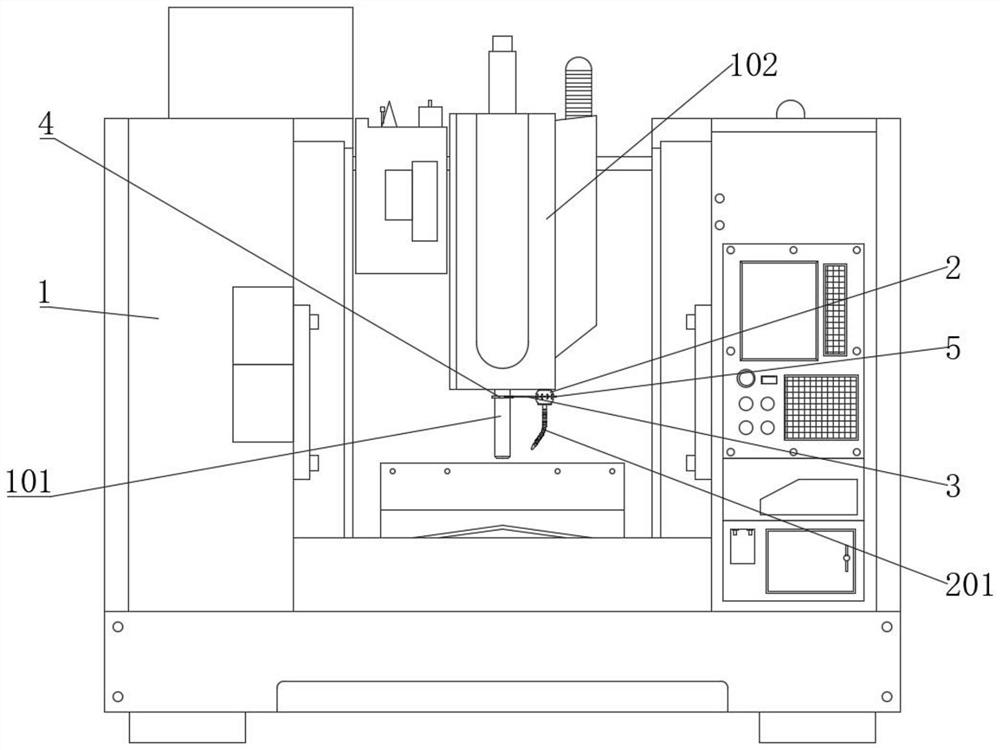

Machining center with synchronous temperature sensing type cutting fluid auxiliary device

A technology of machining centers and auxiliary devices, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as affecting the stability of metal cutting quality, reducing tool life, increasing environmental pollution, etc. The effect of cutting quality, improving tool life and improving heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

