Combined type combined denitration equipment for sintering flue gas treatment and implementation method of combined type combined denitration equipment

A sintering flue gas and composite technology, applied in the direction of separation methods, chemical instruments and methods, mixers, etc., can solve the problems of small spraying range, affecting the processing structure, and poor processing efficiency, so as to improve the reduction efficiency and improve the flue gas Effect of improving purity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

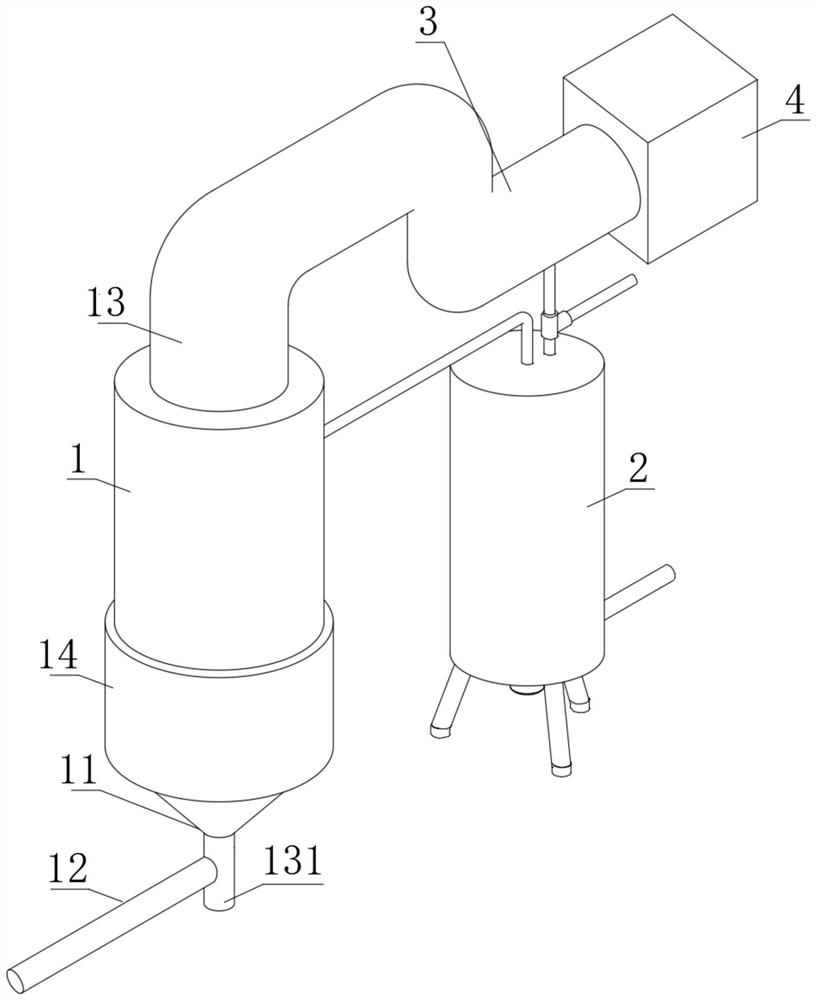

[0043] An implementation method of a composite combined denitration equipment for sintering flue gas treatment, comprising the following steps:

