Method for predicting ash content of clean coal in flotation process

A flotation process and prediction method technology, applied in the direction of prediction, instrumentation, data processing applications, etc., can solve the problem that clean coal ash cannot be detected effectively, accurately and quickly, and achieve real-time online continuous detection, accurate and fast detection, The effect of improving the utilization rate of mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention are specifically described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the present application, and together with the embodiments of the present invention, are used to explain the principles of the present invention, but are not used to limit the scope of the present invention.

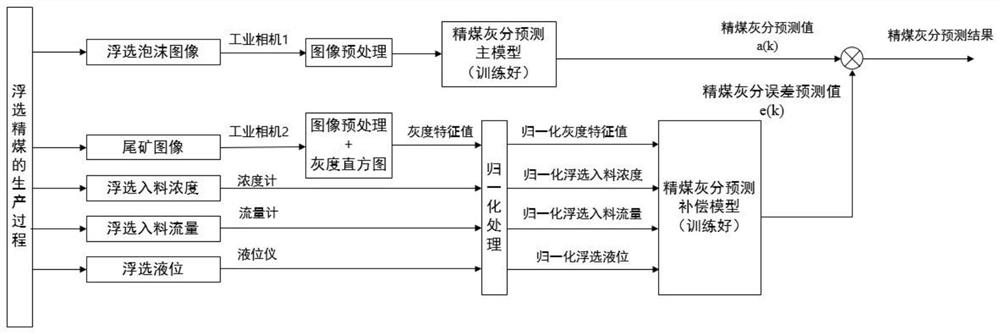

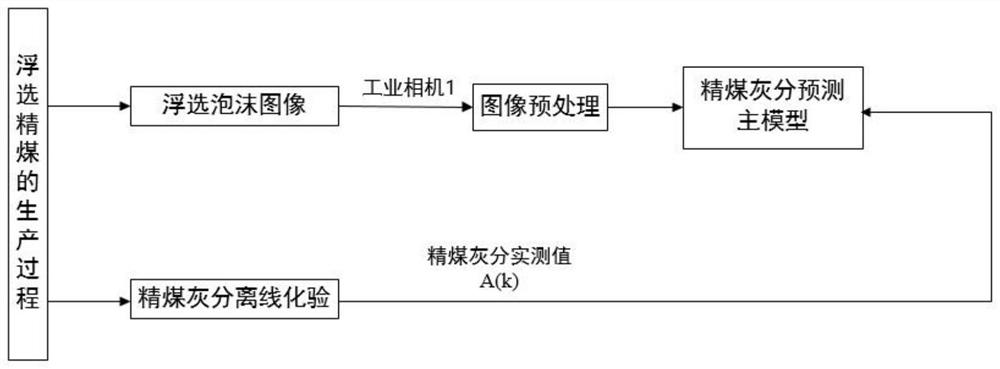

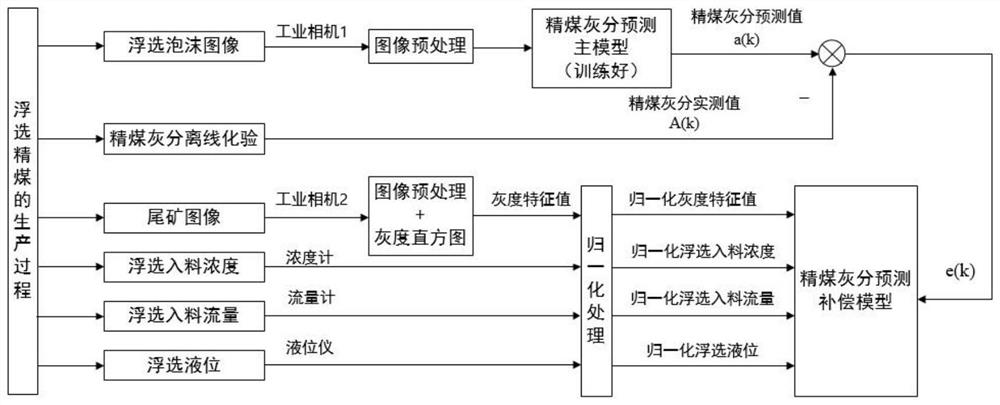

[0044] A specific embodiment of the present invention discloses a method for predicting the ash content of clean coal in a flotation process. The flow chart is as follows: figure 1 shown, including the following steps:

[0045] Step S1: collect data in real time, including flotation froth image, tailings image, flotation feed concentration, flotation feed flow and flotation liquid level;

[0046] Step S2: Input the flotation froth image collected in real time into the trained main model for predicting the clean coal ash content, and obtain the predicted value of clean coal ash conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com