Hot roller temperature control device for producing superfine denier nylon 66

A technology of production heat and temperature control device, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problem that the heating temperature of the hot roller does not reach the technical standard range, and the temperature detection process is easily disturbed by environmental factors , affecting the production quality of ultra-fine denier nylon 66, etc., to achieve the effect of fast and accurate temperature measurement, reduced impact, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

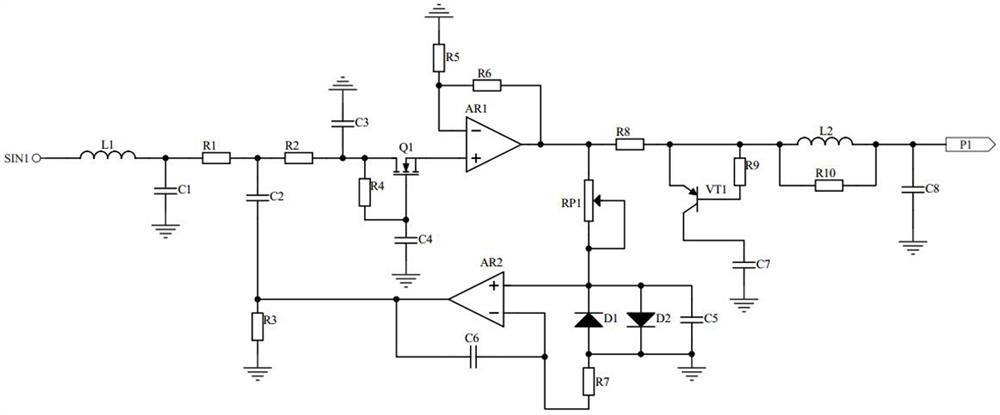

[0018] Regarding the aforementioned and other technical contents, features and effects of the present invention, the following references are attached with reference to figure 1 In the detailed description of the embodiments, this will become apparent. The structural contents mentioned in the following embodiments are all taken as reference to the accompanying drawings.

[0019] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0020] A thermal roller temperature control device for the production of ultra-fine denier nylon 66, comprising a roller body, a controller and a roller body temperature monitoring module, the roller body temperature monitoring module comprising an infrared temperature sensor arranged above the roller body, the infrared temperature The sensor is used to detect the heating temperature of the surface of the roller body, and its detection signal is sent to the filter amplifying circuit an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com