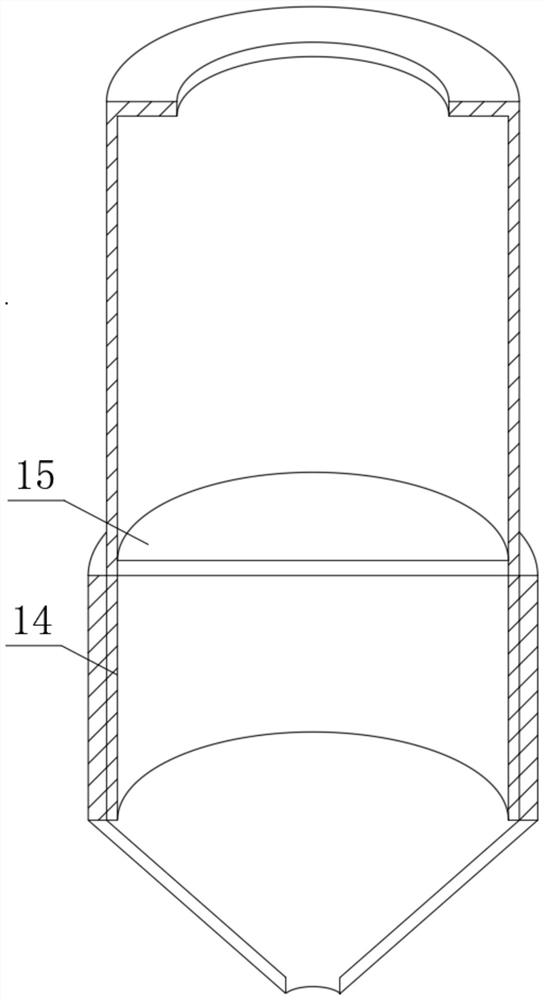

[0044] Step 1: The flue gas conveyed by the flue gas conveying pipe 12 processed through the flue gas inlet 11 is sent into the boiler 14 for heating, and the heated flue gas passes through the impurity filter screen 15 to filter out the particulate impurities and then enters the out-of-stock reaction tank 1 In the tank, effectively remove internal particulate impurities and improve the purity of flue gas;

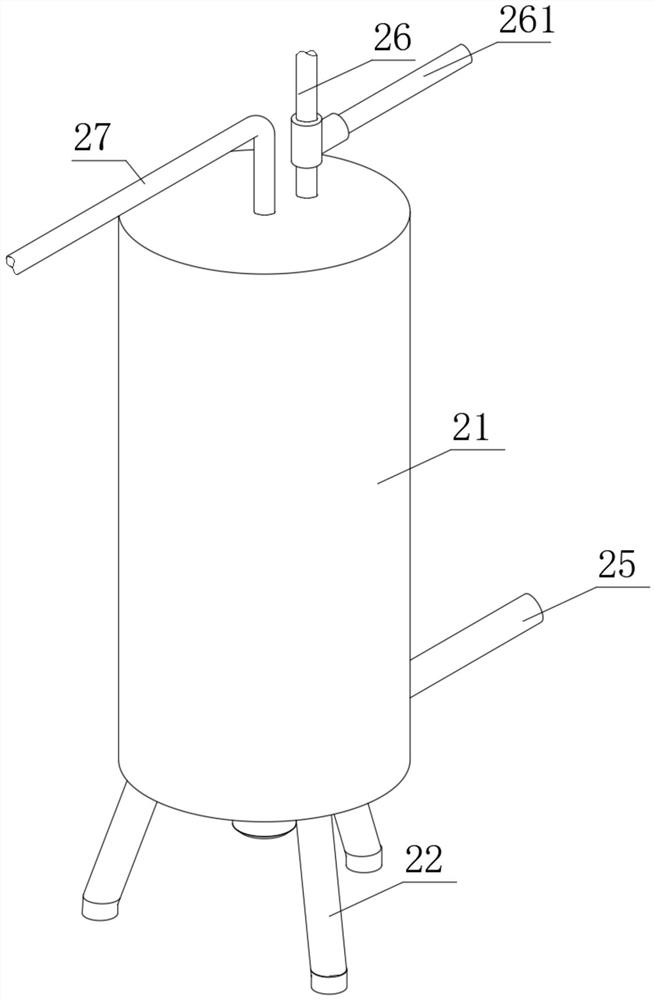

[0045] Step 2: Ammonia gas is injected into the storage tank 21 through the gas injection pipe 25, softened water is added through the water injection pipe 261, the screw agitator 24 is driven to rotate by the stirring motor 23, and the ammonia gas and the softened water are mixed and diluted to form a reducing agent. The shower assembly 27 is sprayed into the destocking reaction tank 1 to react with the flue gas, so that the amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com