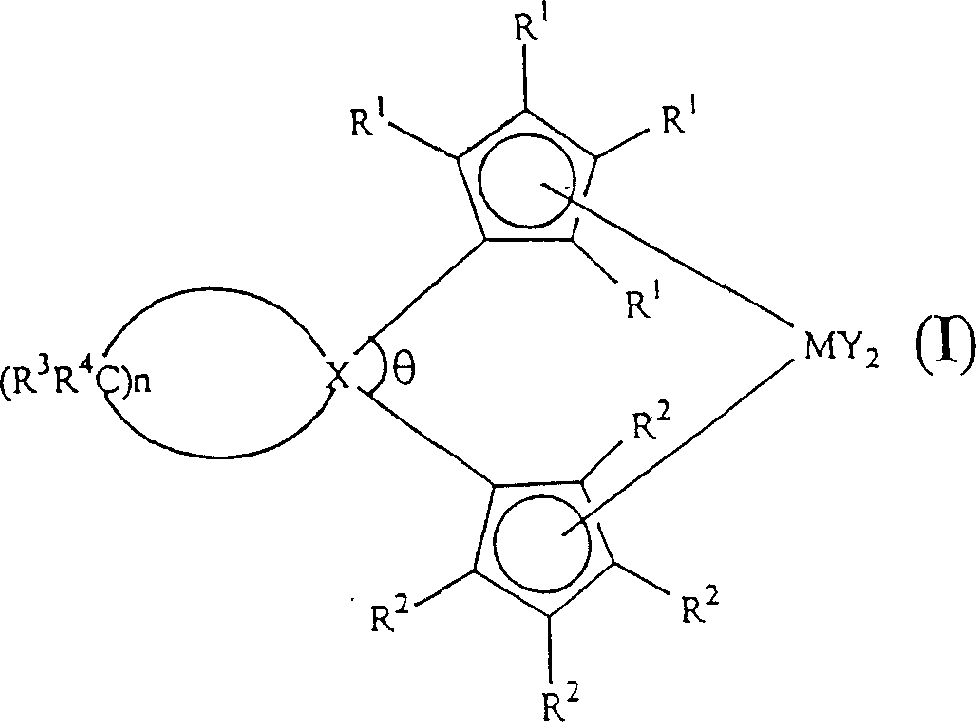

Metallocene compound for preparing olefin polymers and its use

A technology of metallocene compounds and olefin polymers, applied in the field of metallocene compounds, can solve the problems of increasing the conversion rate of cyclic olefins and ethylene, reducing the Tg of copolymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

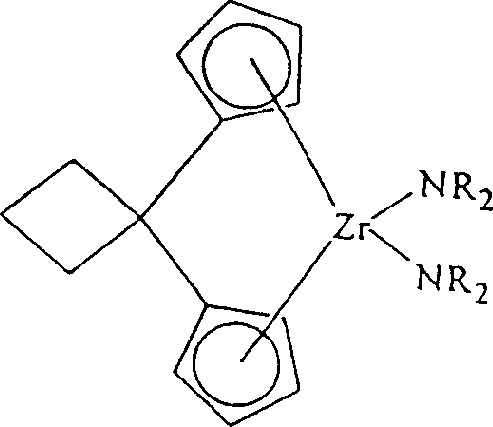

[0047] [Example 1] 1-cyclopentadienyl-1-indenyl cyclobutane

[0048] Synthesis of (1-Cyclopentadienyl-1-indenylcyclobutane) (a bridged cyclopentadiene)

[0049] Put 5.8g (50mmole) of indene into a 250ml round-bottomed flask, add 50ml of tetrahydrofuran, and slowly add 40ml (1.6M, 64mmole) of n-butyllithium under ice-bath conditions, during which the solution turns orange, and then remove the ice bath , continue to stir for 3 hours, drain all solvents, and wash out excess n-butyllithium with 50ml pentane, filter, and get the precipitate.

[0050] Add 50ml of tetrahydrofuran again to dissolve the precipitate, slowly add 5.9g (50mmole) of 6,6-trimethylenefulvene (6,6-trimethylenefulvene) under ice-bath conditions, continue to stir for 24 hours, then add 1ml of water to terminate the reaction , to drain all solvent. Then dissolve with 100ml of hexane, filter the salt, and take the filtrate. The crude product was directly separated by column chromatography using 20 g of silica g...

Embodiment 2

[0051] [Example 2] 1-methylcyclopentadienyl-1-indenylcyclobutane

[0052] Synthesis of (1-methylcyclopentadienyl-l-indenylcyclobutane).

[0053] Put 2.9g (25mmole) of indene into a 250ml round-bottomed flask, add 30ml of tetrahydrofuran, and slowly add 20ml (1.6M, 32mmole) of n-butyllithium under ice bath conditions, during which the solution turns orange, and then remove the ice bath , continue to stir for 3 hours, drain all solvents, and wash out excess n-butyllithium with 50ml pentane, filter, and get the precipitate.

[0054] Add 30ml of tetrahydrofuran again to dissolve the precipitate, and slowly add 3.3g (25mmole) of 3-methyl-6,6-trimethylenefulvene (3-methyl-6,6-trimethylenefulvene) under ice-bath conditions, and continue stirring After 24 hours, 1 ml of water was added to stop the reaction, and all solvents were drained. Then dissolve it with 50ml of hexane, filter the salt, and take the filtrate. The crude product was directly separated by column chromatography us...

Embodiment 3

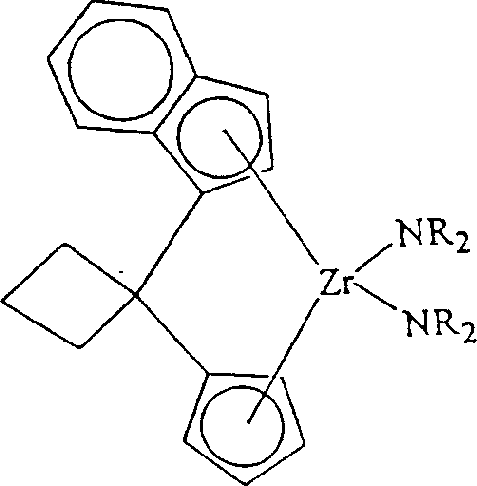

[0055] [Example 3] Cyclobutylene (1-η 5 -cyclopentadienyl)(1-η 5 -indenyl)bis(dimethylamino)zirconium ([Cyclobutylidene(1-η 5 -cyclopentadienyl)(1-η 5 Synthesis of -indenyl)bis(dimethylamino)zirconium])

[0056] Get 0.94g (4mmole) of 1-cyclopentadienyl-1-indenylcyclobutane (1-Cyclopentadienyl-1-indenylcyclobutane) and 1g (3.7mmole) tetrakis (dimethylamino) zirconium (tetrakis(dimethylamino)zirconium; (Zr(NMe 2 ) 4), put into a 100ml round bottom flask, add 20ml toluene, react at room temperature for 15 hours, then drain all solvents, add 50ml pentane again and dissolve the solid, filter, get the filtrate, and get 1.45g of yellow solid product after concentration (Yield = 95%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com