Modularized robot for ship paint spraying and rust removal and control method thereof

A modular and robotic technology, applied in the field of bionic robots, can solve the problems that spraying and derusting robots cannot adapt, cannot enter small spaces, and cannot spray and derust, and achieve good production and application prospects, saving human resources, and high automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following combined with the attached picture, the technical solution of the present invention further explained.

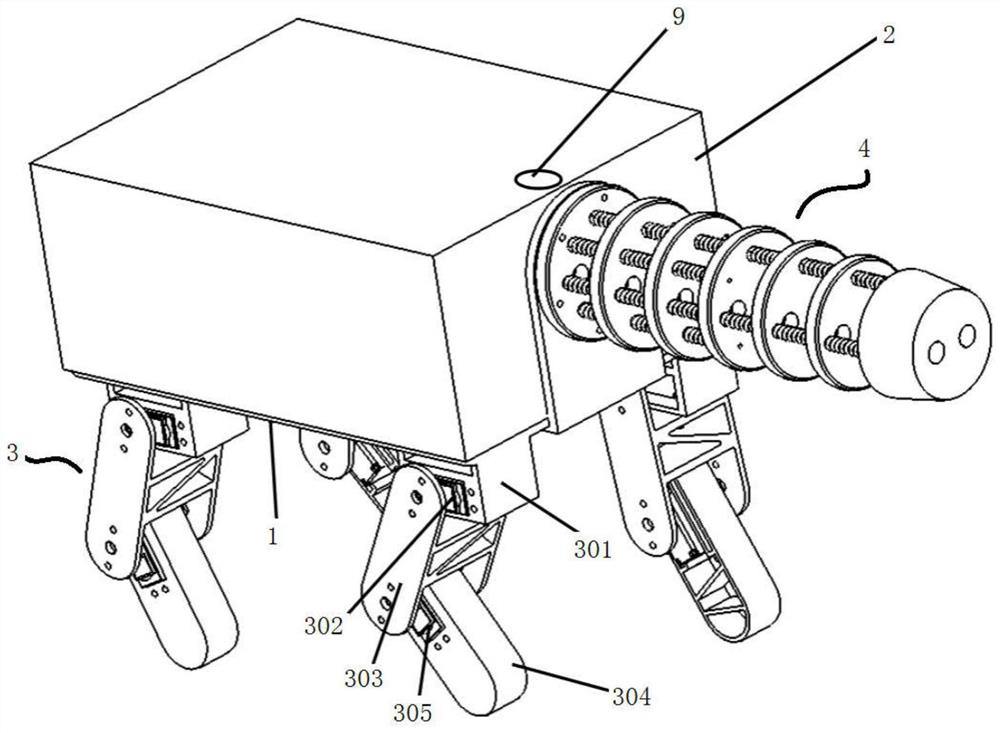

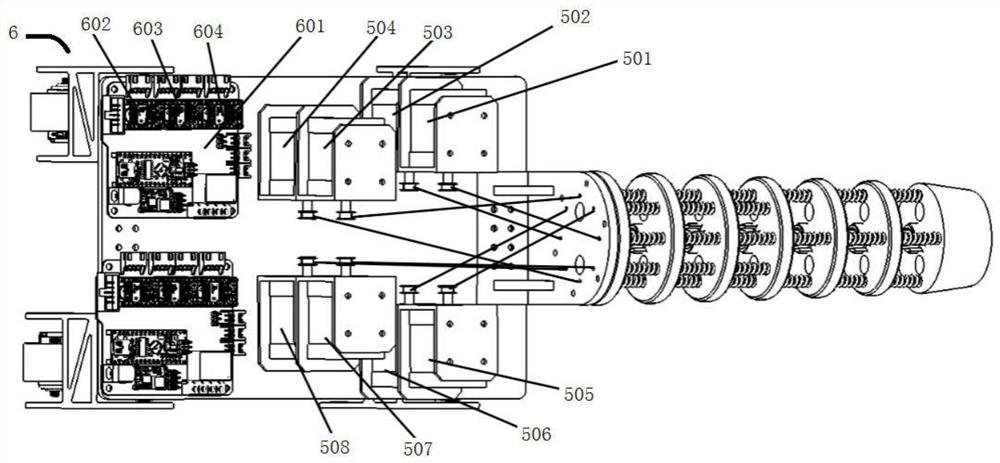

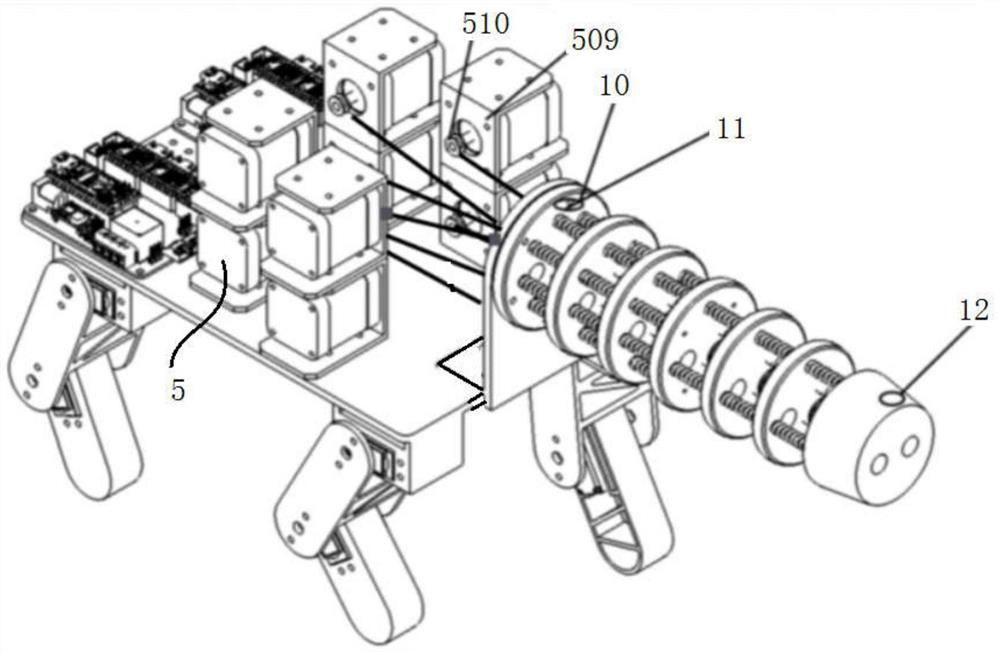

[0043] like figure 1 and figure 2 It is shown in, a robotic robot used for ship spray painting rust and rust removal of the present invention includes the body plate 1. Closed shell 2, bionic elephant leg 3, bionic elephant nasal spray painting mechanism 4. Spray paint power component 5, spray paint control component 6, bionic bionic Elephant nasal rust removal mechanism 7, rust removal control component 8, lidar 9, temperature sensor 10, first visual sensor 11, paint coating thickness sensor 12, second visual sensor 13, rust sensor 14, optical rough sensor 15, 15 And charging lithium battery box.

[0044] like image 3 It is shown that the closed case 2 cover in the present invention is set on the body plate 1. The welding process is used when the closed case is assembled with the body plate to do dustproof treatment. Install a transparent dust cover. Four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com