Refractory Cr-base alloy

A technology of superalloy and chemical composition, applied in the field of high temperature parts of heating furnace, can solve the problems of poor oxidation resistance, low limit height, low high temperature strength, etc., and achieve the effect of stable structure, excellent high temperature strength and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

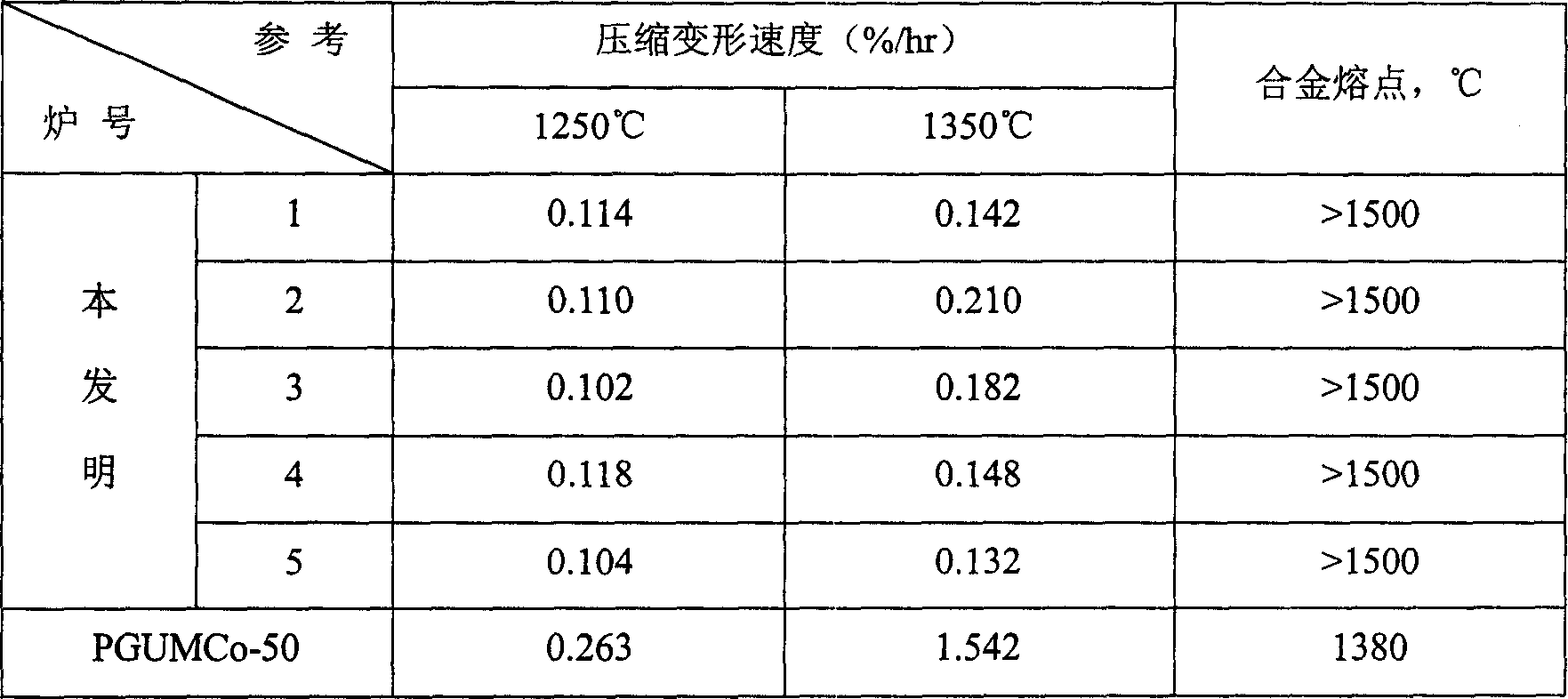

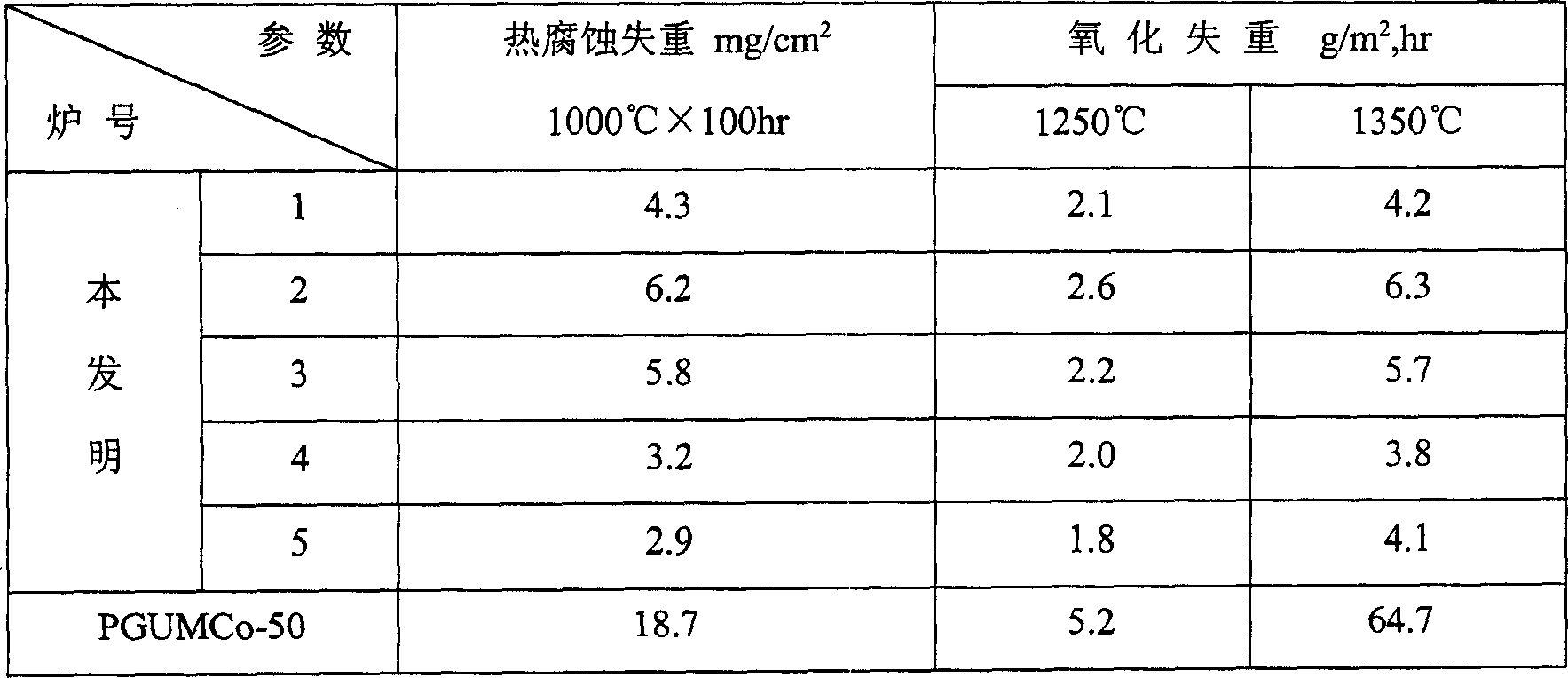

[0026] According to the chemical composition and production method of the present invention, 5 furnaces of chromium-based superalloys are smelted on an induction furnace. Its specific chemical composition is shown in Table 1. After smelting, the alloys of the 5 furnaces were all made into parts according to a specific process, and samples were taken at the same time, and the high temperature compression test, high temperature oxidation test and vulcanization test were carried out respectively. The results are listed in Table 2 and Table 3.

[0027] For comparison, a furnace of cobalt-based alloy PGUMCo-50 alloy was smelted under the same process conditions. The same test items were also carried out separately. Its chemical composition and various test results are also listed in the corresponding Table 1, Table 2 and Table 3.

[0028] The compression test is carried out on a high-temperature compression testing machine. The diameter of the sample is φ30mm, and the height is h 1 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com