Pneumatic drying method and system for manganese dioxide

A technology of airflow drying and manganese dioxide, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of incomplete drying, difficulty, large transportation, etc., and achieve compact structure, convenient maintenance, continuous The effect of stable delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solution of the present invention is described in detail below. The following embodiments are implemented on the premise of the technical solution of the present invention, and a detailed implementation process is given. However, the protection scope of the present invention is not limited to the following embodiments. The following embodiments Structures or experimental methods for which specific conditions are not stated in the text are usually in accordance with conventional conditions.

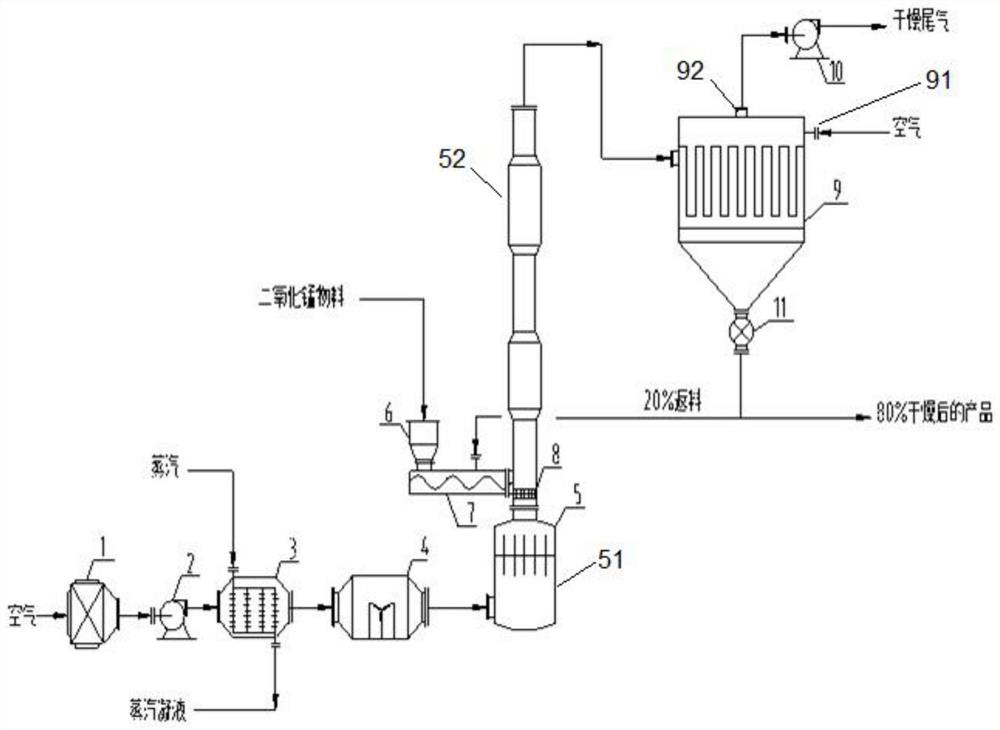

[0059] The invention discloses an air flow drying system for manganese dioxide, such as figure 1 As shown, it includes an airflow drying device 5, a feeding device 7, a heating device and a dust removal device 9.

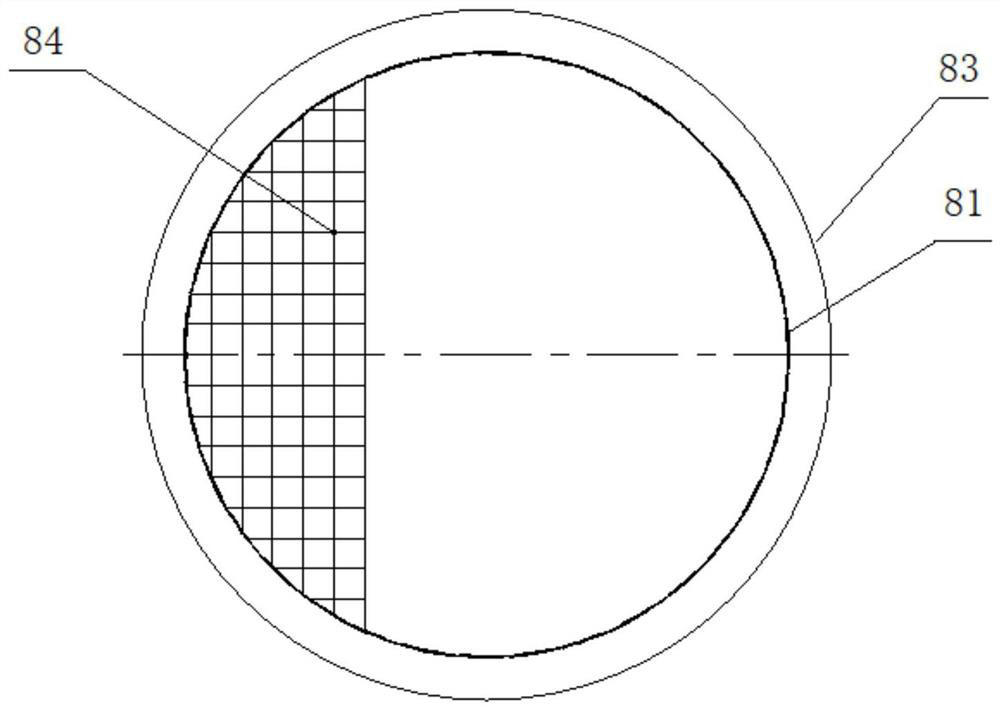

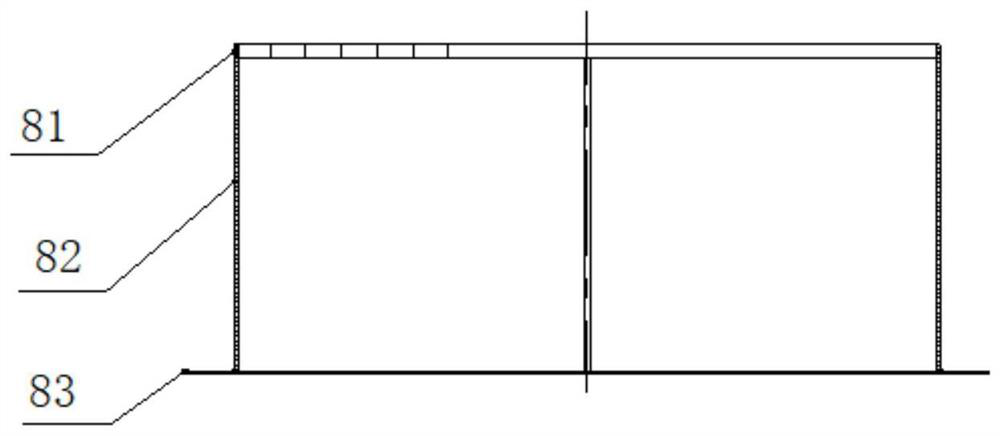

[0060] The airflow drying device 5 includes a crushing unit 51 and a drying unit 52, the crushing unit 51 and the drying unit 52 communicate with each other, and a dispersing distributor 8 is provided at the connection. The feeding device 7 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com