Method for preparing light stabilizer 2020 by skeleton method

A technology of light stabilizer and skeleton method, applied in the field of skeleton method to prepare light stabilizer 2020, can solve problems such as product performance decline, large proportion of macromolecular and small molecule products, and complex product composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

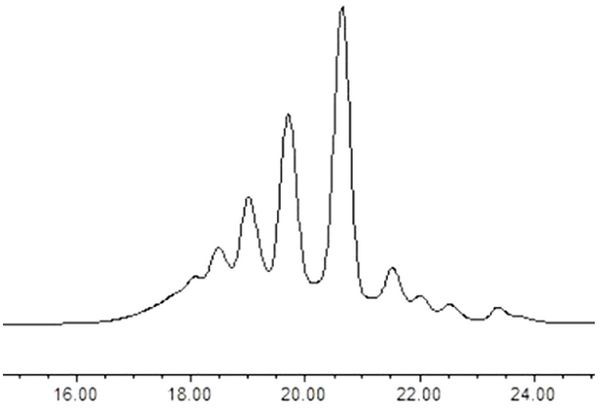

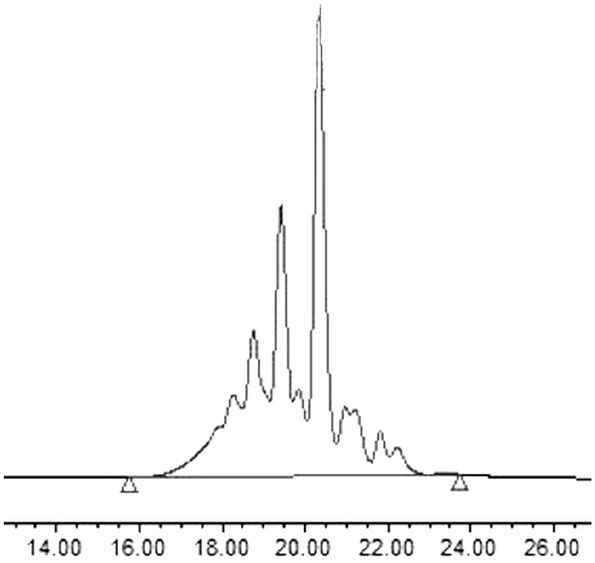

Image

Examples

Embodiment 1

[0045] Invest in 265g of dysmane, 92g triacyeocyanine in the reactor, stir well, cool to 0 ° C, and start adding 98.75g hepimramine; After the addition, stop stirring, static water separation, get the solution of the intermediate 1, and the income is burned in the bottle;

[0046] Invest in the reactor 159g dyshayne, 197.5g hebramine, keep stirring, heat up to 40 ° C, and then add an intermediate 1 solution; after the drip is added to 80 ° C Add 75g liquid. After the liquid and alkali droplets are added, the water divide is split to get the solution of the intermediate 2;

[0047] Invest in the intermediate 2 solution of 106g orthopramine and 75g liquid alkali, increase the temperature to 180 ° C for 3h, and then static water separation to obtain the solution of the intermediate 3;

[0048] Reduce the solution of the intermediate 3 to 0 ° C, and then slowly and evenly add 75g tritetchocyanine; after the addition, the heat preservation is stirred for 1h to get the solution of the i...

Embodiment 2

[0053] Invest in 265g of dysmane, 92g triacyeocyanine in the reactor, stir well, cool to 0 ° C, and start adding 98.75g hepimramine; After the addition, stop stirring, static water separation, get the solution of the intermediate 1, and the income is burned in the bottle;

[0054] Invest in the reactor 159g of dyshayne, 158g hebramine, keep stirring, heat up to 40 ° C, and then add an intermediate 1 solution; after the drip is added to 80 ° C 75g liquid alkali. After the liquid and alkali droplets are added, the water divide is split to get the solution of the intermediate 2;

[0055] Invest in the intermediate 2 solution of 106g orthopramine and 75g liquid alkali, increase the temperature to 180 ° C for 3h, and then static water separation to obtain the solution of the intermediate 3;

[0056] Reduce the solution of the intermediate 3 to 0 ° C, and then slowly and evenly add 64.4g tritetchocyl chloricocyan; after the addition, the heat preservation is stirred for 1h to get the so...

Embodiment 3

[0061] Invest in 265g of dysmane, 92g triacyeocyanine in the reactor, stir well, cool to 0 ° C, and start adding 98.75g hepimramine; After the addition, stop stirring, static water separation, get the solution of the intermediate 1, and the income is burned in the bottle;

[0062] Invest in the reactor 159g dyshayne, 197.5g hebramine, keep stirring, heat up to 40 ° C, and then add an intermediate 1 solution; after the drip is added to 80 ° C Add 75g liquid. After the liquid and alkali droplets are added, the water divide is split to get the solution of the intermediate 2;

[0063] Invest in the intermediate 2 solution of 106g orthopramine and 75g liquid alkali, increase the temperature to 180 ° C for 3h, and then static water separation to obtain the solution of the intermediate 3;

[0064] Reduce the solution of the intermediate 3 to 0 ° C, and then slowly and evenly add 82.8g tritetchocyl chlorylocyl; after the addition, the heat preservation is stirred for 1h to get the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com