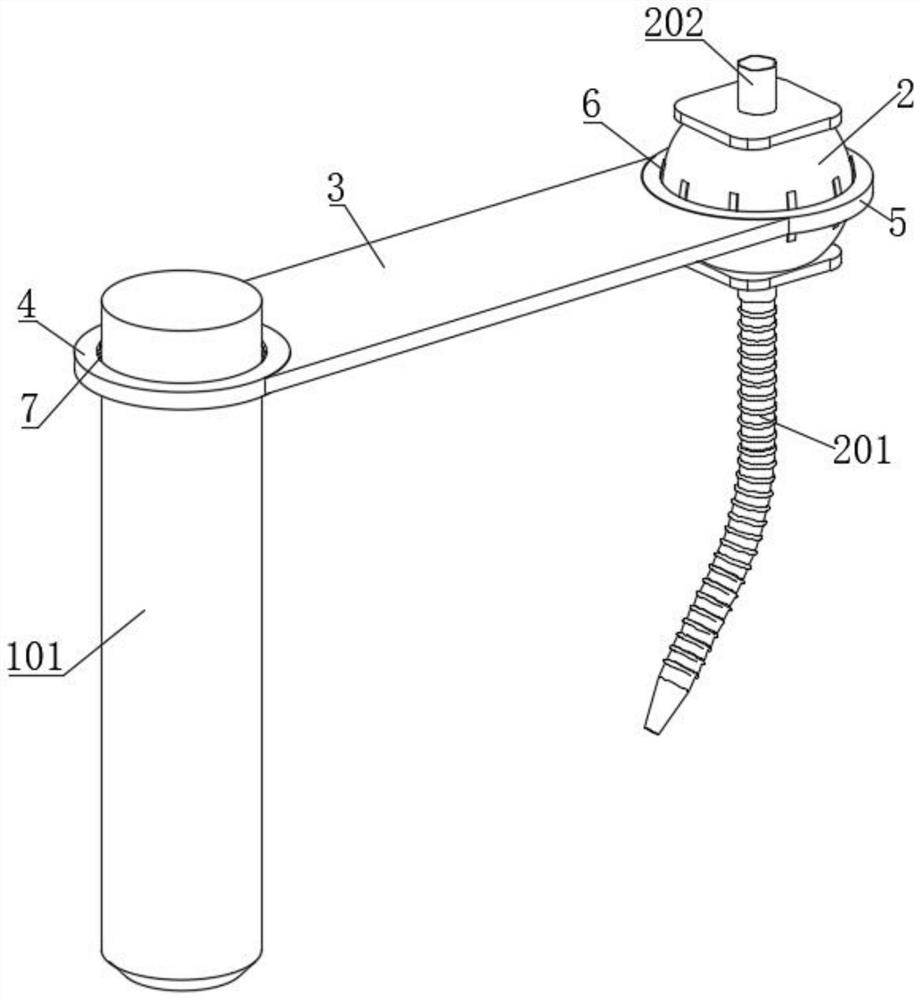

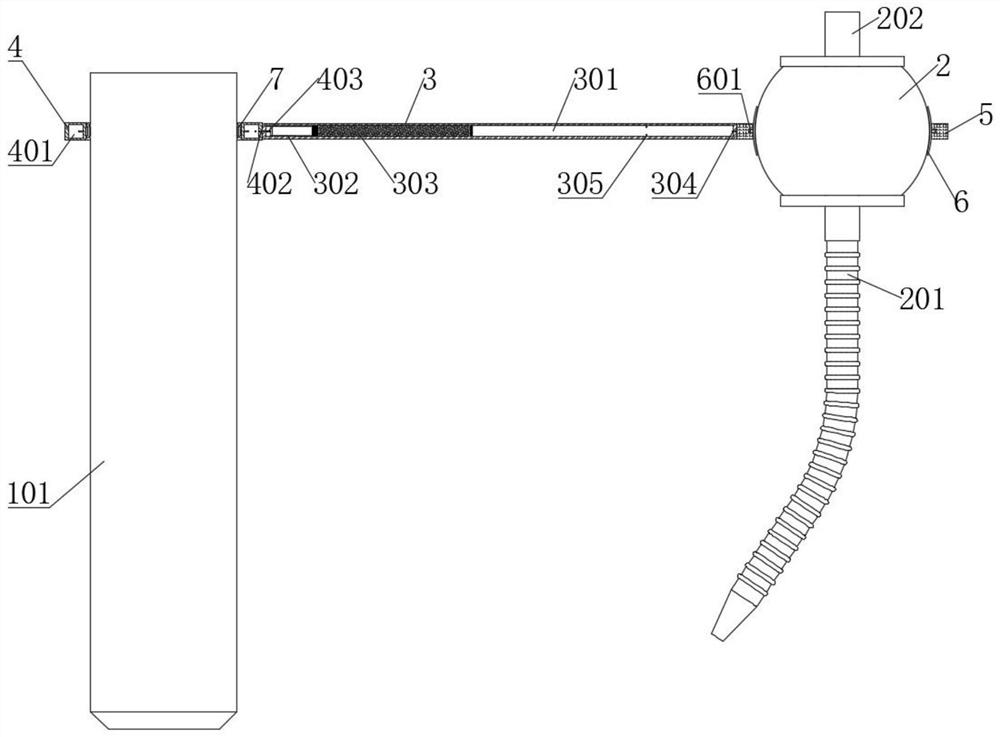

[0046] see Figure 1-10 , a machining center with a synchronous temperature-sensing cutting fluid auxiliary device, including a machining center body, a spindle sheath and a cutting tool located on the lower side of the spindle sheath are arranged in the machining center body, and the lower end of the spindle sheath is fixedly connected with a cutting tool located on the cutting edge. The saturated adjustment bag on the right side of the cutter, the outer end of the saturated adjustment bag is fixedly connected with a plurality of flexible tension air strips, the outer end of the flexible tension air strip is fixedly connected with a lining ring, and the left end of the lining ring is fixedly connected with a flexible tension air strip. The temperature-sensing synchronous connecting plate is fixedly connected to the left end of the temperature-sensing synchronous connecting plate with a tool temperature-sensing ring sleeved on the outside of the machining center body, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com