Pure cotton high-color-fastness knitted shirt color strip fabric and production process thereof

A technology with high color fastness and production technology, which is applied in the direction of fabric surface trimming, textile material treatment, and mercerizing of indefinite length fabrics. , to achieve stable color, comfortable wearing and stable fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

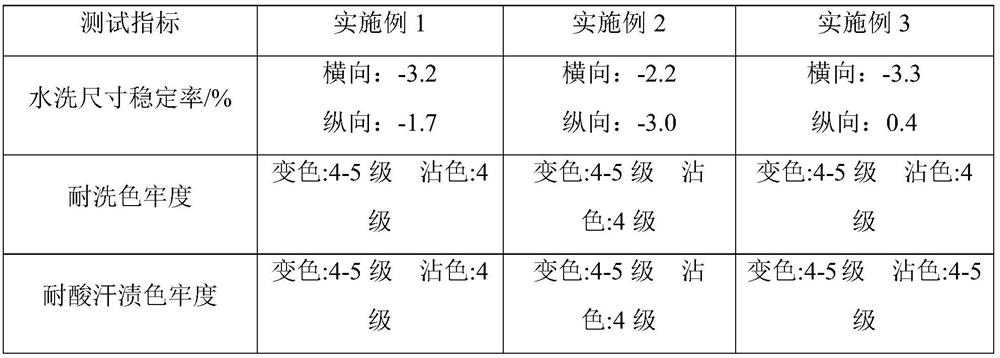

Examples

Embodiment 1

[0025] Veil 100 % fine velvet cotton Gauze 40 English branch single gauze organize Sweat color Light blue, dark blue,

[0026] The specific production process process is: before dyeing the yarn treatment → dyeing → dyeing yarn treatment → weaving → burning hair → water washing → silk light → tollment → pre -shrinkage.

[0027] Dye yarn:

[0028] Type treatment: 0.5g / L with chelating agent, 3g / L refining agent, 3.0g / L sodium hydroxide, 8.0g / L in hydrogen peroxide, 1: 10.5 bath ratio, 105 ° C for treatment, treatment time of 40min , Wash the water for 10 minutes, remove 0.2g / L in oxyase, neutralize 0.9g / L, the treatment temperature is 55 ° C, and the treatment time is 15min.

[0029] Cotton -dyeing stage: large auxiliary cylinder adds Yuanming powder, 2g / L unifferent dye agent, stirred for 15 minutes, pumped into the main cylinder to 60 ° C, insulated for 10 minutes, 1#cylinder 55 % return to water to rise to 90 ° C to 90 ° C, Klean dye Navygn (0.74 % OW...

Embodiment 2

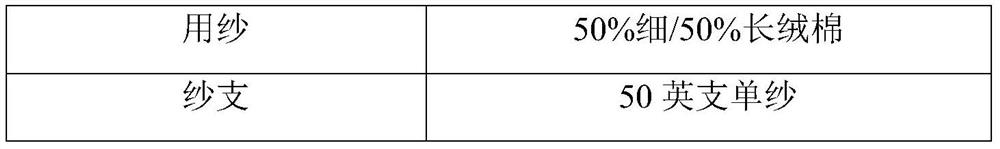

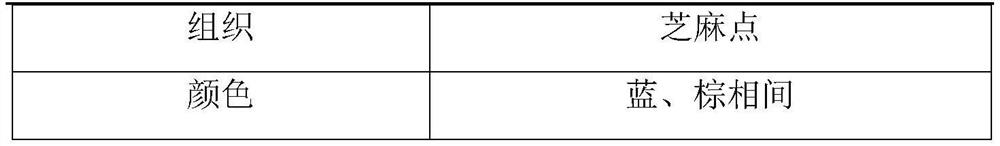

[0034]

[0035]

[0036] The specific production process process is: before dyeing the yarn treatment → dyeing → dyeing yarn treatment → weaving → burning hair → water washing → silk light → tollment → pre -shrinkage.

[0037] Dye yarn:

[0038] Type treatment: 0.5g / L with chelating agent, 3g / L refining agent, 3.0g / L sodium hydroxide, 8.0g / L in hydrogen peroxide, 1: 10.5 bath ratio, 105 ° C for treatment, treatment time of 40min , Wash the water for 10 minutes, remove 0.2g / L in oxyase, neutralize 0.9g / L, the treatment temperature is 55 ° C, and the treatment time is 15min.

[0039] During the dyeing stage: the large vice cylinder is added to the Yuanming powder, the dyeing agent (2g / L), stirred for 15 minutes, pumped into the main cylinder to rise to 60 ° C, the heat preservation was 10 minutes, and the 1#cylinder 55 % returned to 90 to 90 to 90 ℃ ℃ Klean dye Navygn (2.16 % OWF), Red6 (0.755 % OWF), Y4RN (0.27 % OWF), after stirring for 15min, quantitative annotation of 20min;...

Embodiment 3

[0044] Veil 50 % thin / 50 % long pill Gauze 60 English branch single gauze organize Bloom color White, dark and blue

[0045] The specific production process process is: before dyeing the yarn treatment → dyeing → dyeing yarn treatment → weaving → burning hair → water washing → silk light → tollment → pre -shrinkage.

[0046] Dye yarn:

[0047] Type treatment: 0.5g / L with chelating agent, 3g / L refining agent, 3.0g / L sodium hydroxide, 8.0g / L in hydrogen peroxide, 1: 10.5 bath ratio, 105 ° C for treatment, treatment time of 40min , Wash the water for 10 minutes, remove 0.2g / L in oxyase, neutralize 0.9g / L, the treatment temperature is 55 ° C, and the treatment time is 15min.

[0048] During the dyeing stage: the large vice cylinder is added to the Yuanming powder, the dyeing agent (2g / L), stirred for 15 minutes, pumped into the main cylinder to rise to 60 ° C, the heat preservation was 10 minutes, and the 1#cylinder 55 % returned to 90 to 90 to 90 ℃ ℃ Klea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com