Preparing gamma-poly glutamic acid, glutamate, glutathione and its precursor with bacillus subtilis NX-2

A technology of Bacillus subtilis and polyglutamic acid, applied in the direction of bacteria, fermentation, etc., can solve the problems of large consumption of raw materials, long production cycle, high production cost, etc., and achieve the effect of simplifying the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Glucose 1.5%, yeast extract 0.5%, glutamic acid 3%, KH 2 PO 4 0.5%, MgSO 4 .7H 2 O0.05%, the ratio of making culture medium, the pH before sterilization is 7.0~7.5. Fill liquid 50ml in the Erlenmeyer flask of 500ml capacity, sterilize at 121 ℃ for 20 minutes, cool down.

[0037] The above-mentioned Bacillus subtilis NX-2 strain was inoculated in the culture medium, cultured at 37° C. for 24 hours, and the rotation speed of the shaker flask was 200 r / ml. The content of gamma-polyglutamic acid in the fermented liquid is 30g / l, and the productivity is 1.25g h -1 l -1 .

Embodiment 2

[0039] The medium is glucose 1.5%, yeast extract 1.0%, corn steep liquor 1.0%, MgSO 4 0.01%.K 2 HPO 4 0.01%, pH7, filling volume 50ml / 500ml Erlenmeyer flask, 120°C for 20 minutes. After the sterilization is finished, cool down and inoculate. The bacterial species is Bacillus subtilis NX-2 strain, the inoculum amount is 1%, and the shake flask is cultivated at 37° C. for 24 hours, and the rotation speed is 180 r / min. The activity of γ-glutamyl transpeptidase in the culture medium was up to 3.0U / ml.

Embodiment 3

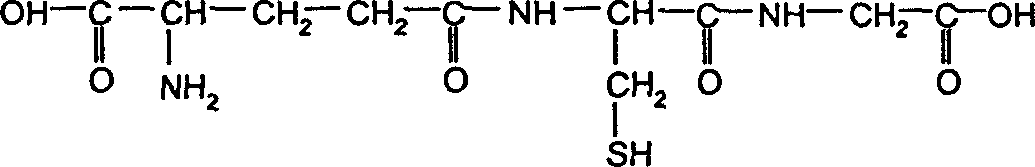

[0041] The L-cysteinyl L-glycine prepared by chemical synthesis is prepared to a concentration of 20mmol / l with 50ml of water, and then added with L-glutamic acid to make the concentration 20mmol / l, mixed as the enzyme reaction substrate, filled with N 2 stand-by. The fermentation broth obtained in Example 2 was added to the reaction substrate with an enzyme amount of 0.5 U / ml, placed in a constant temperature water bath at 37°C for 2-10 hours, and samples were taken every 30 minutes for HPLC analysis. After reacting for 10 hours, 6 mmol / l of glutathione was produced, and the conversion rate of L-cysteinyl L-glycine was 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com