Intelligent warehouse logistics screening, distributing, feeding and conveying device

A transmission device and warehouse technology, applied in the field of logistics, can solve the problems of reducing scanning efficiency, reducing screening efficiency, reducing feeding efficiency, etc., and achieve the effect of simplifying the scanning process, improving the screening efficiency, and improving the feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

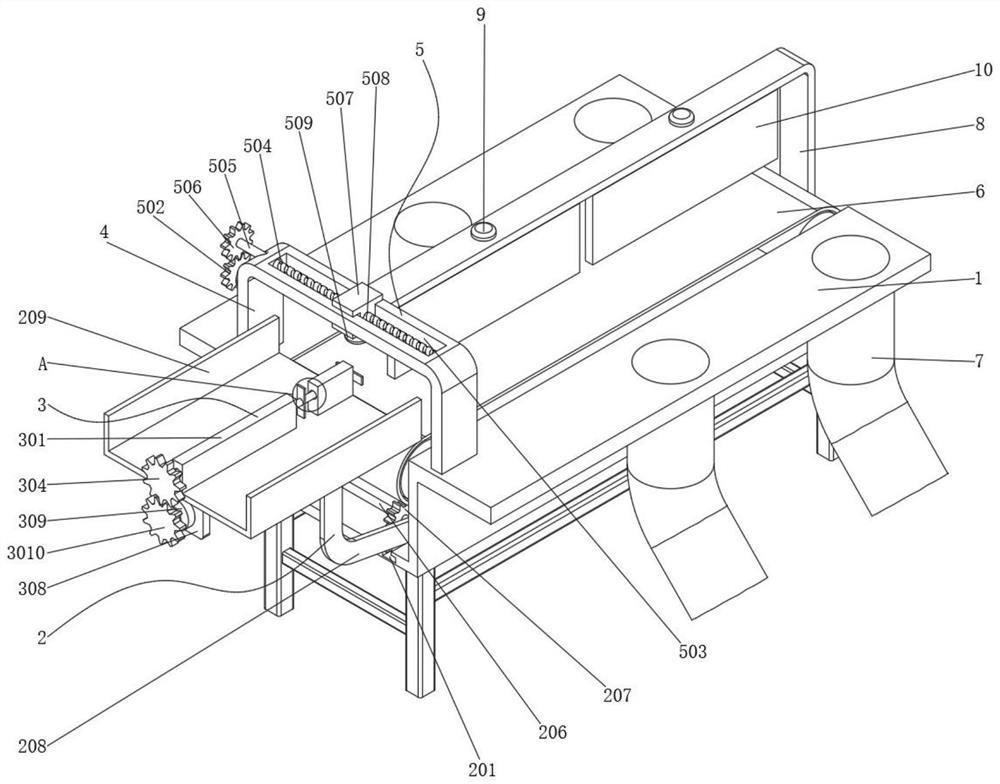

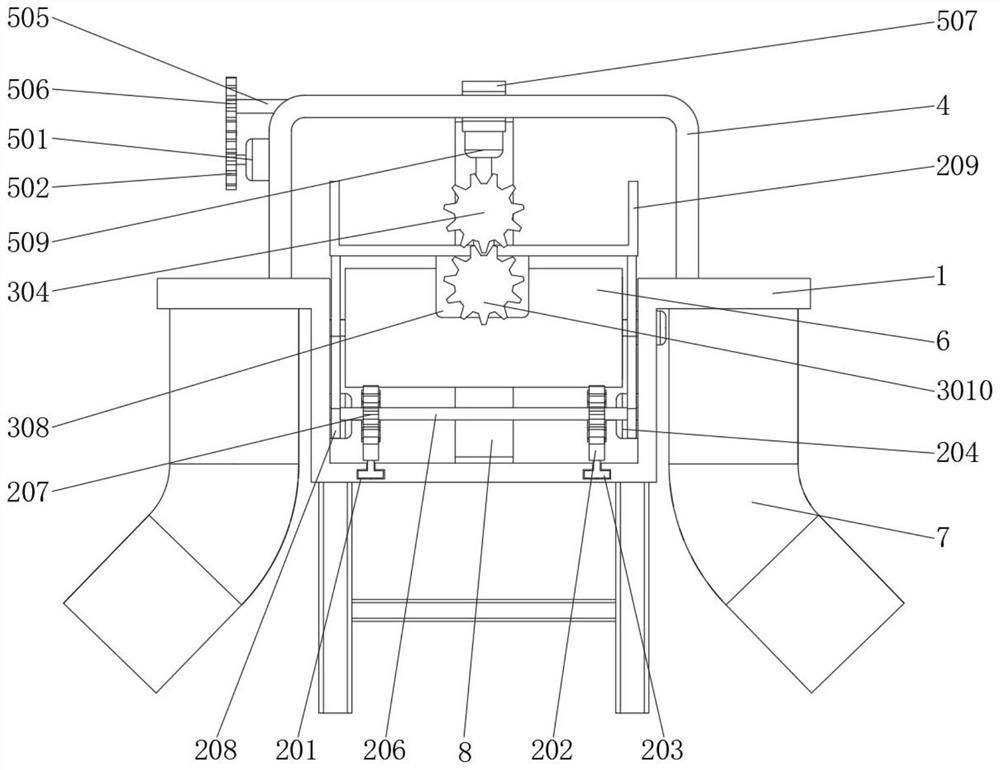

[0025] See figure 1 and image 3 , A smart warehouse logistics screening allocation and distribution of feeding transmission devices, including conveyor rack main body 1. feed component 2. Material limit component 3, first frame 4, and mobile scanning component 5, on one side of the side wall of the main body of the conveyor rack 1, there are fixed fixation on the outer wall of the main body of the main body of the conveyor frame 1. Input component 2, the material limit component 3 on the outer wall of the main body 1 of the conveyor rack main body 1, the welding on the top of the top of the conveyor rack main body 1 has the first frame 4, and the mobile scanning component on the top of the first frame 4 on the inner wall of the first frame 4 5; The conveyor mechanism 6 is installed on the inner wall of the main body 1 of the conveyor rack, which allows the first object to slip to the conveyor 6 to facilitate the transportation of the object and improve the conveying effect. There ...

