Layered crushing equipment for plastic recovery

A technology of plastic recycling and crushing equipment, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc. It can solve the problems of unsatisfactory crushing effect, difficult plastic degradation, and long natural degradation time, so as to achieve uniform and thorough crushing and convenient Processing time, the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

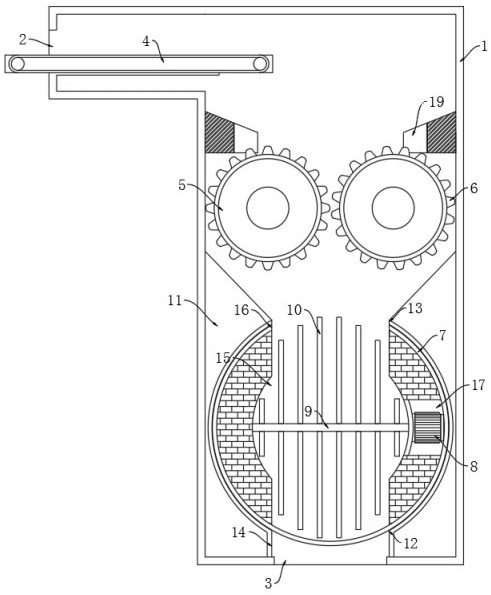

[0033] Please refer to figure 1 , a layered crushing equipment for plastic recycling, including a crushing box 1 and a conveyor 4, the crushing box 1 is provided with a feeding port 2 and a discharging port 3, the conveyor 4 is installed inside the feeding port 2, and the conveyor 4. It is used to convey materials to the inner cavity of the crushing box 1. The inner cavity of the crushing box 1 is provided with:

[0034] The coarse crushing mechanism is used for primary crushing of the materials entering the crushing box 1;

[0035] The material guide block 11, the material guide block 11 is fixedly installed below the coarse crushing mechanism, the inside of the material guide block 11 is provided with a rotating cavity 12, the top of the material guide block 11 is provided with a first inlet 13, and the bottom of the material guide block 11 is provided with There is a discharge port 14, the first inlet 13 is connected to the rotating cavity 12, and the discharge port 14 is ...

Embodiment 2

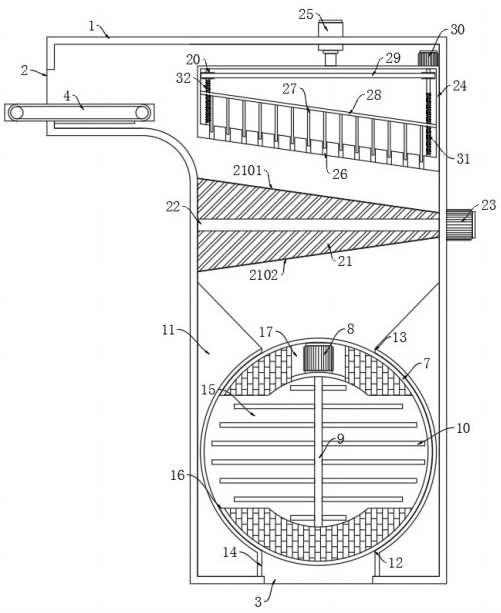

[0045] refer to figure 2 , Specifically, the crushing mechanism includes a material bearing part, an extruding part and a cutting part located inside the extruding part;

[0046] The material-bearing part includes a material-bearing plate 21 , a rotating shaft 22 and a rotating motor 23 . The four side walls of the material-bearing plate 21 are in contact with the four inner walls of the crushing box 1 , and the material-bearing plate 21 is used to receive the drop from the conveyor 4 . The material bearing plate 21 is fixedly sleeved on the outside of the rotating shaft 22, the rotating motor 23 is fixedly installed on the outer wall of the crushing box 1, and the output shaft of the rotating motor 23 is drivingly connected to the rotating shaft 22, and the end of the rotating shaft 22 is connected to the crushing box 1. The inner wall of the box 1 is connected in rotation;

[0047] The extrusion part includes a extrusion box 24 and a lifting cylinder 25. The bottom of the ...

Embodiment 3

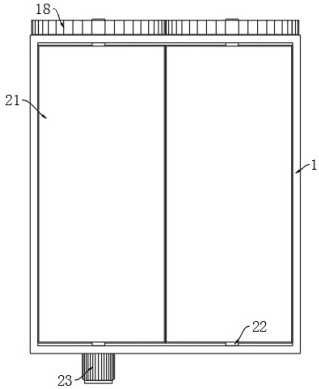

[0060] refer to figure 2 - image 3 , Specifically, the number of the material bearing plate 21 and the number of the rotating shaft 22 is set to two, the two rotating shafts 22 are equipped with a transmission gear 18, the transmission gear 18 is located outside the crushing box 1, and the two transmission gears 18 are mutually mesh.

[0061] Specifically, the axial length of the rotating drum 7 is greater than the radial length of the rotating drum 7 , and a plurality of transmission shafts 9 are arranged inside the fine crushing chamber 15 , and the rotating blades 10 are installed outside the plurality of transmission shafts 9 .

[0062] In the above-mentioned embodiment, the number of the material bearing plate 21 is one, and it rotates in one direction under the driving of the rotating shaft 22, so that the loading part 2101 and the unloading part 2102 of the material bearing plate 21 are exchanged, so that the material For blanking, in order to ensure the smooth rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com