Combination electrode for the electrochemical restoration of corrosion-damaged reinforced concrete and corresponding method for controlling the same

A reinforced concrete and combined electrode technology, applied in electrochemical machining equipment, machining electrodes, electrode manufacturing, etc., can solve problems such as the inability to completely suppress chlorine, and achieve the effect of fast and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

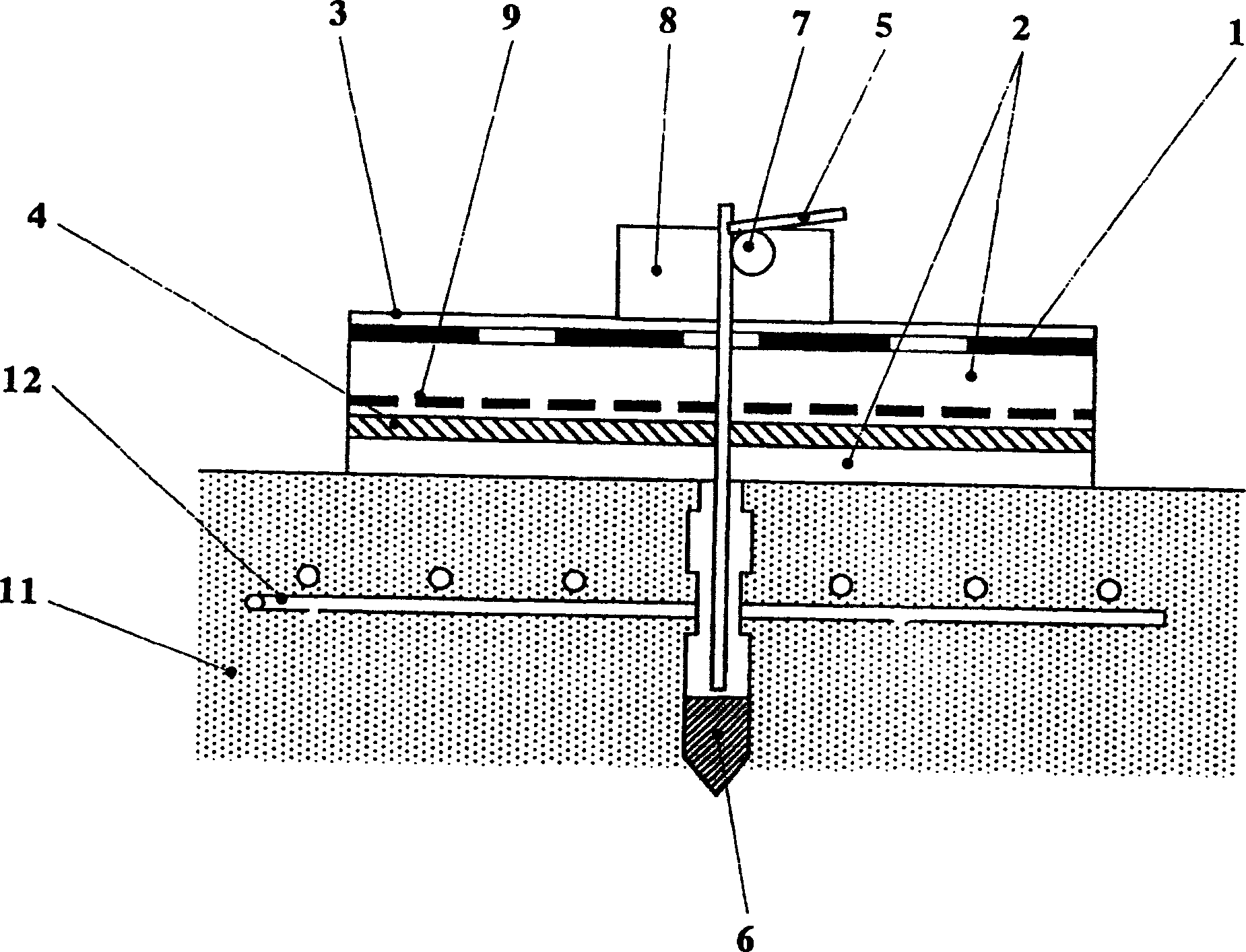

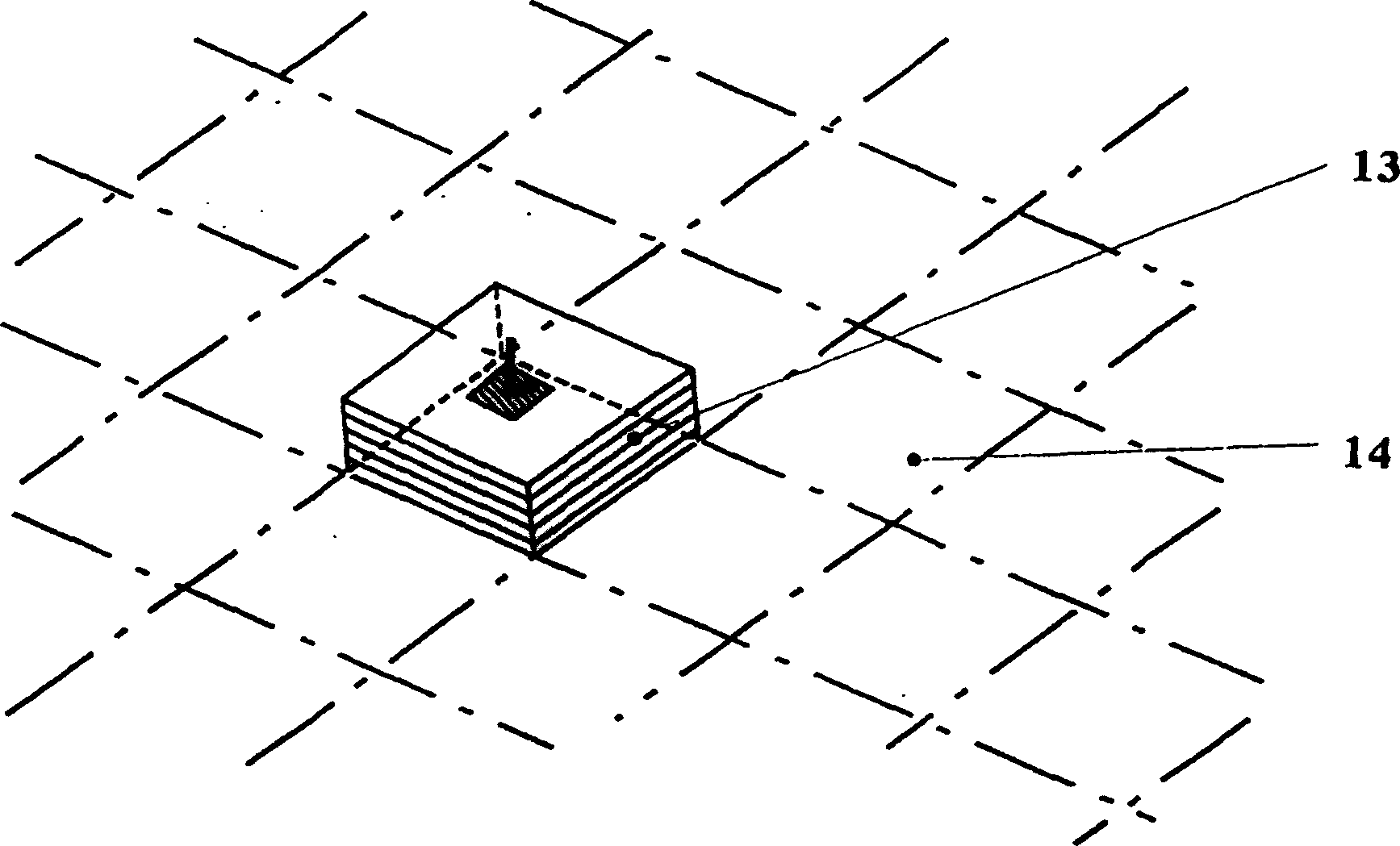

