Circular thermopile temperature sensor

A temperature sensor and thermopile technology, applied to thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve problems such as inconvenience and disadvantages, and achieve the effect of flexible time constant and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

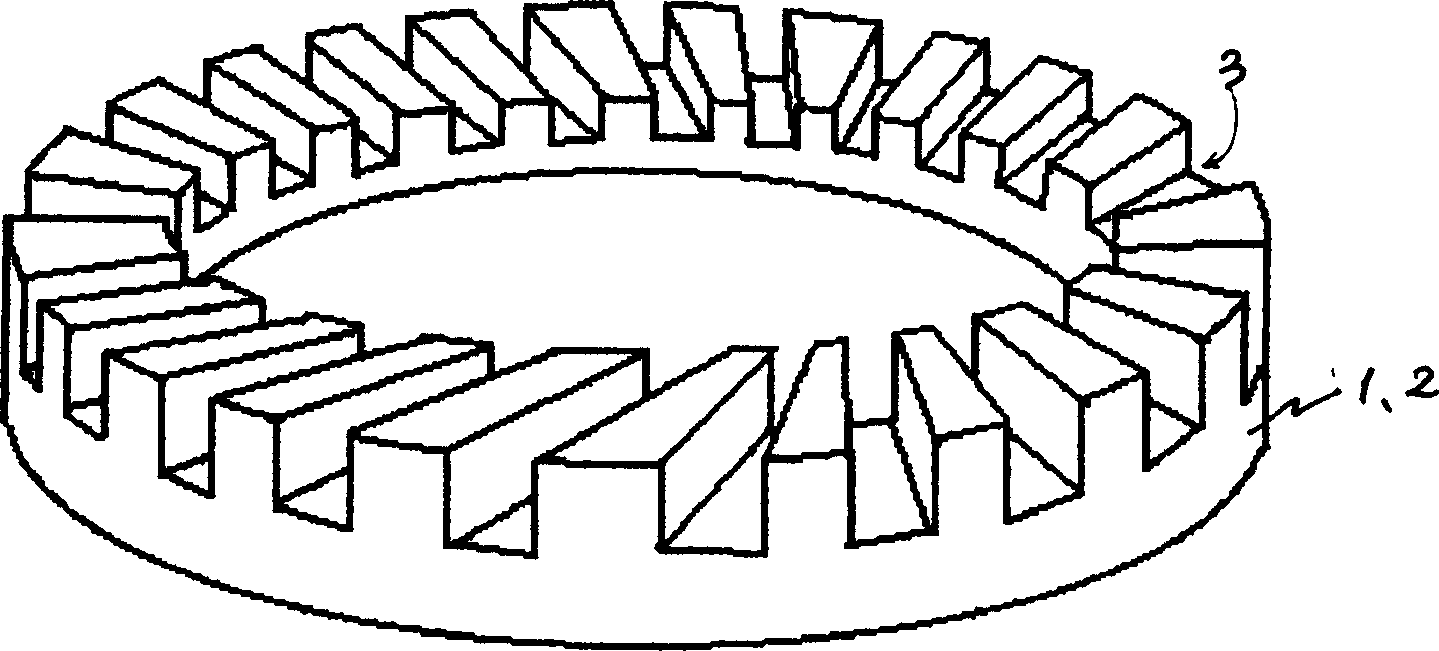

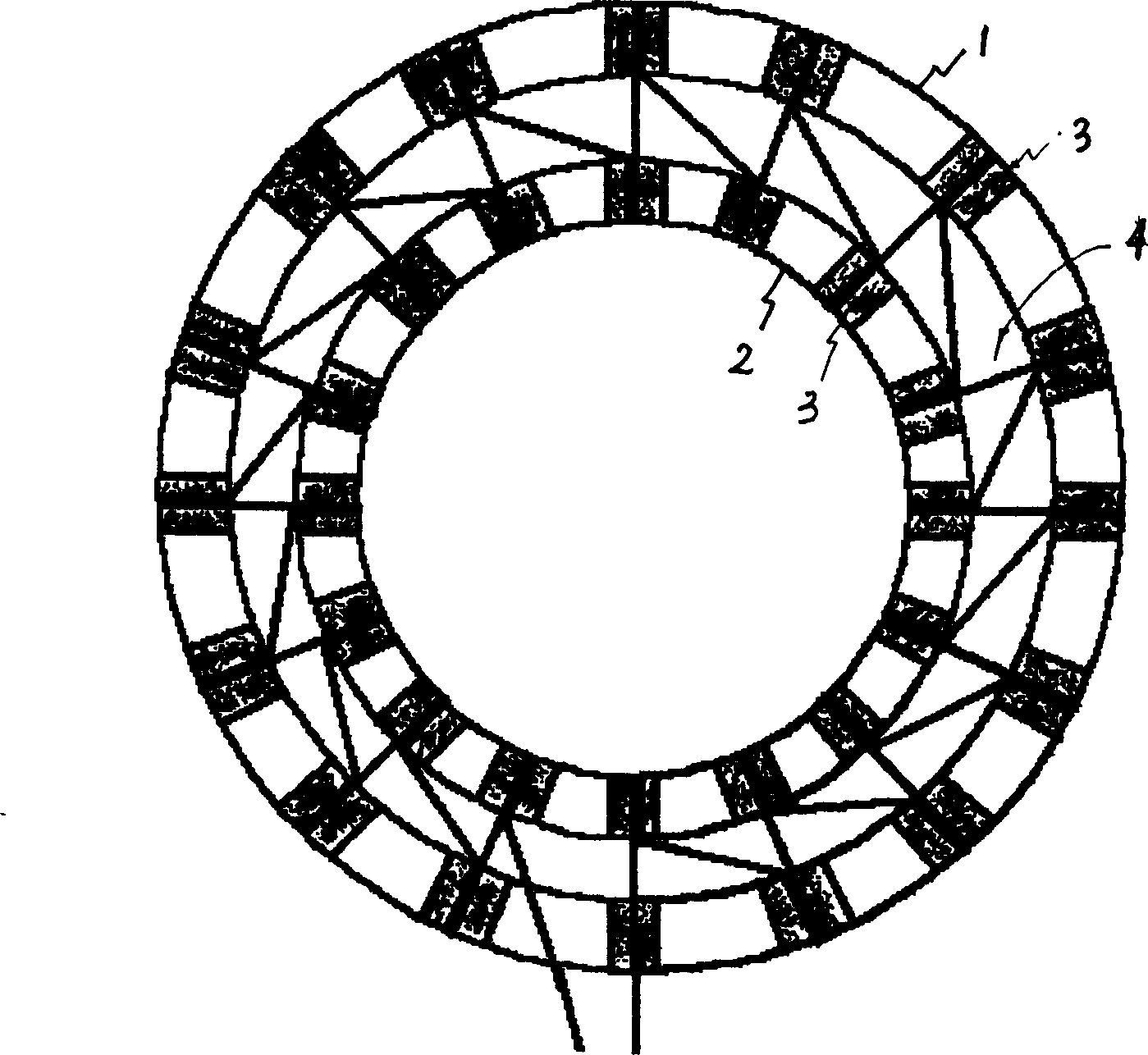

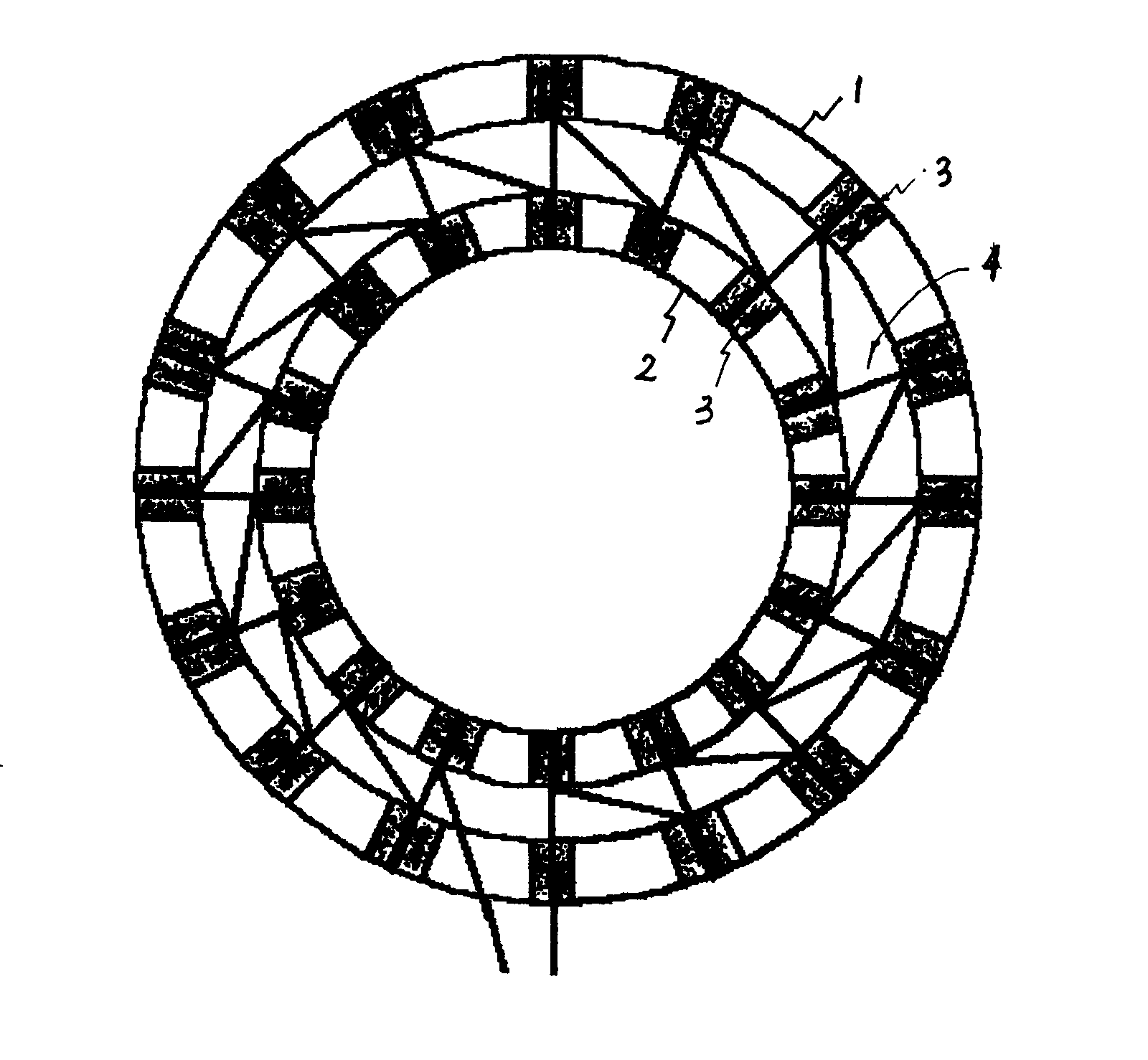

[0025] Example: There are 50 evenly distributed grooves on each of the large and small rings processed from aluminum alloy, and the large and small rings with grooves are treated with electrochemical passivation and insulation to ensure that the thermocouples are not short-circuited. The thermocouples of the annular thermopile welded by 50 pairs of nickel-chromium and constantan wires are placed in the grooves of the large and small rings, and the entire annular thermopile is fixed in the grooves of the large and small rings with epoxy resin. And set aside a head and a tail for series connection. 30 fixed large and small rings are stacked up and down in series in order to form a thermopile with 1500 pairs of nickel-chromium and constantan thermocouples.

[0026] For a thermopile stacked by 30 large and small rings, when the uppermost and lowermost two layers are placed, the thermopile is not placed in the groove, but the copper that connects the corresponding grooves of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com