Anti-seepage liquid spraying equipment for basement drainage

A technology for spraying equipment and anti-leakage, which is applied in liquid spraying devices, spraying devices, mixers with rotary stirring devices, etc., can solve the problems of urgent air environmental protection, health effects, environmental pollution, etc., and improve utilization efficiency. , Reduce the work intensity and achieve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

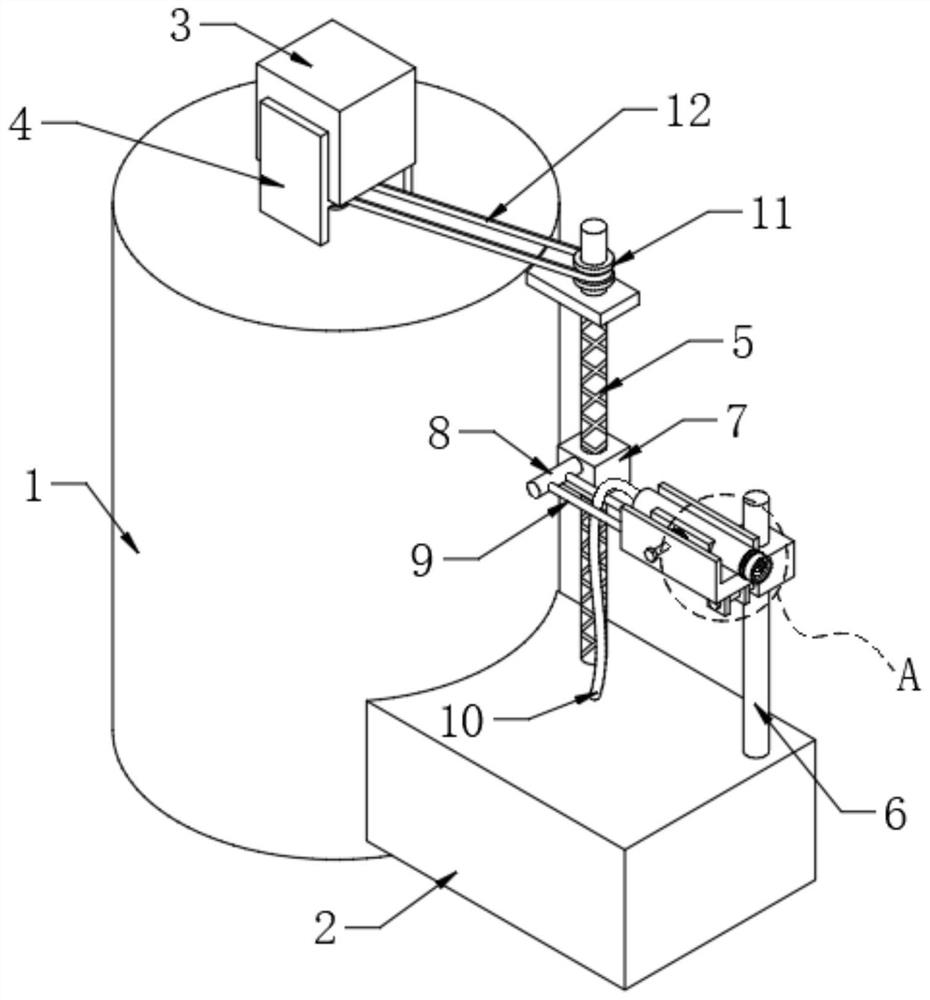

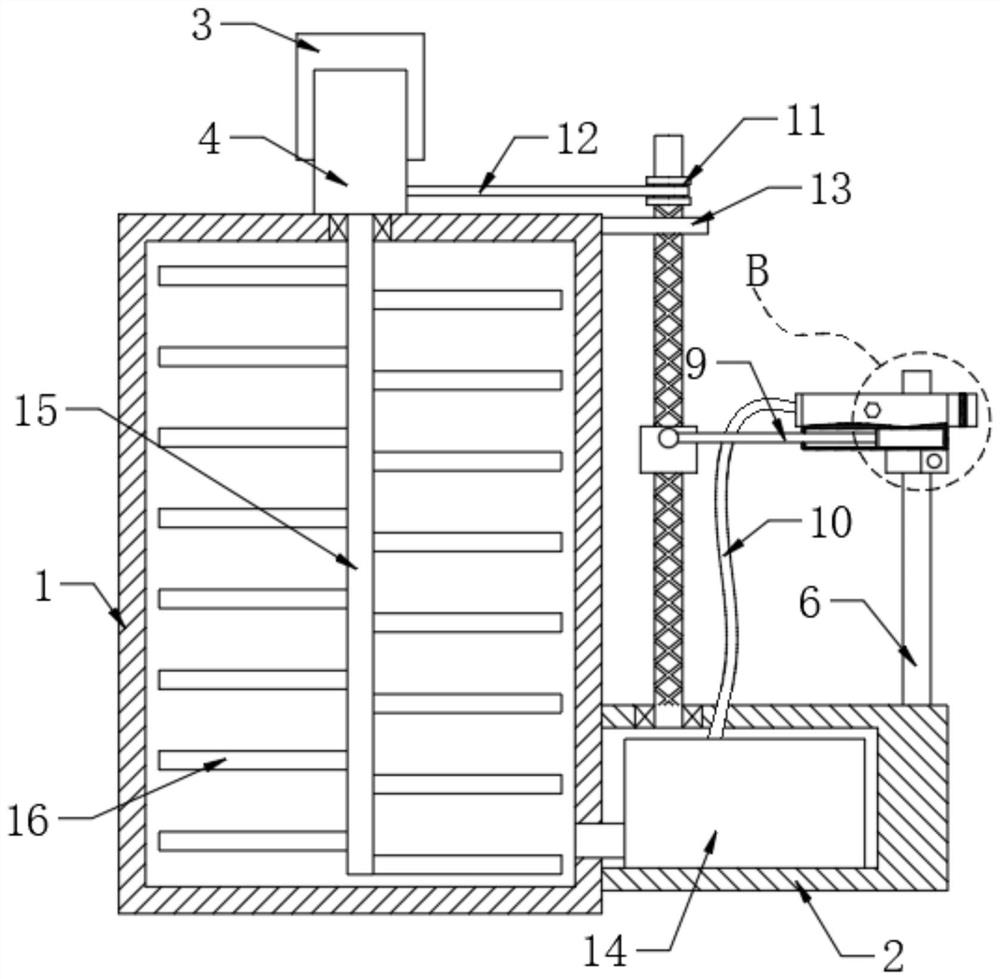

[0029] like Figure 1-6 As shown, a kind of anti-seepage liquid spraying equipment for basement drainage proposed by the present invention includes a paint storage tank 1 and an installation box 2 connected to the right side wall of the bottom of the paint storage tank 1, and the top of the installation box 2 is provided with a spraying Head 19. The inner cavity of the installation box 2 is provided with a pump body 14, and an infusion tube 10 is connected between the main body of the pump body 14 and the bottom inner cavity of the paint storage tank 1 and the input end of the spraying head 19. A rotating rod 15 is arranged in the cavity, and the top rod body of the rotating rod 15 penetrates the top wall of the paint storage tank 1 through a bearing. The surface of the rod body of the rotating rod 15 is provided with stirring rods 16, and the stirring rods 16 are evenly distributed in multiple groups. The top of the installation box 2 is provided with a direction adjustment...

