Convection type plasma melting furnace for hazardous waste treatment

A melting furnace and plasma technology, used in incinerators, combustion types, lighting and heating equipment, etc., can solve the problems of hazardous waste dust entering, affecting the normal purification and filtration of synthesis gas, etc., to improve filtration efficiency and improve melting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

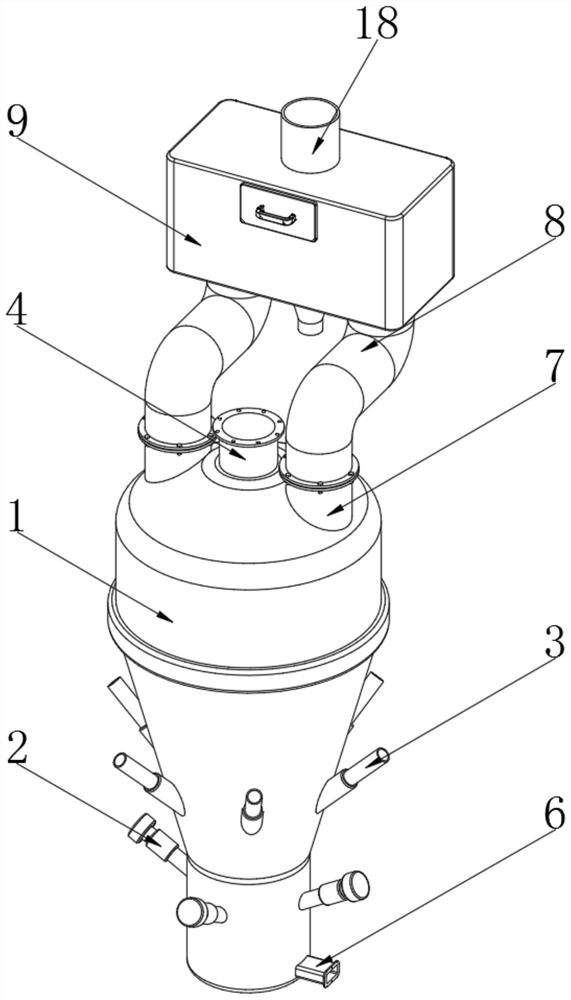

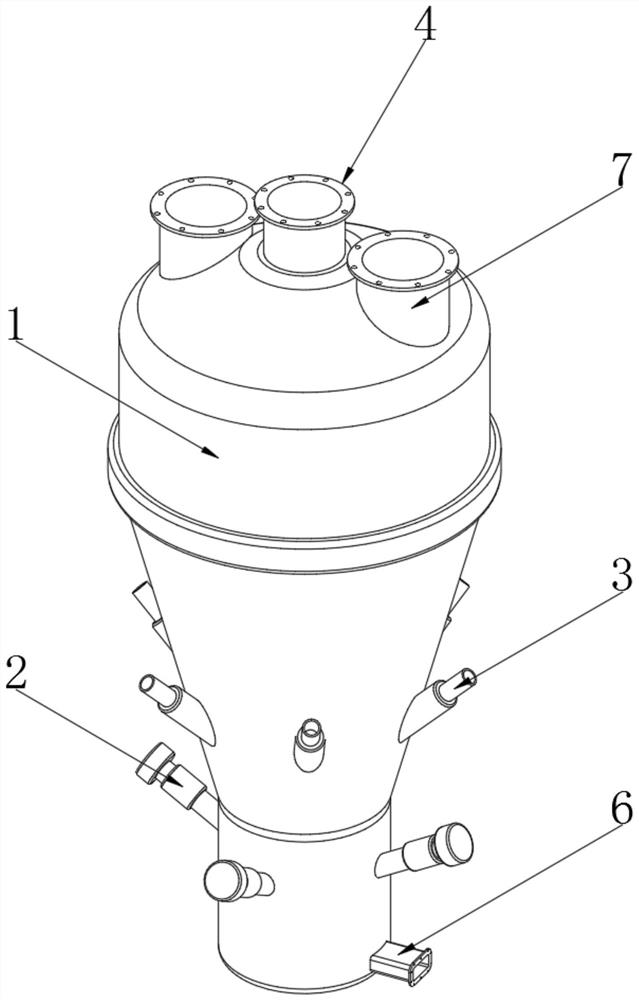

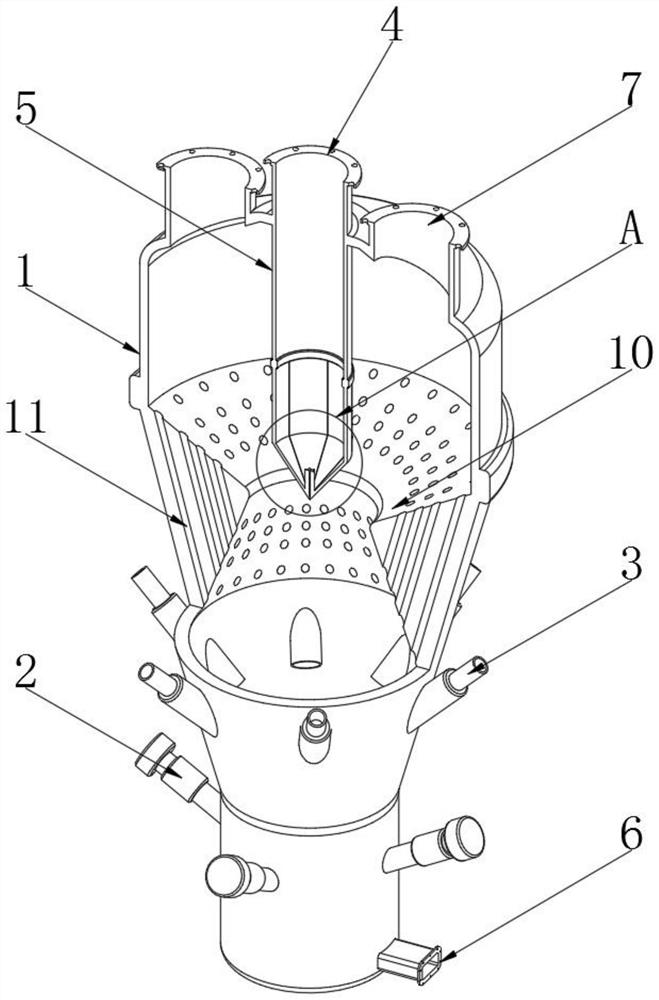

[0038] Example: such as Figure 1 ~ Figure 9 It shows that the present invention provides the following technical solutions. A type of plasma melting furnace is used for hazardous waste treatment. The ion melting furnace includes a melting furnace body 1, a plasma torch 2 at the bottom of the melting furnace body 1, and the plasma torch 2 for used for it for for used for the plasma torch. Provide the source of heat for the melting of hazardous waste, there is a wind pipeline 3 above the ion torch 2, the at the top of the melting furnace body 1 is set with inlet 4 and the synthetic gas export 7, the synthetic gas export 7 is used in the process of molting the hazardous waste melting process The small molecular gaseous substances generated are discharged, and the feed pipe 5 is set below the feed inlet 4. Venture 6 is used to discharge the vitreous furnace slag formed by the melting of the hazardous waste out of the melting furnace body 1. The synthetic gas export 7 is connected to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap