Omnibearing multi-angle optimization method based on deformation prediction

An optimization method and all-round technology, applied in the field of blade deformation optimization, can solve the problems of lack of research, complex process, lengthy calculation time, etc., and achieve the effect of improving processing efficiency, shortening processing time, and optimizing algorithm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical characteristics, purposes and effects of the invention, the specific implementation of the invention is now explained in detail.

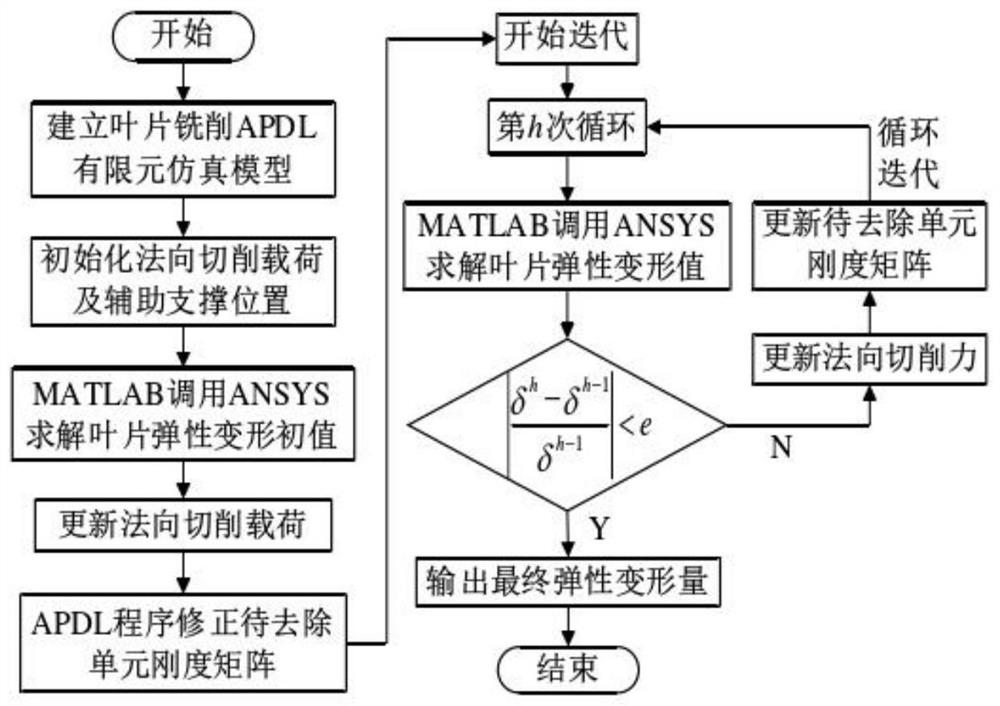

[0039] The invention provides a comprehensive multi -angle optimization method based on deformation prediction, facing the surface of the surface of the curved surface, mainly includes the following steps:

