Four-side winding packaging film cold cutting intelligent film detaching equipment

A packaging film and cold cutting technology, which is applied in the field of four-sided winding packaging film cold cutting intelligent film removal equipment, can solve the problems of low efficiency of tearing packaging film, difficulty in tearing, and failure to meet environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

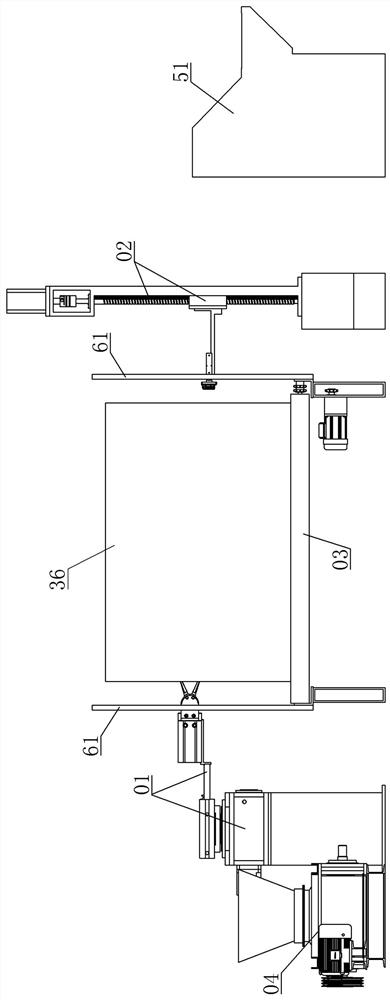

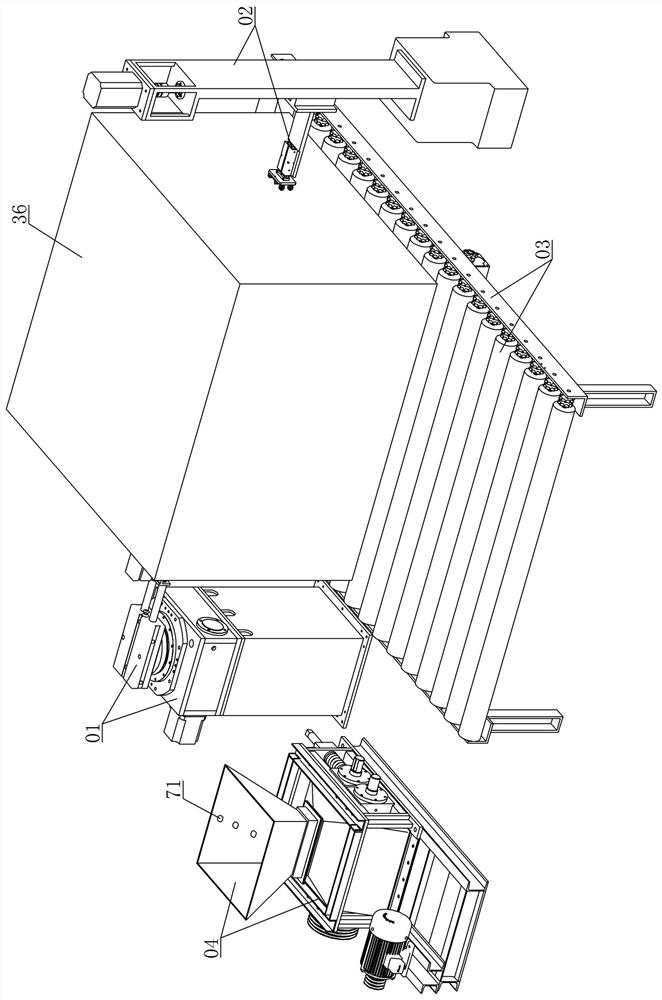

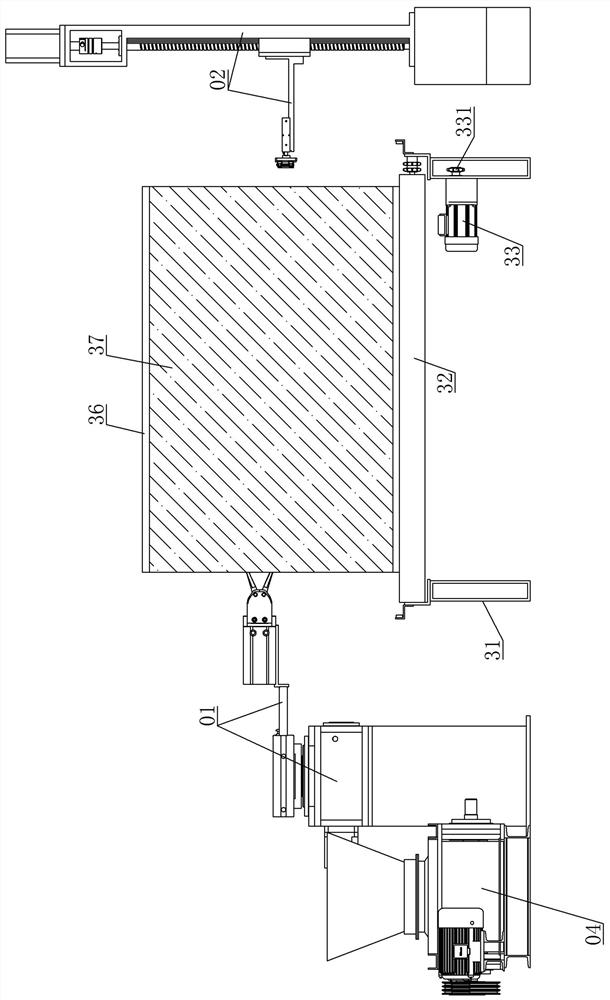

[0029] Embodiment 1, referring to Figures 1-13 in the description, is a four-sided wrapping film cold cutting intelligent film dismantling equipment, the film dismantling equipment includes a roller conveyor, a film grabbing device installed on one side of the roller conveyor, and a roller conveyor. Cutting device and master control system on the other side of the conveyor.

[0030] A rotating support is arranged in the middle of the upper end face of the shell bracket of the film grabbing device, the upper surface of the rotating support is horizontally fixedly connected with a double-piston-rod cylinder armour, and the outer ends of the two piston rods of the double-piston-rod cylinder armour are horizontally fixedly connected with clamping jaws The supporting plate, the clamping jaw supporting plate is provided with a clamping jaw mechanism, the housing bracket is provided with a driving mechanism for driving the rotation of the rotary support, and the rotary support is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com