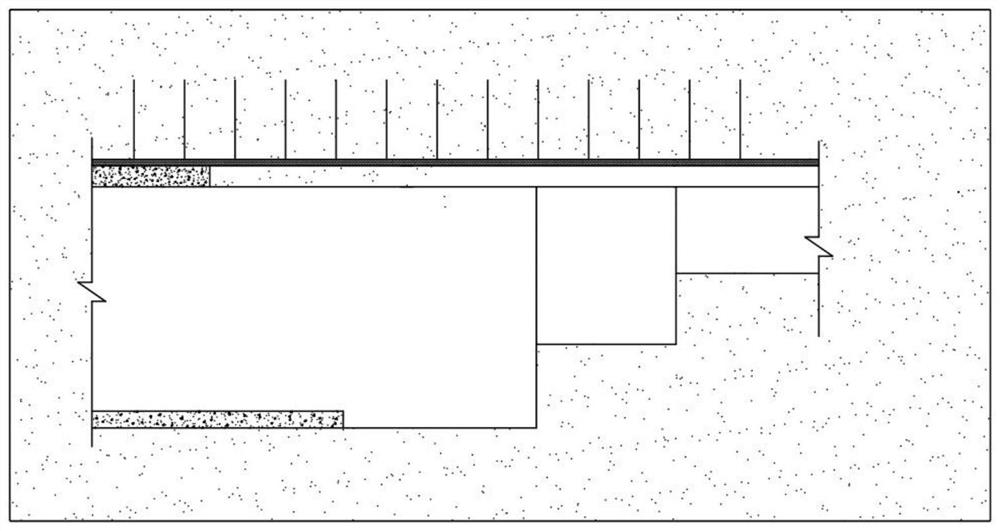

[0028] S2: Stakeout: According to the design size, the outline of the tunnel excavation and the location of the split hole 1 layout point are released. The tunnel excavation adopts stepped construction, combined with figure 2 , image 3 As shown, the part of the rock formation in the tunnel is divided into three steps: upper, middle and lower. During construction, the upper, middle and lower steps 4 are constructed in sequence, and the center line of the split hole 1 located in the outermost layer of the upper step 2 is away from the excavation contour line. 100mm, the split holes 1 of the upper step 2 are arranged in an annular manner, the adjacent annular layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com