Heavy truck drive axle structure assembly with high transmission efficiency

A transmission efficiency and drive axle technology, which is applied in the field of high transmission efficiency heavy truck drive axle structure assembly, can solve the problems of not considering the loss of transmission power, increasing user cost, low transmission efficiency of the bridge assembly, etc., to achieve improved assembly Transmission efficiency, improved rotation stability, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For better understanding and implementation, the present invention is described in detail below with reference to the accompanying drawings.

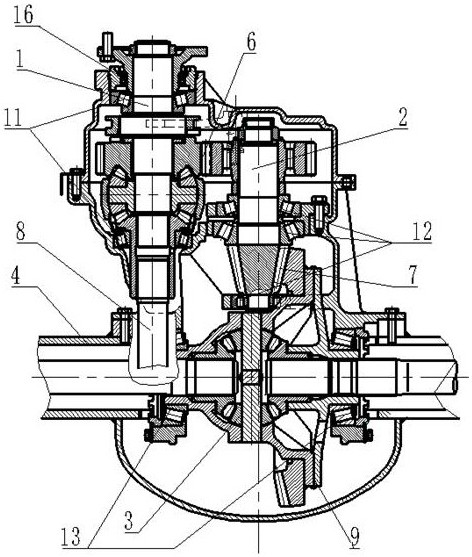

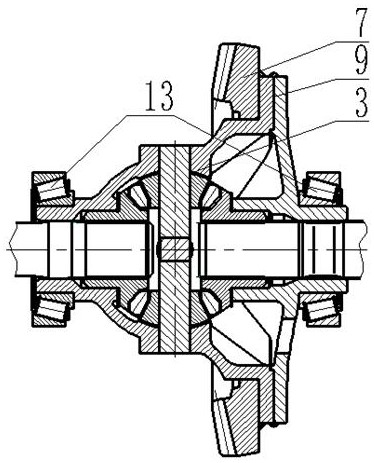

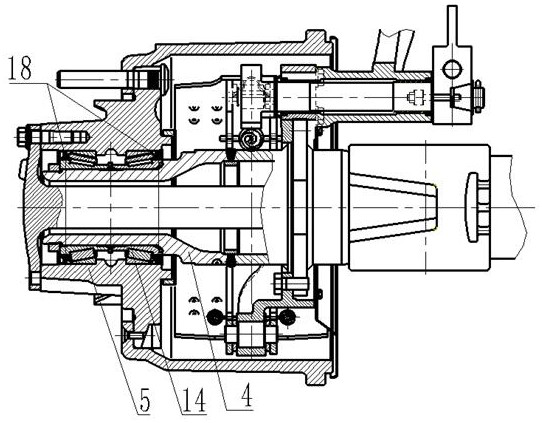

[0022] like figure 1 , 2 , 3, 4, 5, 6, a high transmission efficiency heavy truck drive axle structure assembly, consisting of input shaft assembly 1, main cone shaft assembly 2, differential shaft assembly 3, axle housing with reducer Shell 4, hub assembly 5, main and driven spur gear 6, main and driven bevel gear 7 and through shaft 8, the number of wheel hub assemblies 5 is 2; among them, the differential shaft assembly 3 has a differential Shell assembly 9, axle housing assembly 4 with oil hole and oil plug assembly 10, input shaft assembly 1 with input shaft bearing 11 and input shaft oil seal 16, main cone shaft assembly 2 with main shaft Taper bearing 12, differential bearing 13 on differential shaft assembly 3, hub bearing 14 and hub oil seal 18 on hub assembly 5; through shaft 8 with through shaft bearing 15 and throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com