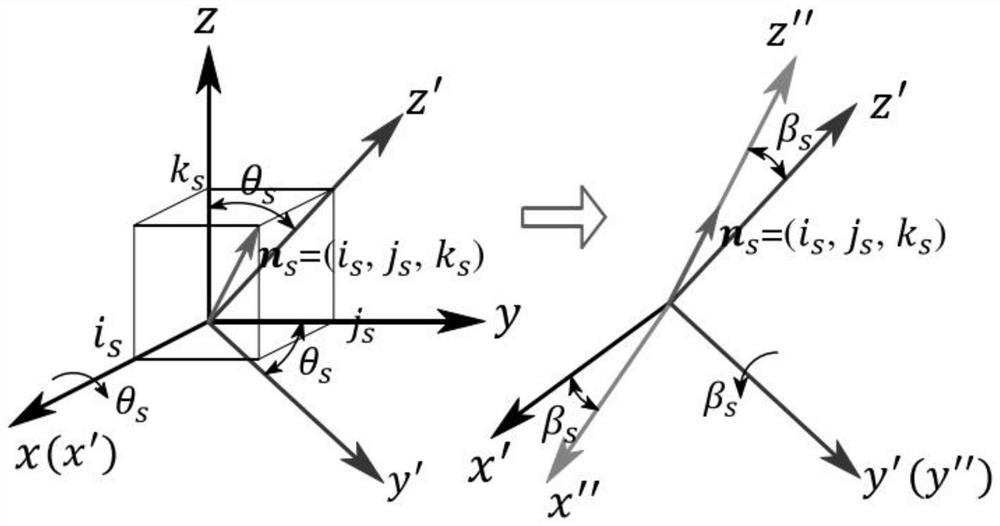

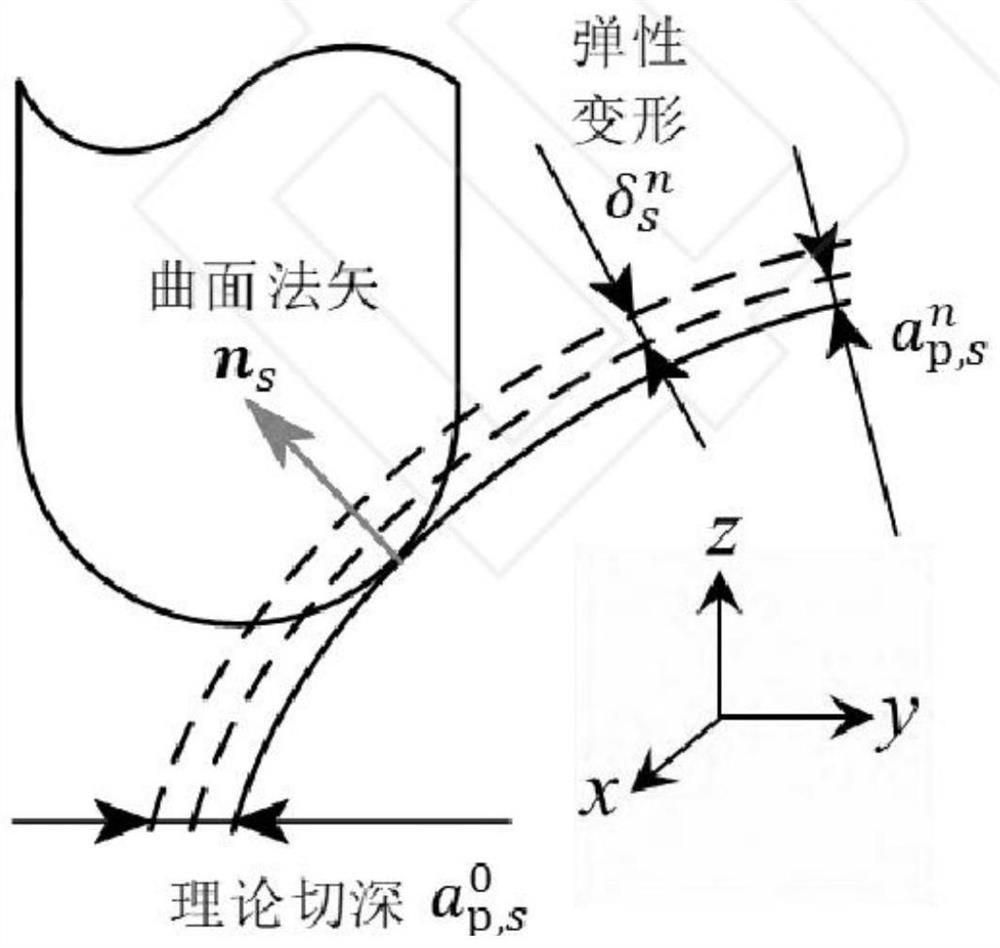

[0040] S1: Considering the material removal and milling and elastic deformation coupling effects, the leaf milling finite element simulation model is established to predict the curved surface shape;

[0041] S2: In order to reduce the curved surface shape predicted in step S1, a thin-walled blade based on GA-SVR is used as a design variable with a supporting support layout and milling cutting parameters. Evaluation indicators; use "unit life and death" technology, Latin super cubic test design, and blade milling finite element simulation model to calculate the advantages and disadvant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com