Method for improving compaction density of lithium iron phosphate through mechanical pressurization

A lithium iron phosphate, mechanical pressurization technology, applied in chemical instruments and methods, presses, inorganic chemistry, etc., can solve problems such as unfavorable battery volume energy density, limited application, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0029] Embodiment 2 of the present invention is a method for increasing the compaction density of lithium iron phosphate by mechanical pressure. On the basis of Embodiment 1, drying in step 01 is spray drying. Spray drying has a large contact area and rapid drying, which is suitable for large-area drying of the surface of lithium iron phosphate materials.

[0030] Embodiment 3 of the present invention is a method for increasing the compaction density of lithium iron phosphate by mechanical pressure. On the basis of Embodiment 1, the protective atmosphere in step 02 is an argon atmosphere. The argon atmosphere can prevent the lithium iron phosphate from being oxidized by oxygen at high temperature.

[0031] Example 4 of the present invention is a method for increasing the compaction density of lithium iron phosphate by mechanical pressure. On the basis of Example 1, in step 02, a heating rate of 1-5°C / min is used for calcination, and calcination is performed at 700°C for 6-10 h...

Embodiment 7

[0034] Embodiment 7 of the present invention is a positive electrode material for a lithium ion battery, and the high-density lithium iron phosphate prepared by any of the methods in Examples 1 to 6 is used as the positive electrode material for the lithium ion battery.

specific Embodiment

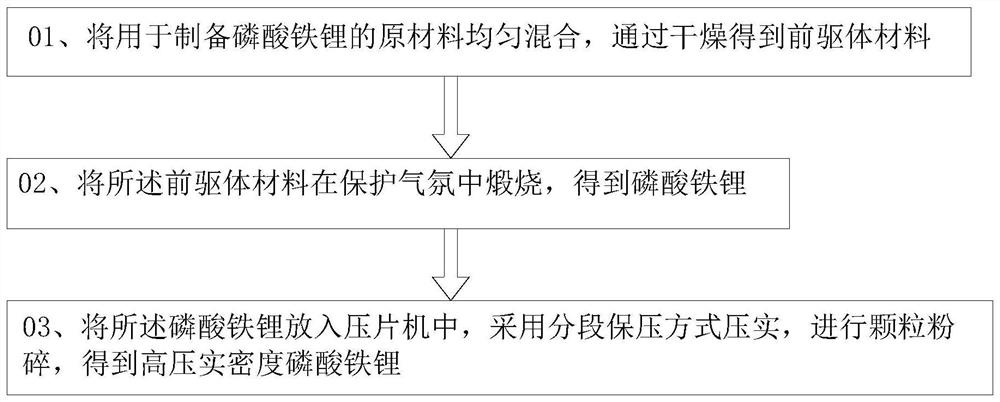

[0035] 1. The raw materials for preparing lithium iron phosphate are uniformly mixed, and the precursor material is obtained by spray drying;

[0036] 2. The precursor material is calcined at 700°C for 6-10 hours at a heating rate of 1-5°C / min in an argon atmosphere to obtain lithium iron phosphate;

[0037] 3. Put the lithium iron phosphate into the tablet press, keep the pressure every 5Mpa for 3-5min, pressurize it to 20-30Mpa, and crush the particles to obtain high-density lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com