Anisotropy compensation MUSIC damage imaging method based on excitation focusing scanning

An anisotropic, imaging method, applied in instruments, measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as enhancement, and achieve the effect of improving positioning accuracy and signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

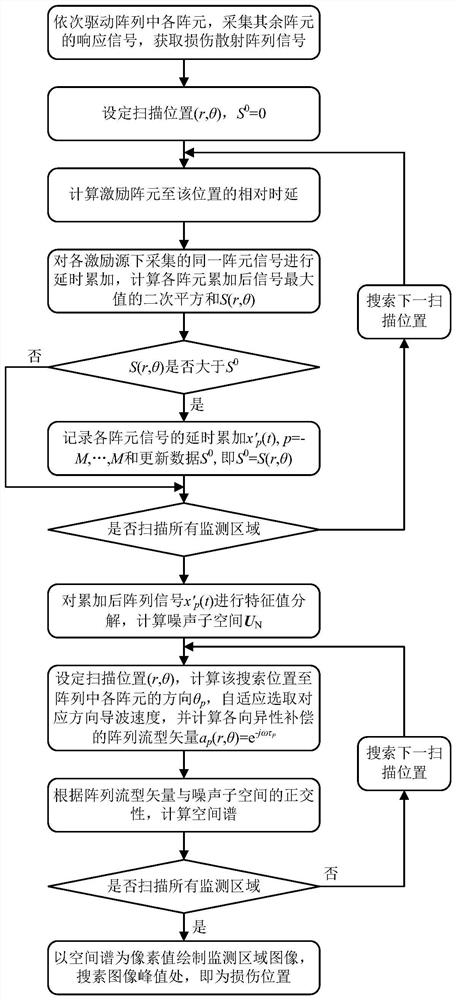

Method used

Image

Examples

Embodiment 2

[0086] Example 2 of the present invention: using a carbon fiber composite material plate as a strong attenuation anisotropic structure to conduct a damage localization experiment to illustrate its specific implementation process.

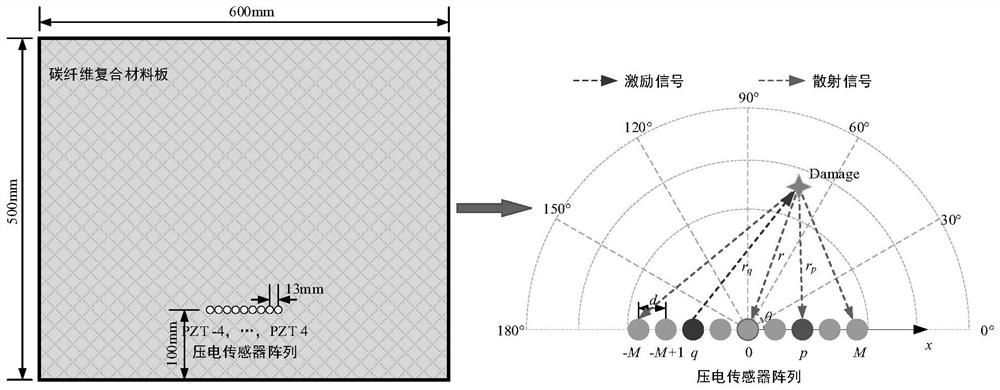

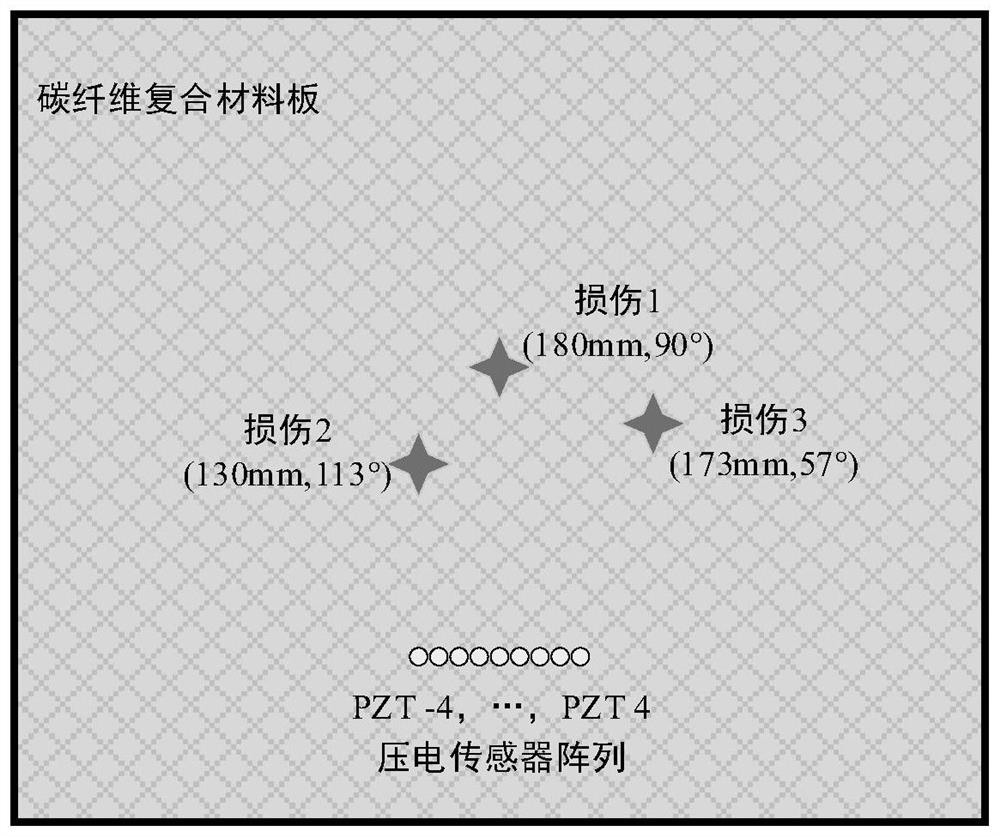

[0087] like figure 2 As shown, the size of the carbon fiber composite material board is 600mm×500mm×4mm, with a total of 24 layers. The thickness of each layer is 0.125mm, and the layering sequence is [45 / 0 / -45 / 90 / 0 / -45 / 0 / -45 / 0]s. A one-dimensional uniform linear array is arranged on the structure, including 9 array elements, the array element spacing is 13mm, and the names of each array element are PZT-4 to PZT 4. A polar coordinate system is established with the center of the array, namely PZT0, as the origin. At the same time, three damages were artificially simulated successively by pasting wave absorbing glue on the composite board, namely damage 1, damage 2 and damage 3. The locations of the three injuries are (180mm, 90°), (130mm, 113°) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com