Embodiment 2

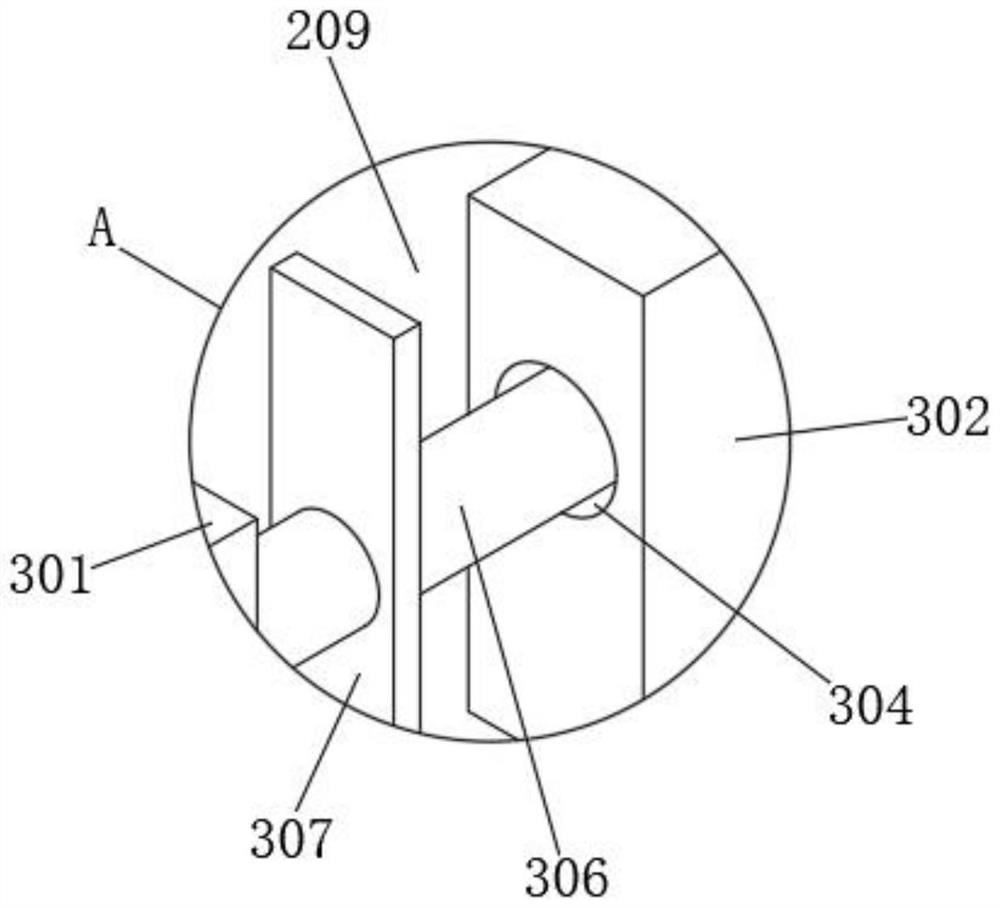

[0029] See figure 2 and Figure 4, Material Limited Components 3 include the first isolation board 301, the second isolation board 302, the first rotor 303, the third gear 304, the second rotor 305, the first limit baffle 306, the second limit baffle 307 307 , Vertical board 308, third motor 309, and fourth gear 3010, the welding of the top wall of the feed board 209 has the first isolation board 301, the feed board 209 is located on the inner wall on the inner wall of the first isolated board. The outer wall of the first isolation board 301 is installed with a third gear 304 on the outer wall of the first isolation board 301. The corresponding second rotor 305 on the inner wall of the side has the first rotor 303, and the second rotor 305 is located on the outer wall between the first isolation board 301 and the second isolation board 302. The welding on the outer wall of the one end of the turning axis 305 has a second limit baffle 307, the bottom outer wall of the third gear 304...

Embodiment 3

[0032] See Figure 5 , Mobile scanning components 5 include the fourth motor 501, fifth gear 502, second slide 503, second rotor pores 504, thread 505, sixth gear 506, second sliding block 507, thread hole 508 and scan camera 509 On the inner wall of the first frame 4, there is a second slide 503, and the inner wall of one side of the second slide 503 is rotated on the inner wall of the thread 505, and the corresponding threaded pole 505 on the inner wall of the second slide 503 There is a sixth gear 504 with a second -rotating hole 504 and a thread 505 on the outer wall of the ends of the thread 505. The corresponding threaded pole 505 is opened with threaded holes 508, and the bottom end wall of the second slide 507 is installed with a scan camera 509, the bottom outer wall of the bottom end of the sixth gear 506 is installed with fifth gear 502, the first frame 4 On the inner wall of one side, a fourth motor 501 is installed, and the output shaft of the fourth motor 501 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com