Multi-thread coil reactor for strong exothermic reaction

An exothermic reaction and multi-thread technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve problems such as complex mechanisms and large heat release. Achieve the effect of safety in the reaction process, reduction of online material volume, and enhanced transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

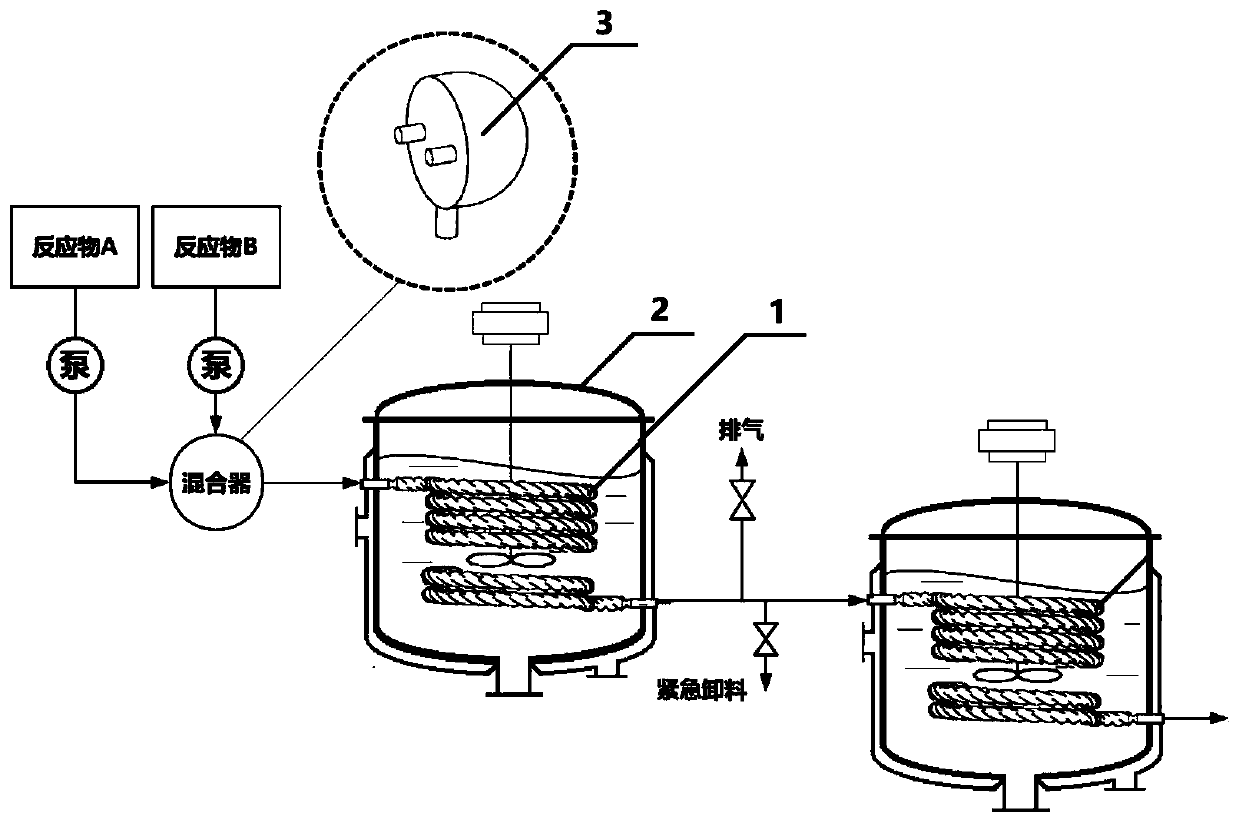

[0027] Example 1 see attached figure 1 , a multi-threaded coil reactor for strong exothermic reaction mainly includes a multi-threaded coil reactor 1, a heat exchange stirring tank 2, a spherical mixer 3 and a valve; the multi-threaded coil reactor 1 can provide a place for the reaction to occur; the heat exchange stirring tank 2 provides a place for fluid heat exchange, and the heat exchange effect can be enhanced through the stirring paddle; the spherical mixer 3 adopts a spherical reflection structure to realize two or more streams Rapid pre-mixing of fluids; the valve can realize functions such as exhaust and emergency discharge.

