Polyester fiber drafting device for police clothing woven products

A polyester fiber and drafting device technology, applied in textile/flexible product manufacturing, final product manufacturing, textile and papermaking, etc., can solve problems such as hidden dangers of safe operation, tow entanglement, fiber broken wires, etc., to reduce the problem of broken wires , Conducive to heat dispersion, reliable effect of fiber heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

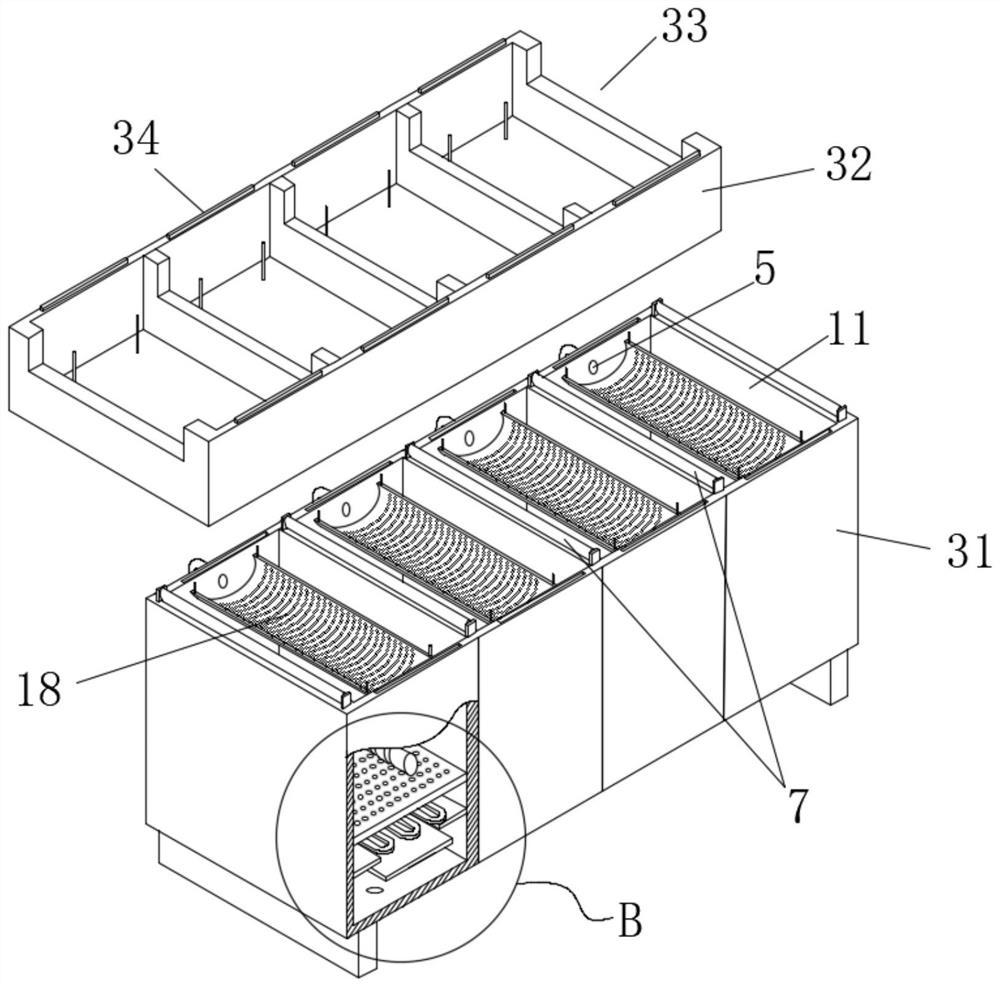

[0035] see attached figure 1 , this embodiment provides a polyester fiber drafting device for police clothing woven products, including a traction unit 1 and a water bath unit 2, the traction unit 1 is divided into a front side traction roller group and a rear side traction roller group, both of which have the same structure , including the upper roller group 13 and the lower roller group 14, the polyester fiber is installed in a serpentine winding manner between the upper roller group 13 and the lower roller group 14, the front side traction roller group is installed on the left mounting plate 12, the rear side The traction roller set is installed on the right mounting plate 16, the water bath unit 2 is located between the front side traction roller set and the rear side traction roller set, the water bath unit 2 includes a water bath box 3, and the water bath box 3 contains 4 groups of water bath chambers isolated from each other 11. From left to right, the temperatures of t...

Embodiment 2

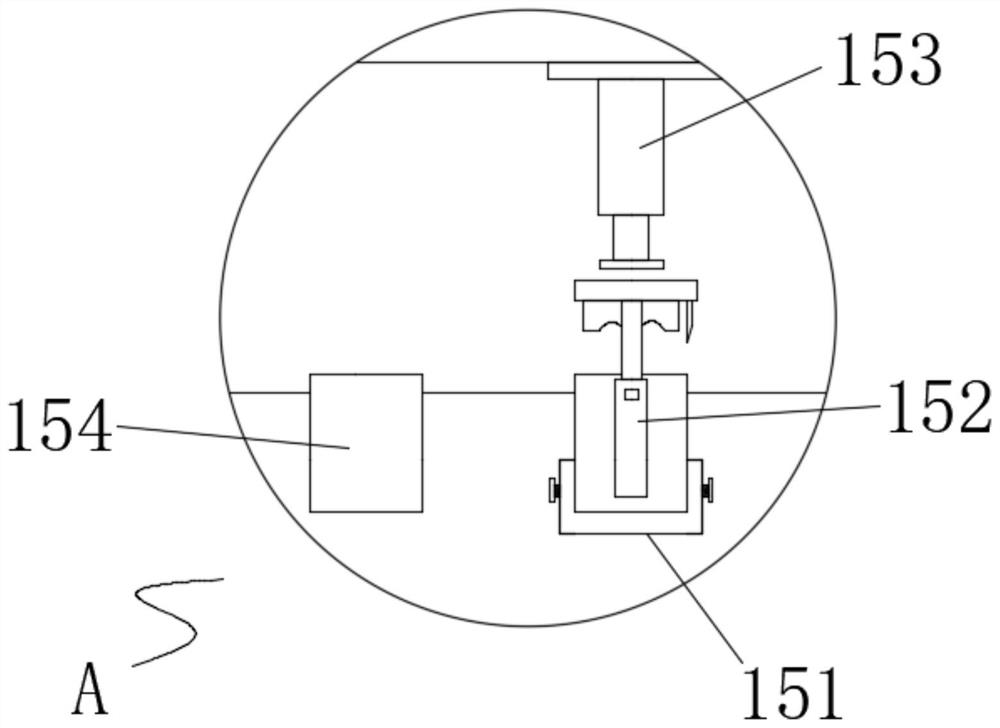

[0044] On the basis of the first embodiment, a new type of cutting unit 15 is designed in the second embodiment. The cutting unit 15 can not only cut the fiber bundle, but also press and fix the cross section of the fiber bundle after cutting. When splicing, it is only necessary to move the cutting unit 15 to drive the fiber bundles to move as a whole, which will make the splicing of the fiber bundles faster, and it is not necessary to manually splicing one by one.

[0045] For details, see attached figure 2 and attached Figure 7 , the cutting unit 15 includes a card seat 151, a self-locking pressing and cutting tool 152 and a power assembly 153. The self-locking pressing and cutting tool 152 and the card seat 151 are detachably connected before; the self-locking pressing and cutting tool 152 includes a strip plate 1521, the bottom end of the strip plate 1521 is provided with positioning blocks 1522 at equal intervals, the top of the strip plate 1521 is equally spaced with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com