Embodiment 2

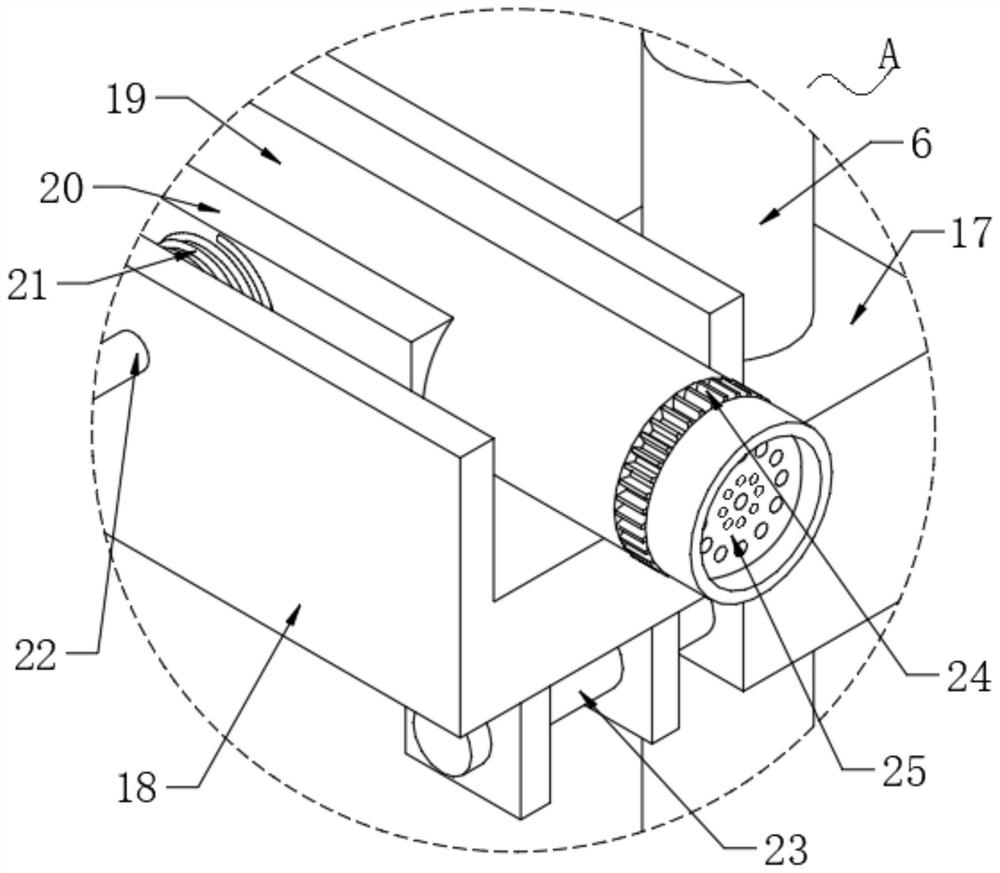

[0032] like figure 1 , figure 2 , image 3 , Figure 4As shown, the present invention proposes an anti-seepage liquid spraying device for basement drainage. Compared with the first embodiment, this embodiment also includes a direction adjustment mechanism including a reciprocating screw rod 5, a guide rod 6, a moving block 7, The rotating column A8, the connecting rod 9, the movable block 17, the placing seat 18, the rotating column B23, the movable cavity 27, the reciprocating screw rod 5 and the guide rod 6 are all installed on the top wall of the installation box 2, wherein the bottom of the reciprocating screw rod 5 The end rod body is installed in the top wall of the installation box 2 through bearings. And the moving block 7 is screwed on the surface of the rod body of the reciprocating screw 5, the movable block 17 is fixedly sleeved on the top rod body of the guide rod 6, and the rear end rod body of the rotating column A8 is rotated and installed in the front wall...

Embodiment 3

[0035] like image 3 , Figure 4 , Figure 5 , Image 6 As shown in the figure, an anti-leakage liquid spraying device for basement drainage proposed by the present invention, compared with the first and second embodiments, this embodiment also includes a clamping and fixing mechanism including a clamping plate 20, a limit spring 21. The control rod 22, the control block 26, the clamping plate 20 is arranged in the groove of the top wall of the placing seat 18, the control rod 22 is fixedly installed on a side wall of the clamping plate 20 away from the spraying head 19, the control rod 22 The rod body moves through the front side wall of the placing seat 18 , and the control block 26 is fixedly installed on the rod body at the end of the control rod 22 away from the clamping plate 20 , and the limit spring 21 is provided on the front side of the clamping plate 20 and the placing seat 18 In the cavity of the wall, and the limit spring 21 is sleeved on the surface of the rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com