Preparation method and production equipment of furanone

A production equipment and furanone technology are applied in the field of furanone preparation, which can solve the problems of low furanone yield and efficiency, and achieve the effects of improving purity, improving yield and efficiency, and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

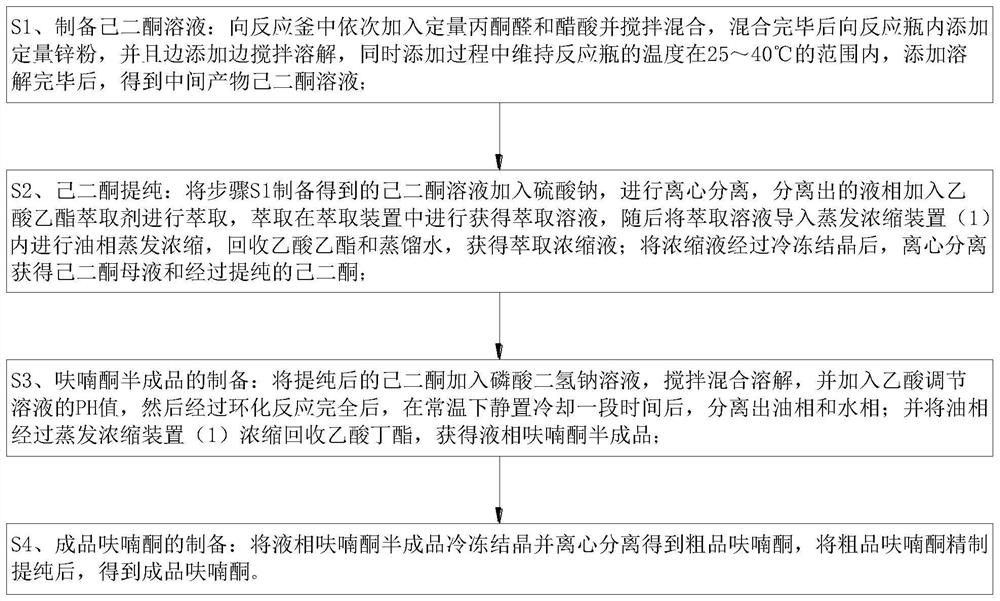

[0037] A preparation method of furanone, the preparation method comprises the following steps:

[0038] S1, prepare hexanedione solution: add quantitative glyoxal and acetic acid to the reaction kettle in turn and stir and mix, add quantitative zinc powder to the reaction flask after mixing, and stir and dissolve while adding, while maintaining the reaction flask during the addition process. The temperature is in the range of 25 to 40 ° C, and after the addition and dissolution are completed, the intermediate product hexanedione solution is obtained;

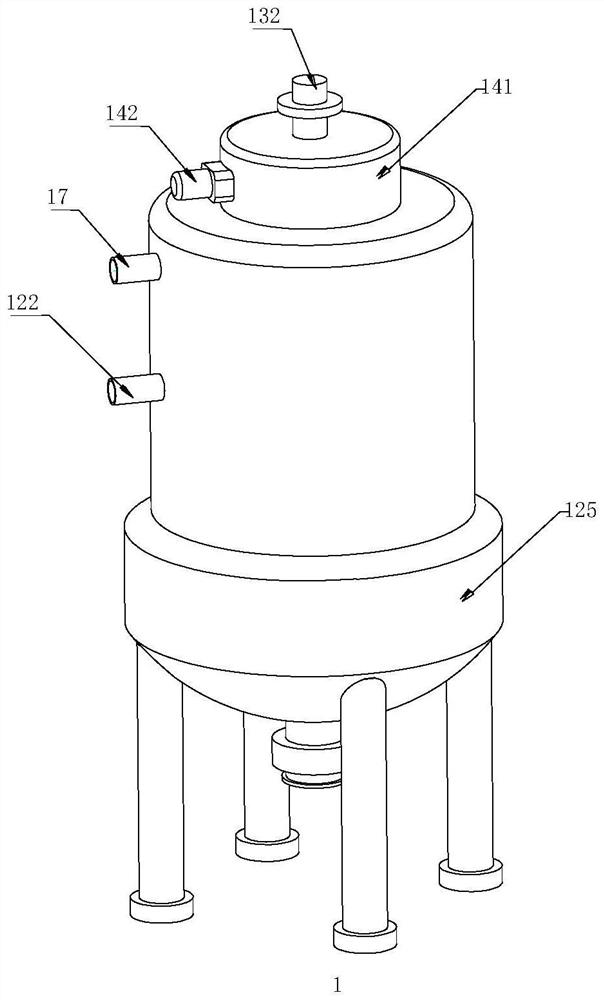

[0039] S2, hexanedione purification: adding sodium sulfate to the hexanedione solution prepared in step S1, centrifuging, adding ethyl acetate extractant to the separated liquid phase for extraction, and extracting in an extraction device to obtain an extraction solution, followed by The extraction solution is introduced into the evaporative concentration device 1 for oil phase evaporation and concentration, and ethyl acetate an...

Embodiment 1

[0066] A preparation method of furanone, the preparation method comprises the following steps:

[0067] S1, prepare hexanedione solution: add quantitative glyoxal and acetic acid to the reaction kettle in turn and stir and mix, add quantitative zinc powder to the reaction flask after mixing, and stir and dissolve while adding, while maintaining the reaction flask during the addition process. The temperature is in the range of 30°C, after adding and dissolving, the intermediate product hexanedione solution is obtained;

[0068] And the process of adding zinc powder is as follows: after stirring and mixing glyoxal and acetic acid for 15min, add 1 / 3 amount of zinc powder and stir and mix until completely dissolved, then let stand for 8min, add 1 / 3 amount of zinc powder again and stir and mix After it is completely dissolved, let it stand for 10 minutes, and finally add the remaining 1 / 3 of the zinc powder, stir and mix until it is completely dissolved, and the temperature of the ...

Embodiment 2

[0078] This embodiment is used on the basis of Embodiment 1:

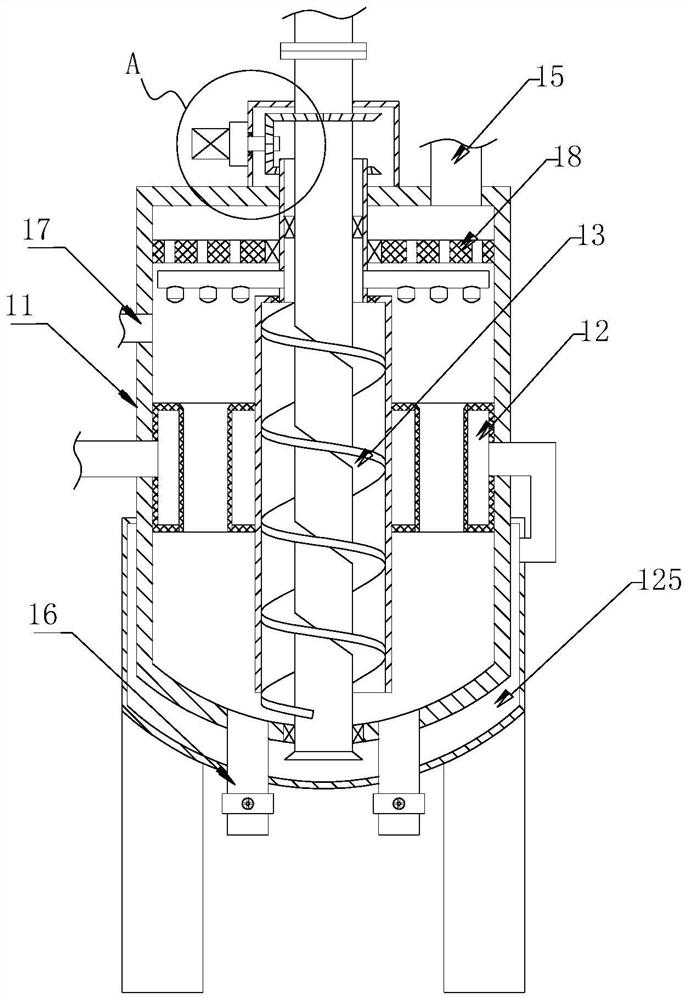

[0079] The working principle of the drive mechanism 14 is as follows: the drive motor 142 is activated, and the drive motor 142 rotates to drive the drive bevel gear 143 to rotate, thereby simultaneously driving two sets of driven bevel gears 144 to rotate, and a set of driven bevel gears 144 to drive the rotating rod 132 to rotate, so as to achieve When the liquid to be evaporated is transported, another set of driven bevel gears 144 rotates to drive the connecting pipe 1341 and the liquid spray pipe 1342 to rotate, so that the liquid spray pipe 1342 and the liquid spray head 1343 can rotate 360 degrees to achieve a large-scale and uniform liquid spray. Make the distribution of evaporating liquid more uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com