High-strength composite aluminum alloy multi-strand stranded welding wire and stranded structure thereof

A technology of multi-strand stranded welding wire and aluminum alloy, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems of difficulty in melting welding and lack of 7 series aluminum alloy, and achieve good wire feeding stability and increase Yield, effect of refining recrystallized grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

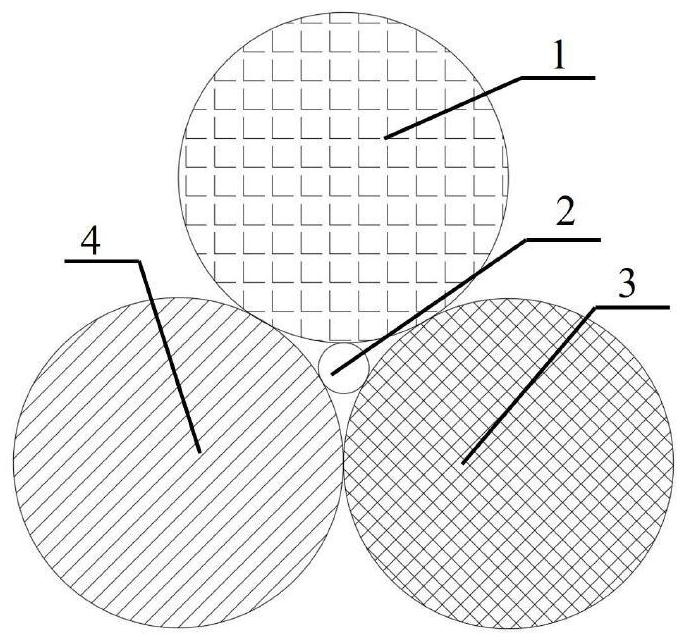

[0037] Example 1 (see Figure 1-4 ): a high-strength composite aluminum alloy multi-strand stranded welding wire in this embodiment is a 1+3-strand stranded structure, and the structure is as follows figure 1 As shown, the 1+3 stranded structure is formed by twisting one welding wire in the center and three welding wires in the outer ring, the four welding wires are tangent to each other, and the one welding wire in the center is pure Zn Welding wire, the three welding wires in the outer ring are ER1100 welding wire, ER5083 welding wire and ER2319 welding wire, wherein the ratio of the diameter of pure Zn welding wire to ER1100 welding wire, ER5083 welding wire and ER2319 welding wire is 1:6.464:6.464:6.464;

[0038] The chemical composition and mass percentage of the 1+3 strand stranded structure high-strength composite aluminum alloy multi-strand stranded welding wire are shown in Table 1;

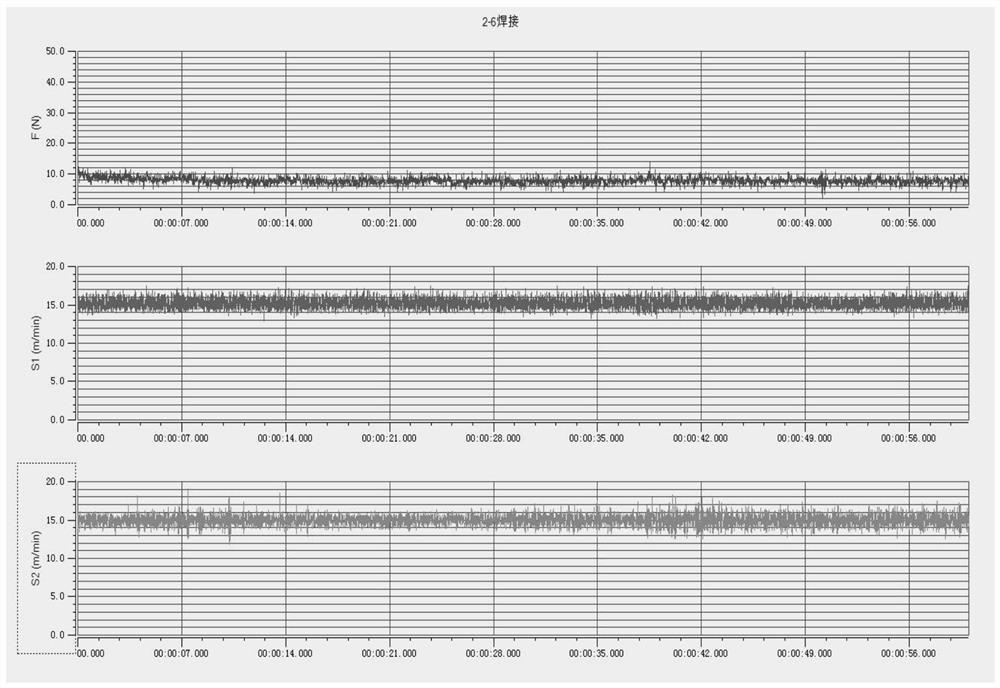

[0039] The above 1+3 stranded structure high-strength composite aluminum alloy mult...

Embodiment 2

[0042] Example 2 (see Figure 5-8 ): a high-strength composite aluminum alloy multi-strand stranded welding wire in this embodiment is a 1+3+3-strand stranded structure, the structure is as follows Figure 5As shown in the figure, the 1+3+3 stranded structure consists of 1 welding wire in the center, 3 welding wires in the second circle and 3 welding wires in the third circle, and the 3 welding wires in the second circle are stranded. The 1 welding wire in the center is wrapped, and the 4 welding wires are tangent to each other, and the 3 welding wires of the third circle are respectively circumscribed to the adjacent two of the 3 welding wires of the second circle, so The three welding wires in the third circle have the same diameter as the one in the center, the one in the center is pure Zn welding wire, the three welding wires in the second circle are all ER1100 welding wires, and the three welding wires in the third circle are ER1100 welding wires. The welding wires are p...

Embodiment 3

[0047] Example 3 (see Figure 9-12 ): a high-strength composite aluminum alloy multi-strand stranded welding wire in this embodiment is a 4×1+6-strand stranded structure, the structure is as follows Figure 9 As shown in the figure, the 4×1+6 stranded structure is formed by twisting 6 welding wires of the outer ring and 4 welding wires of the inner ring, and two adjacent ones of the 6 welding wires of the outer ring are tangent to each other , the adjacent 2 of the 4 welding wires of the inner ring are tangent to each other, the circumscribed circles of the 4 welding wires of the inner ring coincide with the inscribed circles of the 6 welding wires of the outer ring, and the 4 welding wires of the inner ring They are 2 pure Zn welding wires, 1 AZ91 Mg wire, and 1 pure Cu welding wire. The 6 welding wires in the outer ring are all ER1100 welding wires, of which 2 pure Zn welding wires are not adjacent. ER1100 welding wire and pure Zn welding wire, The diameter ratio of AZ91 Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com