Novel 4017 aluminum alloy sheet for coating material and preparation method thereof

An aluminum alloy and coating technology, applied in the field of aluminum alloy manufacturing, can solve problems such as poor fluidity and technical difficulty, achieve the effects of thorough slag removal, increase recycling efficiency, and solve the emission of harmful gas substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

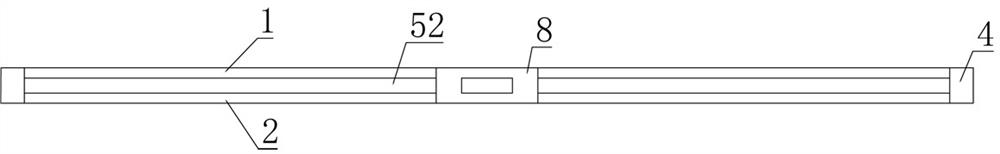

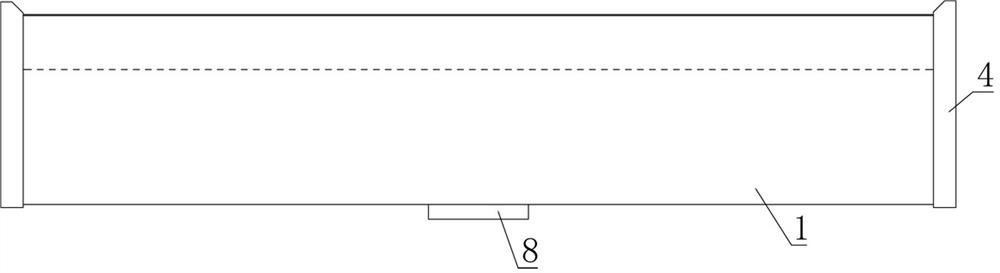

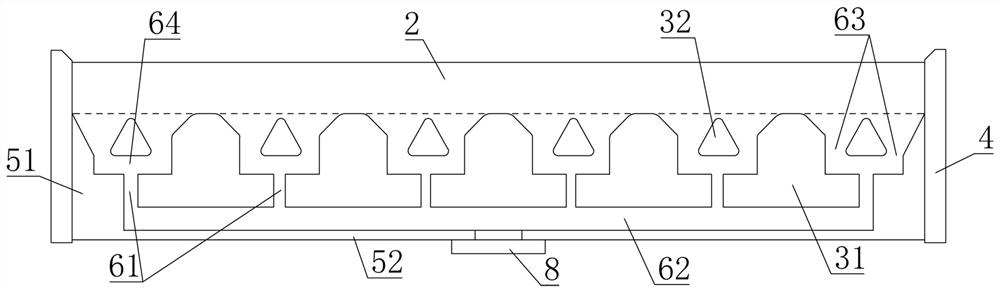

Image

Examples

Embodiment 1

[0049] In terms of mass percentage, the alloy chemical composition of the 4017 aluminum alloy sheet for the new coating material of this embodiment is: Si 1.4%, Fe 0.55%, Cu 0.17%, Mn 1.15%, Mg 0.45%, Cr 0.05% , Zn 0.1%, Ti 0.035%, and the balance is Al.

Embodiment 2

[0051] The preparation method of 4017 aluminum alloy sheet for coating material of embodiment 1, the steps are as follows:

[0052] a. Smelting: Add the raw material pure aluminum ingots and process wastes into the flame reverberatory furnace for heating and smelting, and control the melting temperature in the furnace to be 735-750 ° C. After all the raw materials in the furnace are melted, stir to remove the scum to obtain the original alloy liquid, wherein The purity of the pure aluminum ingot is ≥99.80%, and the mass percentage of the process waste is 80%;

[0053] Then add anhydrous magnesium chloride flux, Al-20Mn (20% pure Al-Mn master alloy, that is, the mass percentage of Mn in the Al-Mn master alloy is 20%), Al-20Si (20% pure Al-Si The master alloy, that is, the mass percentage of Si in the Al-Si master alloy is 20%) and Al-5Ti-1B wire are batched, and the batching temperature is 735-740 ° C. The alloy element composition of the 4017 aluminum alloy sheet blank for th...

Embodiment 3

[0069] In terms of mass percentage, the alloy chemical composition of the 4017 aluminum alloy sheet for the new coating material of this embodiment is: Si 1.375%, Fe 0.475%, Cu 0.145%, Mn 1.1%, Mg 0.35%, Cr 0.025% , Zn 0.05%, Ti 0.03%, and the balance is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com