Non-stop conveying belt pressure opening construction method and plugging pipe connecting device of non-stop conveying belt pressure opening construction method

A construction method and technology for plugging pipes, applied in valve devices, pipes/pipe joints/fittings, devices preventing accidental or unauthorized actions, etc., can solve problems such as difficult operation, and achieve good sealing effect and work. The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

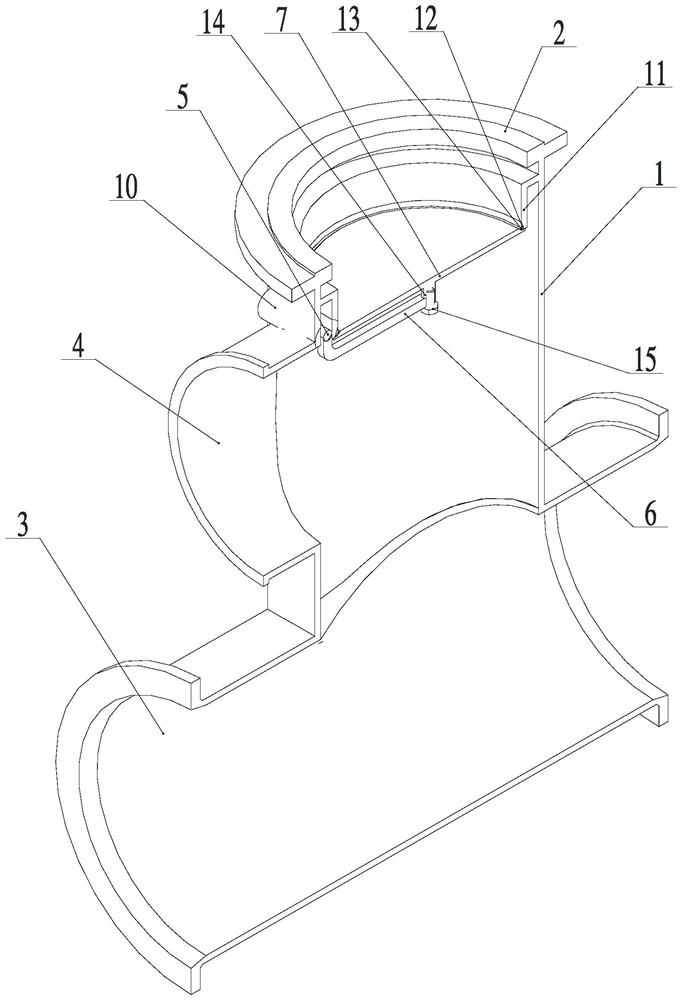

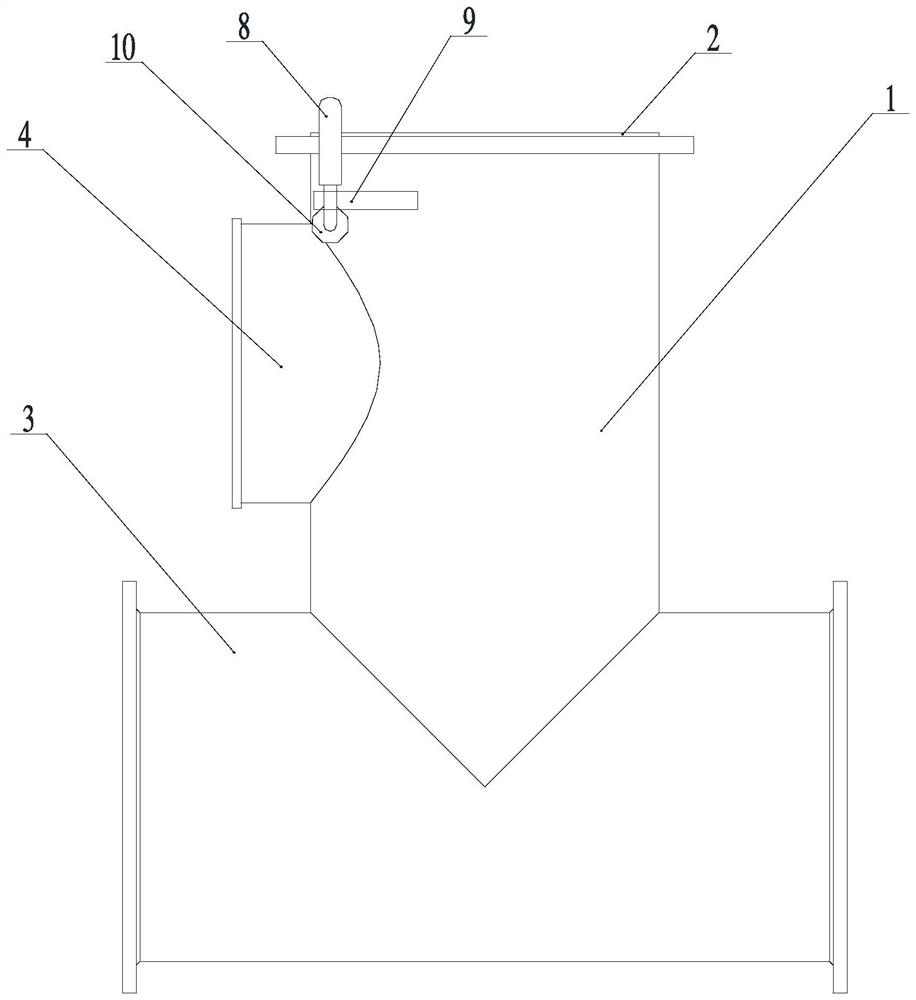

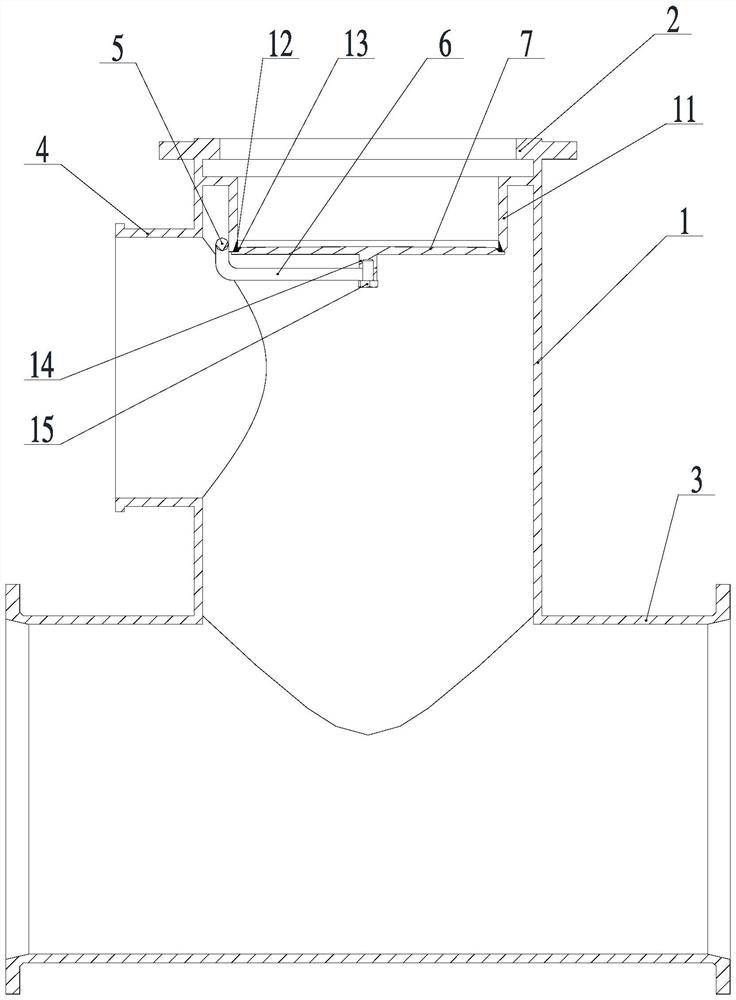

[0048] like figure 1 , 2 , 3, according to the design requirements, manufacture and process the plugging main pipe 1, the connecting flange of the drilling machine 2, the air source pipeline reinforcement 3, the branch pipe 4, the rotating shaft 5, the connecting rod 6, the flap 7, the manual operation handle 8 , Limit ring 9 , shaft hub 10 , blocking pipe 11 , blocking sealing belt 12 , flap sealing strip 13 , boss 14 .

[0049] like image 3 , 4 As shown, the connecting flange 2 of the drilling machine, the reinforcing part 3 of the gas source pipeline, and the branch pipe 4 are processed on the blocking main pipe 1, and the boss 14 is processed to the center position of the bottom of the flap 7.

[0050] like image 3 As shown, the blocking sealing tape 12 is coked and adhered to the lower circumference of the blocking pipe 11 , and the flap sealing strip 13 is pasted on the lower circumference of the flap 7 .

[0051] like image 3 As shown, the manual operating hand...

Embodiment 2

[0056] like Figure 5 As shown, according to the design requirements, make and process the plugging main pipe 1, the connecting flange of the drilling machine 2, the reinforcement part of the air source pipeline 3, the two branch pipes 4, the rotating shaft 5, the connecting rod 6, the flap 7, the manual operation handle 8 , Limit ring 9 , shaft hub 10 , blocking pipe 11 , blocking sealing belt 12 , flap sealing strip 13 , boss 14 .

[0057] like Figure 5 As shown, the connecting flange 2 of the drilling machine, the reinforcing part 3 of the gas source pipeline, and the two branch nozzles 4 are processed on the plugging main pipe 1, and the upper part of the plugging pipeline device is in the state of a three-way pipeline, and the boss 14 Processed to the center of the bottom of the flap 7.

[0058] like Figure 5 As shown, the blocking sealing tape 12 is coked and adhered to the lower circumference of the blocking pipe 11 , and the flap sealing strip 13 is pasted on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap