High-molecular copolymer dispersing agent for water-based paint and preparation method of high-molecular copolymer dispersing agent

A high molecular copolymer, water-based coating technology, applied in the direction of coating, etc., can solve the problems of weak steric hindrance and repulsion, reduce the hydrophilic effect of dispersant, uneven length of hydrophilic chain, etc., and achieve fast and excellent viscosity reduction. Adsorption and fixation sites, simple and easy-to-operate production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

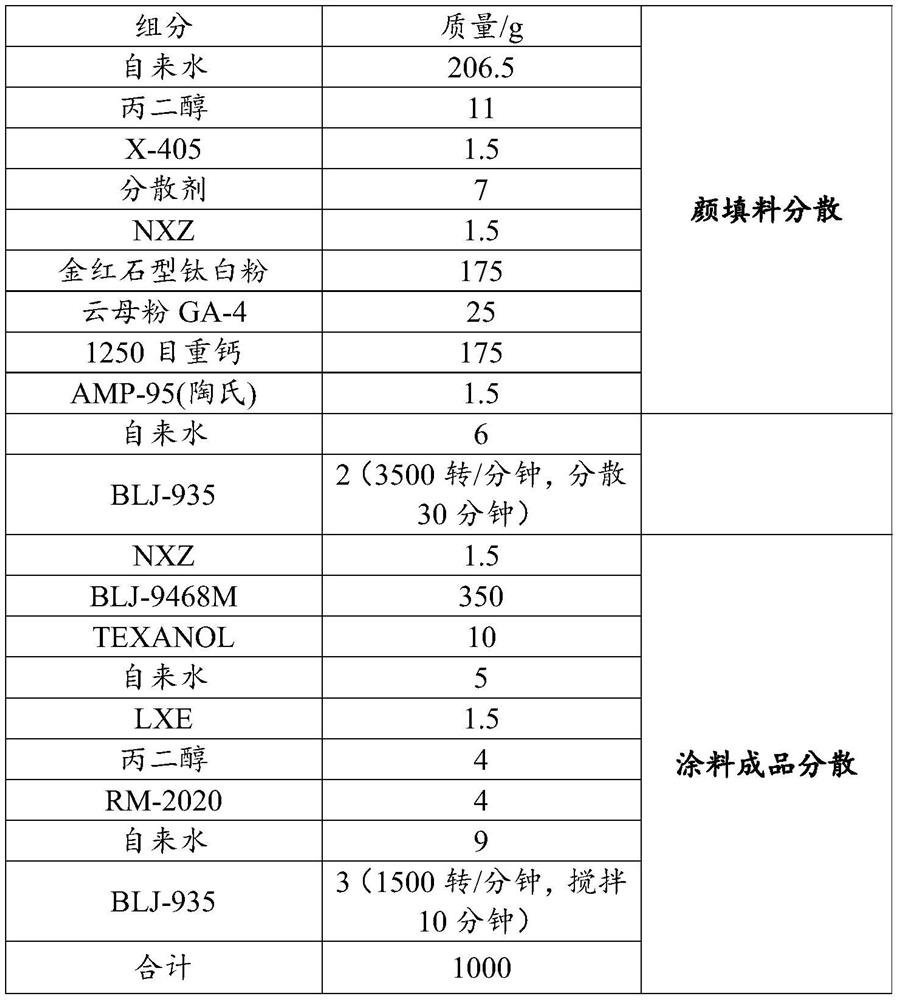

Examples

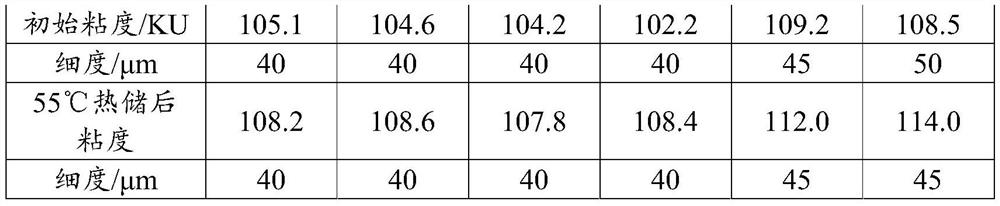

Embodiment 1

[0048] Example 1 The first aspect of the embodiment provides a hydraulic co -parts polymer dispersing agent. The raw materials include the following weights: 23.4 copies of acrylic, 1.3 copies of methyl acrocylite, 1.3 sodium lycrazethylene sulfonate, 1.5 parts over 1.5 parts too much Ammonium sulfate, 1.2 sodium virgins, 27.5 parts of ammonia, and 43.8 parts of deodorite water.

[0049] In this embodiment, the mass score of ammonia water is 25 %.

[0050] In this embodiment, the solid content of polymer cluster dispersers is 30 %.

[0051] The second aspect of this embodiment provides a preparation method for water -based coatings to use polymer cluster dispersing agents. The steps include the following steps: (1) Mixing acrylic and methampitorate, mixing uniformly, mixing the single body, mixing a single body mix Liquid; (2) Sulfate ammonium sulfate in 10 parts of ionic water to make dissolved liquid A; dissolve sodium sodium phosphate in 10 copies of ionic water to make dissolv...

Embodiment 2

[0053] Example 2 provides a hydraulic co -parts polymer dispersant for the first aspect. The raw materials include the following weights: 22 parts of acrylic, 0.5 parts of styrene, sodium methyl acrylic sulfate, and 0.6 ammonium sulfate. 3 sodium sodium sodium sulfate, 26 parts of ammonia, 45.4 part of ionic water.

[0054] In this embodiment, the mass score of ammonia water is 25 %.

[0055] In this embodiment, the solid content of polymer cluster dispersers is 31 %.

[0056] The second aspect of this embodiment provides a preparation method for water -based coatings to use polymer cluster dispersers. The steps include the following steps: (1) mixing acrylic and styrene, mixing uniformly, and mixing solution; 2) Solubbing ammonium sulfate in 10 parts of ionic water to make dissolved liquid A; dissolve sodium coke sulfate in 10 copies of ionic water to make dissolved solution B; (3) with condenser, thermometer, mixer, mixer The reaction bottle is added with sodium acrylic sulfate ...

Embodiment 3

[0058] Example 3 provides a hydraulic co-parts polymer dispersant for water-based coatings. The raw materials include the following weights: 20.8 copies of acrylic, 1.3 parts of methyl acrylic, 1.3 parts of acrylic acid, 2.6 parts of 2-acrylamidel- 2-methyl propyaline, 1.45 parts of ammonium sulfate, 1.35 sodium sodium phosphate, 27.5 parts of ammonia water, and 43.7 parts of ionic water.

[0059] In this embodiment, the mass score of ammonia water is 25 %.

[0060] In this embodiment, the solid content of polymer cluster dispersers is 30 %.

[0061] The second aspect of this embodiment provides a preparation method for water -based coatings for a polymer cluster dispersing agent. The steps include the following steps: (1) the acrylic, methyl acrylic, and acrylic acid, mix and mix well, and make a single order. Body mixed liquid; (2) dissolved ammonium sulfate in 10 parts of ionic water to make dissolved solution A; dissolved sodium sodium phosphate in 10 parts of ionic water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com