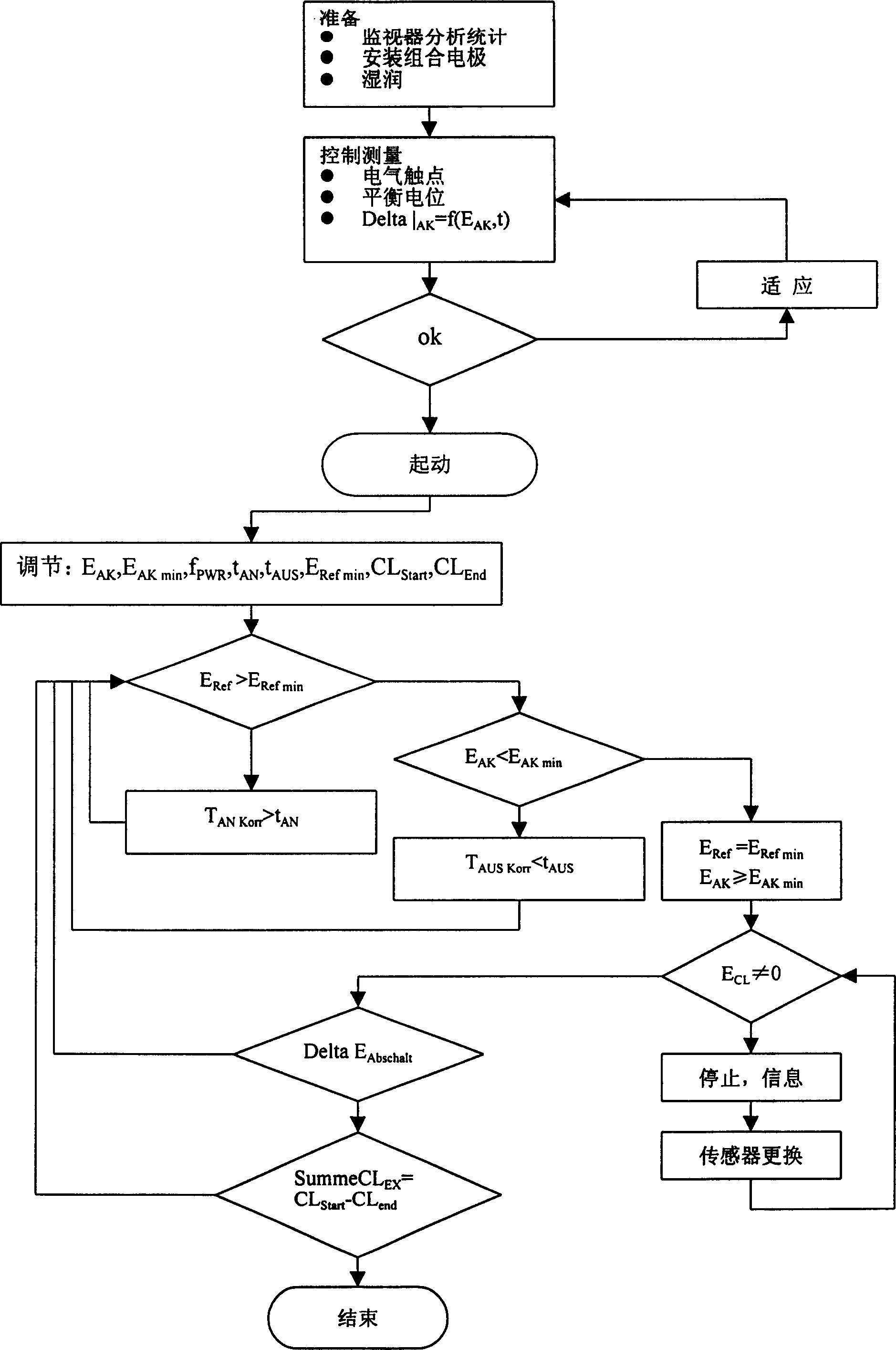

[0021] figure 1 The divided and prefabricated combined electrode is shown in Fig. 1, including a constant-dimension electrode 1; a prefabricated, reusable electrolyte reservoir 2; an evaporation cover 3 and a prefabricated, replaceable anion-exchange element 4 , which are combined with each other as a multilayer structure. A reference electrode 6 is fastened on the pin of the central fastening device 5 with pin, anchor rod and eccentric quick clamp. In addition, the composite electrode is equipped with a humidification device 7, a power switch section 8 for anode regulation, a measurement system 9 for determining the condition of the ion exchange elements and (not shown) electrical connections for the reference cell. When using combined electrodes, the pin with the reference electrode 6 enters the hole in the concrete 11 . The hole to be drilled is to be in the center of the electrode area and at the specified lateral distance from the standard steel bar 12 .

[0022] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com