Column head and column tail structure for liquid phase chromatographic column with zero dead volume and fine inner diameter

A liquid chromatographic column and chromatographic column technology, applied in the field of column head/column tail structure, can solve problems such as column efficiency reduction and spectral band broadening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

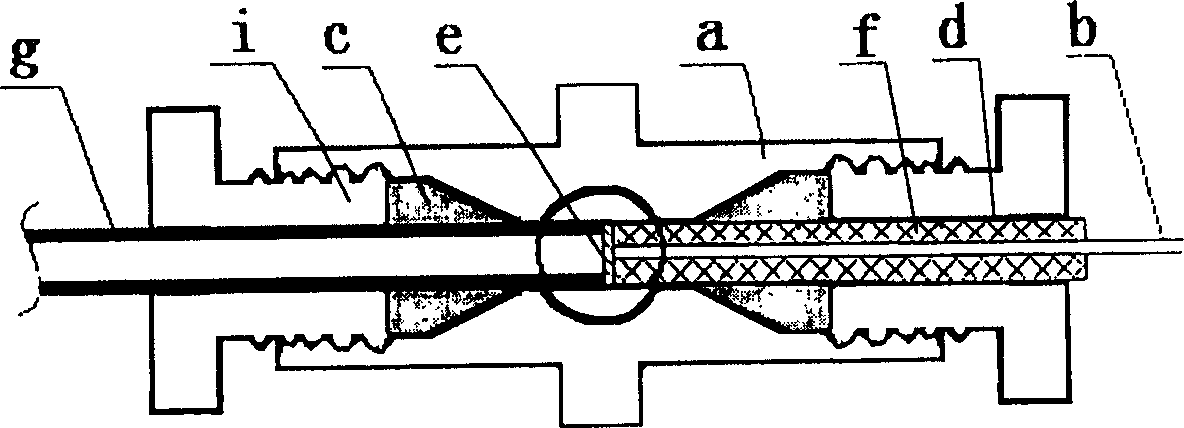

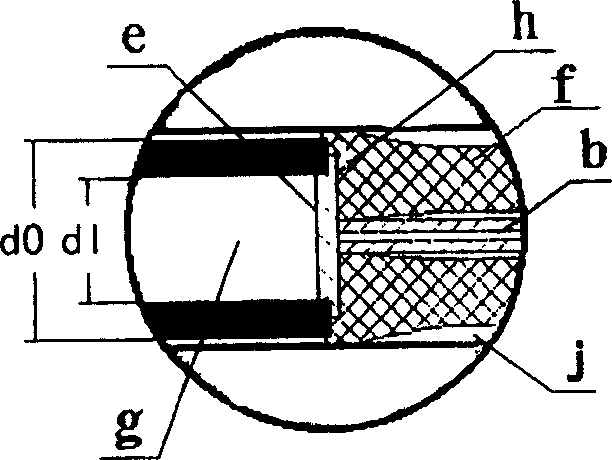

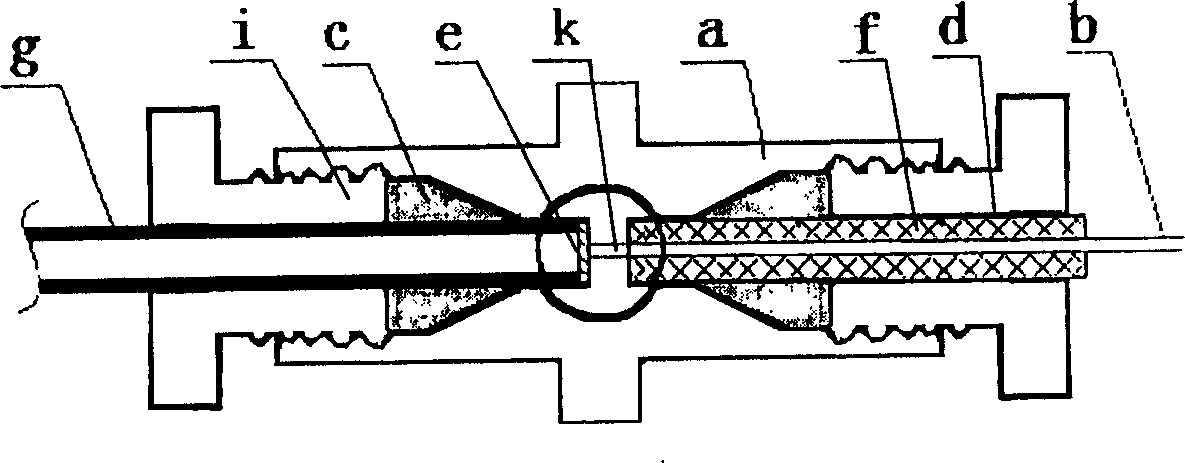

[0019] like figure 1 and figure 2 As shown, this embodiment is mainly composed of a connecting two-way a, a porous filter sheet e and an outlet pipe d, and the outlet pipe d includes a capillary tube b with a smooth inner wall and a flexible and chemically inert polytetrafluoroethylene material outside the capillary tube. The outer casing f and the chromatographic column g are stainless steel filled capillary liquid chromatographic columns, the end of which is inserted into one side of the connecting two-way a, and the other side is inserted into the outlet pipe d and the sleeve, and the two are fixed by the ferrule c and the nut i . The connecting two-way a is located between the two ferrules c, and there is an axial equal-diameter hole j. The diameter of the equal-diameter hole j is such that the chromatographic column g and the outlet tube d can be inserted in a tight fit, and the end of the chromatographic column g and the outlet tube d are placed between Porous filter...

Embodiment 2

[0021] The jacket f is made of polyetheretherketone material, the chromatographic column g is a polyetheretherketone (PEEK) filled liquid chromatographic column, the porous filter e is a stainless steel mesh filter, and the rest are the same as those in Example 1.

Embodiment 3

[0023] The jacket f is made of polyethyltrifluoroethylene material, the chromatographic column g is a stainless steel filled liquid chromatographic column, the porous filter e is a titanium alloy mesh filter, and the rest are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dissymmetry factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com