Regenerated powder doped 3D printing engineering spoil printing ink material based on spoil autocompounding technology and preparation method of regenerated powder doped 3D printing engineering spoil printing ink material

A technology of 3D printing and recycled powder, which is applied in the direction of additive processing, solid waste management, climate sustainability, etc., can solve the problem that recycled powder resources cannot be effectively used, so as to improve extrudability and reliability Constructive, improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

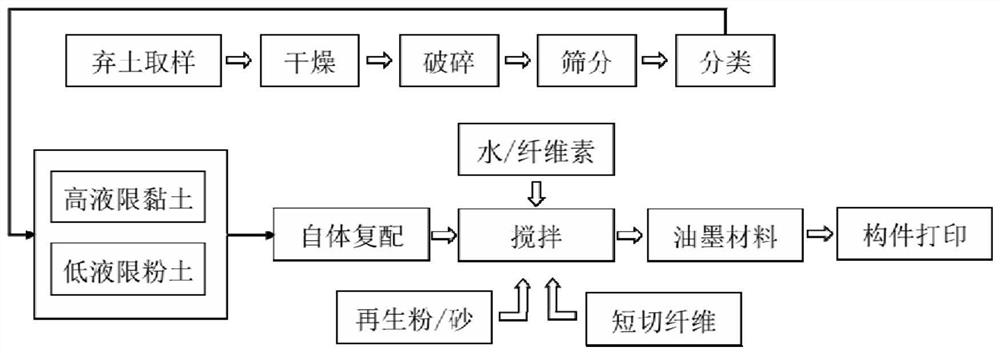

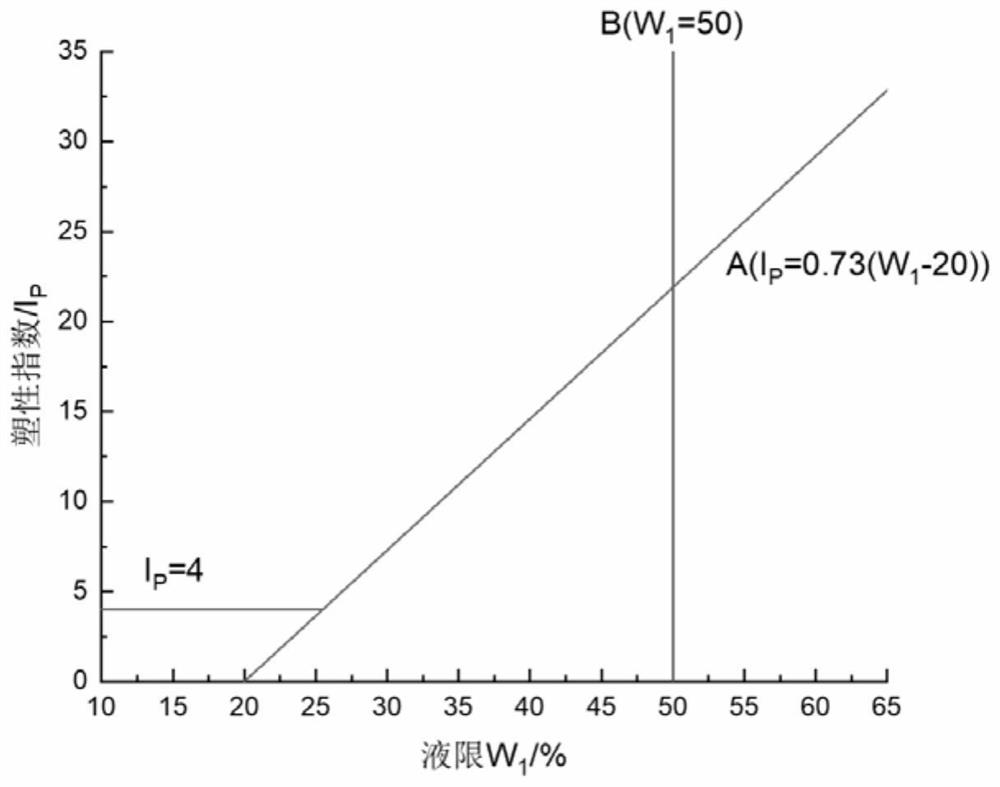

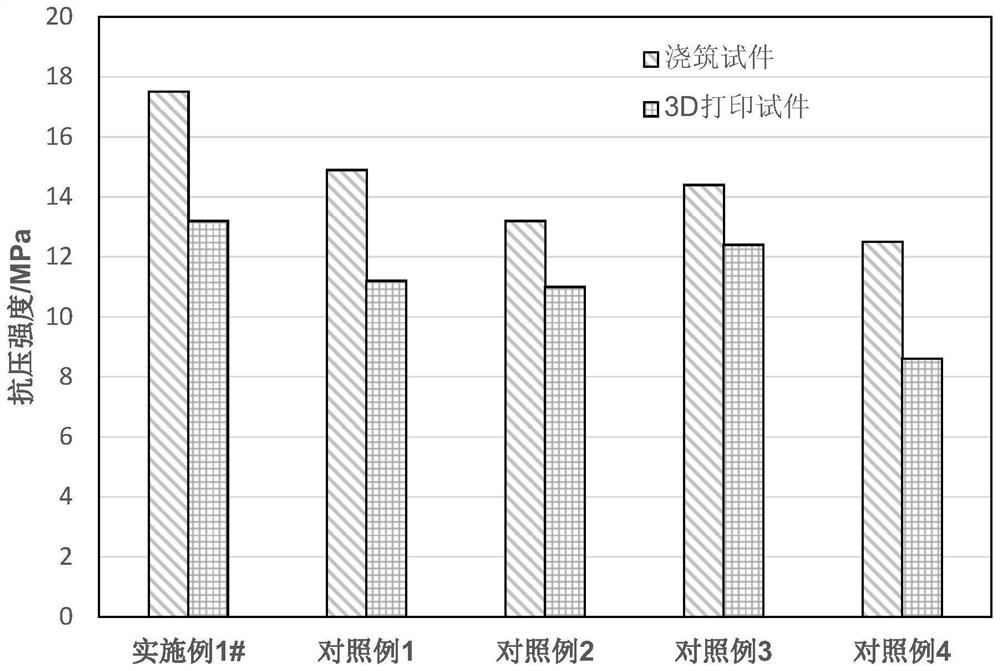

[0073] The engineering spoils from different sources were successively dried at 100°C, crushed, and sieved through a 0.15mm aperture screen. figure 2 The JTG E40-2007 soil classification method shown is used to classify the powder to obtain a high liquid limit clay powder and a low liquid limit silt powder, of which the liquid limit and plasticity index of the high liquid limit clay powder are 58.6% and 33.9, respectively. , the liquid limit and plasticity index of low liquid limit silt powder are 35.4% and 3.4, respectively.

[0074] A component of spoil ink material for 3D printing engineering based on spoil self-compounding technology, which, in parts by weight, includes the following components: 1 part of high liquid limit clay powder, 1 part of low liquid limit silt Powder, 0.01 part of lignosulfonate, 0.03 part of regenerated powder, 0.15 part of regenerated sand, 0.02 part of cellulose, 0.008 part of chopped fiber, and 0.8 part of water.

[0075] Among them, the lignos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com