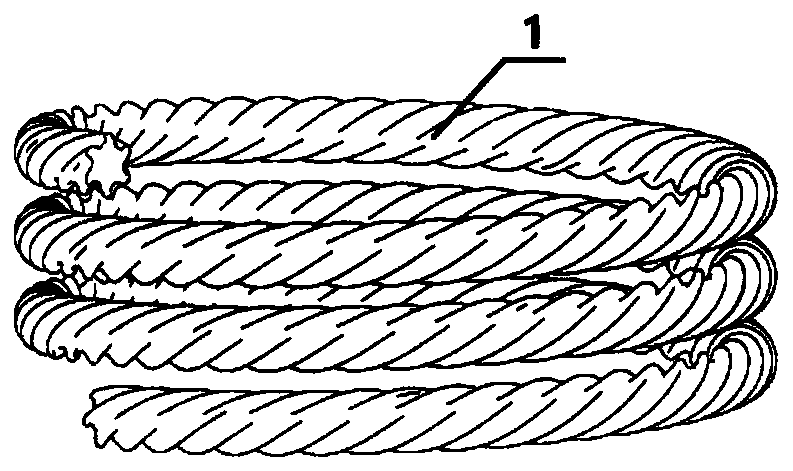

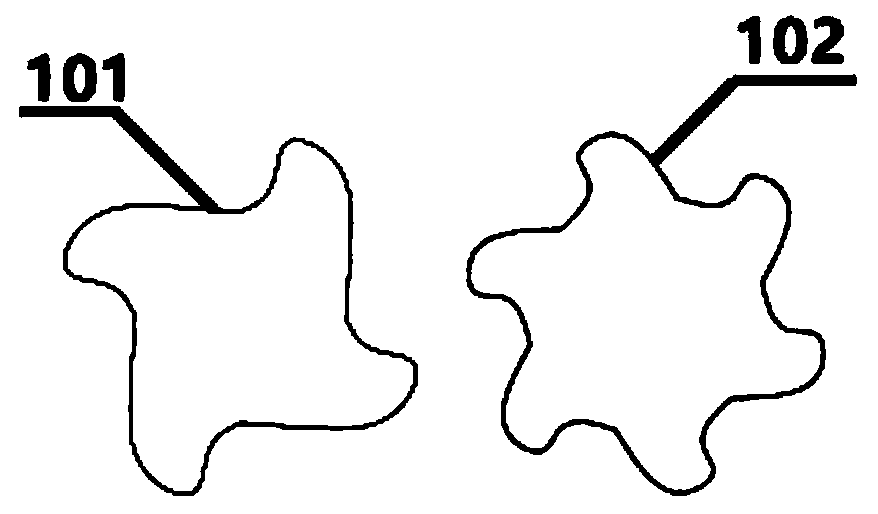

[0028] as attached figure 2 As shown, the core of a multi-threaded coil reactor for strongly exothermic reactions is the multi-threaded coil reactor 1 . According to different reaction characteristics, different structural parameters can be selected: the number of threads is 2-10, the outer diameter is 10-100mm, the groove depth is 2-20mm, an...

no. 2 example

[0034] Use a multi-threaded coil reactor for the nitration reaction of energetic compounds: the reaction is a strong exothermic reaction, and a stirred tank is used for heat exchange; when the reactor uses a four-thread coil, the outer diameter is 16mm and the inner diameter is 9mm, the lead is 35mm, and the length of the tube is 5m; the coil diameter is 400mm, the pitch is 20mm, and the number of turns is 5 turns; the feed temperature of the reaction solution is -10°C, and the temperature of the heat exchange carrier in the stirring tank is -16°C. Under this operating condition, the reaction time was controlled at 15 minutes. The conversion rate of reactants can reach more than 90%, and the product yield is about 60%. Compared with the 12mm circular tube reactor with the same cross-sectional area, the yield increased by 5 percentage points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com