Robot for cleaning alive ultrahigh voltage equipment

A live cleaning and ultra-high voltage technology, applied in the field of robotics, can solve the problems of inability to clean porcelain bottles, difficult equipment transportation, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

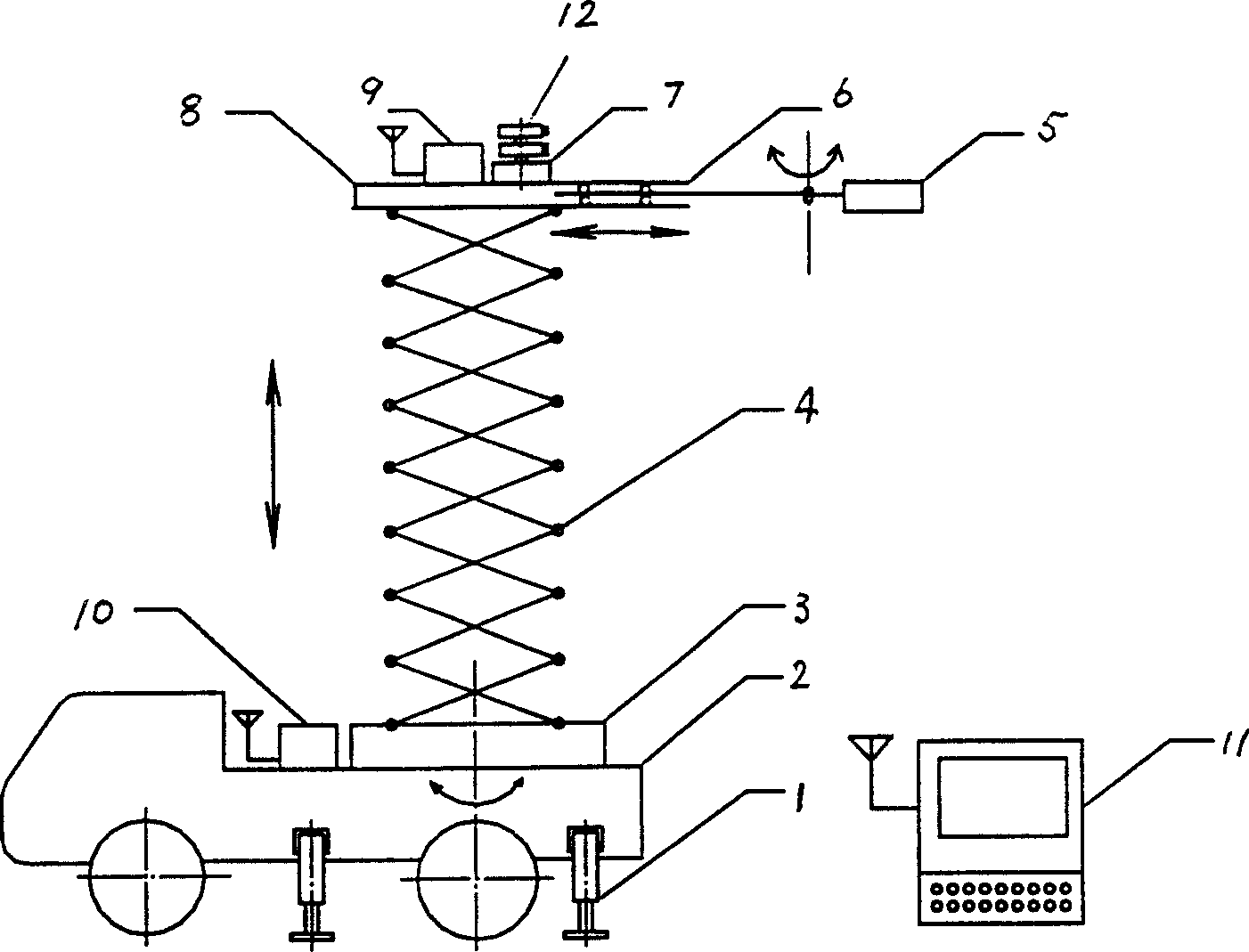

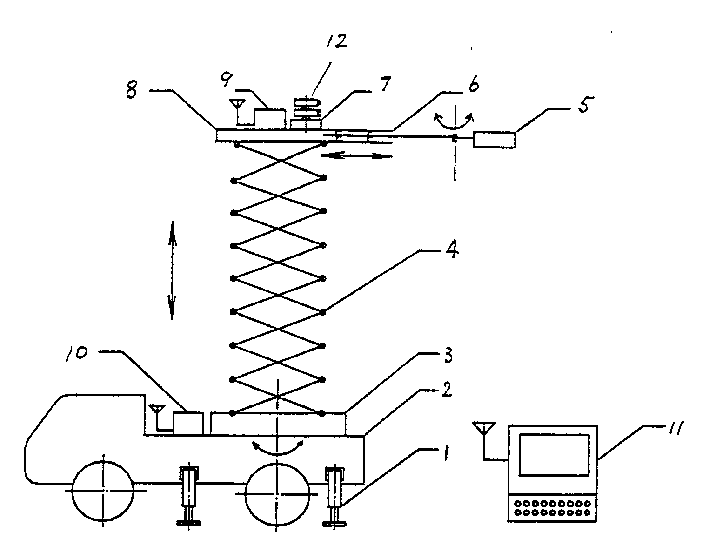

[0010] Such as figure 1 As shown, the present invention mainly includes: hydraulic automatic level adjustment system 1, mobile vehicle 2, rotary platform 3, insulated lifting mechanism 4, cleaning brush 5, cleaning arm 6, pan / tilt 7, insulation platform 8, insulation platform data acquisition system 9. The central control system 10 and the remote operation terminal 11 are connected in the following manner: the cleaning brush 5 is connected to the telescopic arm of the cleaning arm 6 through a movable joint, and the fixed part of the cleaning arm 6 and the insulating platform 8 are directly fixed to the insulating lifting mechanism 4 The vertical lifting movement is realized. The insulating lifting mechanism 4 is fixed on the rotary platform 3 to realize the +180° horizontal rotation of the sweeping arm. The rotary platform 3 is fixed on the mobile car 2, and the mobile car 2 is equipped with hydraulic automatic horizontal adjustment System 1, the rotary platform 3 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com