Safe and continuous production method of sulphaguanidine

A production method and technology of sulfamidine, which is applied in the field of production process of chemical raw materials, can solve problems such as explosion and pressure increase, and achieve the effects of improving safety performance, stable reaction, and reducing online volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

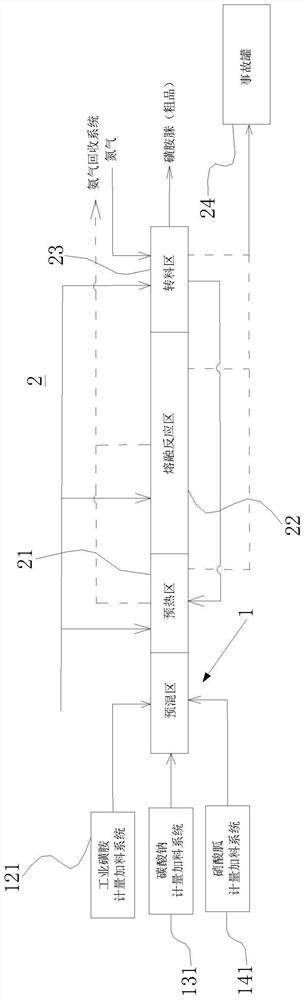

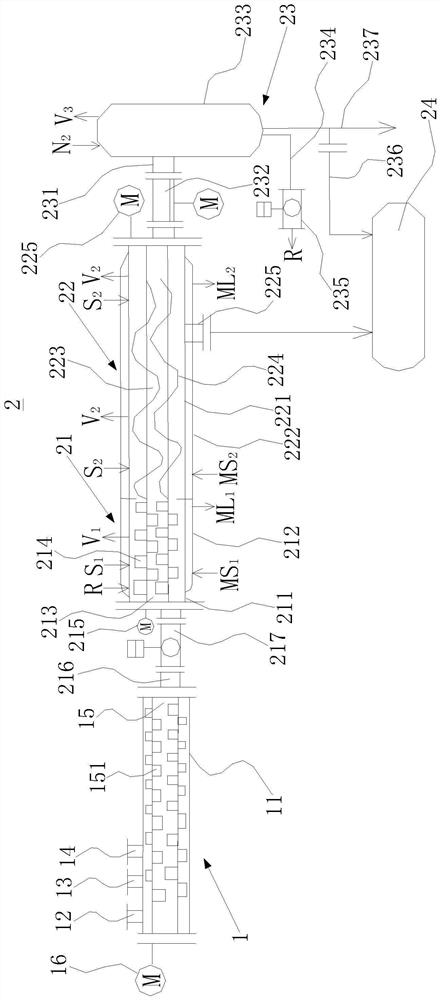

[0018] This embodiment provides a kind of safe continuous production method of sulfamidine, which is based on figure 1 and figure 2 Continuous reactor shown. The continuous reactor is a solid-phase melt-connected flow reactor, which mainly includes a premixing zone 1 and a reaction component 2 .

[0019] The premixing zone 1 is used for premixing the reaction raw materials, and includes a premixing pipe 11, a first stirring shaft 15 (ie, a first stirring shaft 15) rotatably installed in the premixing pipe 11 and having a first stirring protrusion 151 on the surface. A number of first stirring protrusions 151 are arranged on the surface of the shaft 15 to achieve full mixing of the reaction raw materials; the premixing pipe 11 is usually provided with a support structure for installing the first stirring shaft 15, and the first stirring shaft 15 is realized by bearings. rotatable, the same below), a first motor 16 installed on the premixing pipe 11 and connected with the fir...

Embodiment 2

[0030] The present embodiment provides a safe continuous production method for sulfamidine, which is basically the same as that in Example 1, except that: in step (d), the reflux ratio is 0.2:1; the purity of the final crude sulfamidine is 48.6%, The yield based on the raw material guanidine nitrate was 91%.

Embodiment 3

[0032] The present embodiment provides a safe continuous production method for sulfamidine, which is basically the same as that in Example 1, except that: in step (d), the reflux ratio is 1:1; the purity of the final crude sulfamidine is 62.3%, The yield based on the raw material guanidine nitrate was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com