Penetrable silicone elastomer/nano catalyst material and preparation method thereof

A nano-catalyst, silicone elastomer technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as difficult synthesis, high price, and difficulty , to achieve the effects of reducing waste pollution, reducing production costs, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The penetrating silicone elastomer-loaded nano-copper catalyst of this embodiment, each sheet includes the following raw materials in parts by mass: nano-copper powder (200.0mg, 20.0%), penetrating silicone elastomer (800.0mg, 80.0%).

[0041] The preparation method of the present embodiment comprises the following steps: first, grind the nano-copper catalyst into powder with a grinding machine such as a mortar and a ball mill, then mix the target nano-catalyst with the penetrating silicone elastomer, and mix the nano-catalyst with the The silicone polymer was thoroughly mixed, and finally the resulting mixture was extruded, polymerized in air, and then cut into particles with a diameter of 2 mm.

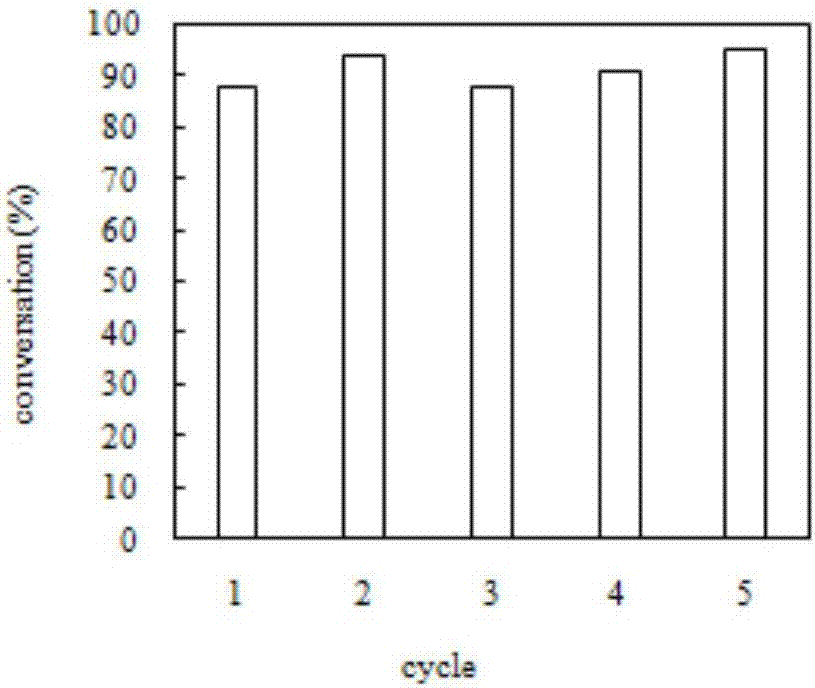

[0042] The supported nano-copper catalyst catalyzed the hydroboration reaction of alkynes and obtained 99% conversion. The cycle performance of the supported catalyst is as figure 2 shown.

[0043]

Embodiment 2

[0045] The penetrating silicone elastomer-loaded magnetic nano-copper catalyst of this embodiment includes the following raw materials in parts by mass: nano-copper catalyst (200.0 mg, 20.0%), nano-ferric iron tetroxide (100.0 mg, 10.0%) , penetrating silicone elastomer (700.0 mg, 70.0%).

[0046] The preparation method of this embodiment includes the following steps: first, grind the nano-copper catalyst into powder with a grinding machine such as a mortar and a ball mill, then mix the target nano-catalyst and nano-ferric iron tetroxide evenly, and add penetrating silicone elastomer , fully mix the nano-catalyst and the silicone polymer with a mortar, and finally extrude the obtained mixture, polymerize in the air, and then cut into particles with a diameter of 2 mm.

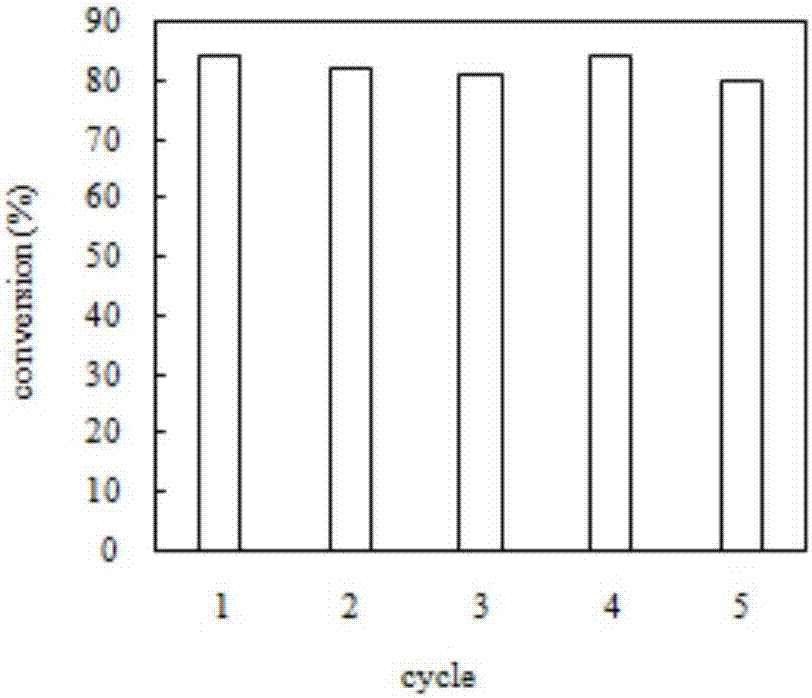

[0047] The supported magnetic nano-copper catalyst catalyzes the hydroboration reaction of alkynes, and a conversion rate of 99% is obtained. The cycle performance of the supported catalyst is as image 3 shown...

Embodiment 3

[0050] The penetrating silicone elastomer-supported palladium-carbon catalyst of the present embodiment includes the following raw materials in parts by mass: palladium-carbon catalyst (200.0mg, 20.0%), penetrating silicone elastomer (800.0mg, 80.0%) ).

[0051] The preparation method of this embodiment includes the following steps: first, grind the palladium-carbon catalyst into powder with a grinding machine such as a mortar and a ball mill, then mix the target palladium-carbon catalyst and penetrating silicone elastomer evenly, and use a mortar to grind the palladium-carbon catalyst into powder. The catalyst is thoroughly mixed with the silicone polymer, and finally the obtained mixture is extruded, polymerized in the air, and then cut into particles with a diameter of 2 mm.

[0052] The Suzuki coupling reaction was catalyzed by the supported palladium on carbon catalyst, and a conversion rate of 90% was obtained. The cycle performance of the supported catalyst is as Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com