Deoiling and hole-conditioning method of printed circuit board PTH (Plating Through Hole) process, alkaline degreasing and hole-conditioning agent and preparation method of alkaline degreasing and hole-conditioning agent

A printed circuit board, alkaline degreasing technology, applied in the direction of printed circuit manufacturing, printed circuit, printed component electrical connection formation, etc., can solve the problems of colloidal palladium adsorption, electroless copper plating cannot be carried out smoothly, and no copper on the hole wall , to achieve the effect of easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

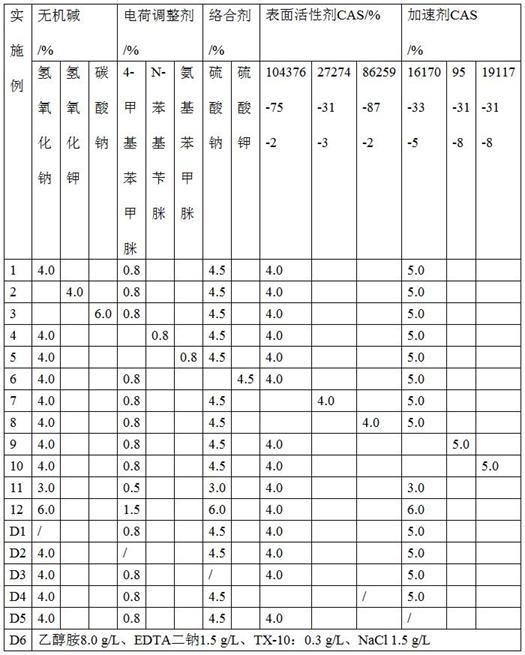

Examples

preparation example Construction

[0043] The invention also discloses a preparation method of the above-mentioned alkaline degreasing and pore-forming agent, comprising the following processes:

[0044] The above-mentioned inorganic base, charge regulator, inorganic salt complexing agent, nonionic surfactant and accelerator are added into a water solvent and mixed to obtain an alkaline degreasing and pore-forming agent.

[0045] The aqueous solvent is preferably deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com