A light-weight permeable concrete pavement brick and its preparation method

A technology for permeable concrete and pavement bricks, applied in the field of building materials, can solve the problems of low water permeability of foam concrete and affecting the opening rate of foam concrete bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

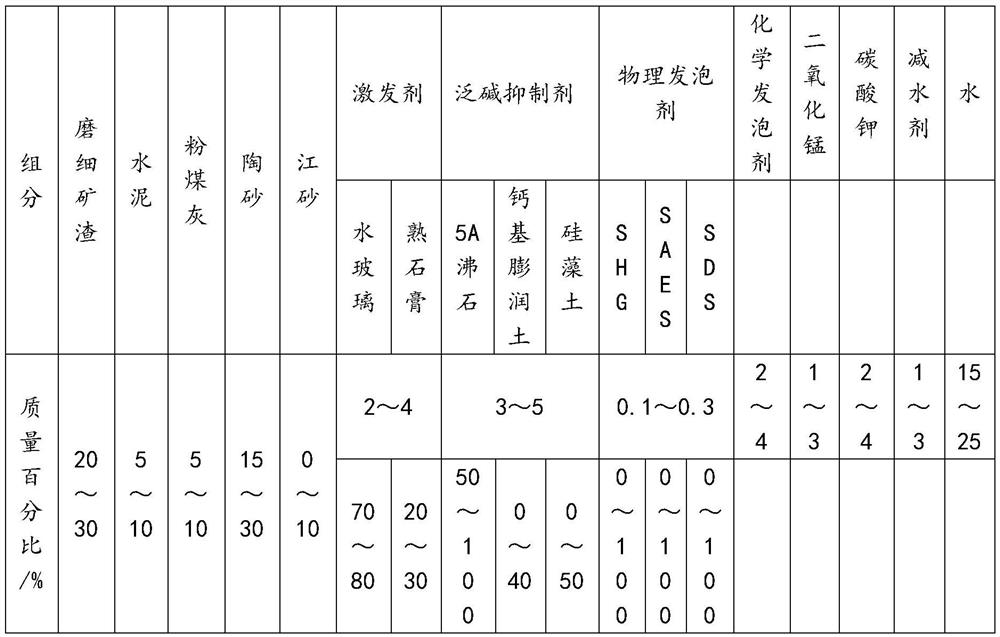

Method used

Image

Examples

Embodiment 1

[0039] In the light-weight permeable concrete pavement brick of this example, the alkaline activator is mixed with water glass (modulus 1.3) and plaster of paris in a mass ratio of 4:1, and the efflorescence inhibitor is 100% 5A zeolite. The foaming agent is 100% SHG, and the SHG powder weighed in proportion must be prepared into a foaming agent solution with a concentration of 0.3% before use.

[0040] The preparation process of the light-weight permeable concrete pedestrian pavement brick of the present embodiment is as follows:

[0041] 1) Weigh the raw materials, the mass percentage of each raw material is: ground slag 25%, cement 10%, fly ash 10%, pottery sand 15%, river sand 5%, alkaline activator 2%, pan-alkali inhibitor agent 5%, physical foaming agent 0.2%, chemical foaming agent 2%, manganese dioxide 1%, potassium carbonate 4%, water reducing agent 1%, water 19.8%.

[0042] 2) Put the ground slag, cement, fly ash, pottery sand, river sand, alkaline activator, efflor...

Embodiment 2

[0047] In the light permeable concrete pavement brick of this example, the alkaline activator is made of water glass (modulus 1.2) and plaster of paris in a mass ratio of 3:1, and the efflorescence inhibitor is made of 5A zeolite and calcium bentonite Mixed in a mass ratio of 3:2, the physical foaming agent is 100% SAES, and the SAES powder weighed in proportion must be made into a foaming agent solution with a concentration of 0.3% before use; Sand needs to be wetted to a saturated surface dry state.

[0048] The preparation process of the light-weight permeable concrete pedestrian pavement brick of the present embodiment is as follows:

[0049] 1) Weigh the raw materials, the mass percentage of each raw material is: ground slag 30%, cement 10%, fly ash 10%, pottery sand 5%, river sand 10%, alkaline activator 4%, pan-alkali inhibitor Agent 5%, physical foaming agent 0.1%, chemical foaming agent 2%, manganese dioxide 1%, potassium carbonate 2%, water reducing agent 3%, water ...

Embodiment 3

[0055] A light-weight permeable concrete pedestrian pavement brick, the alkaline activator is prepared by mixing water glass (modulus 1.2) and plaster of paris in a mass ratio of 7:3, and the pan-alkali inhibitor is composed of 5A zeolite and diatomaceous earth Mixed according to the mass ratio of 1:1, the physical foaming agent is 100% SDS, and the SDS powder weighed in proportion must be prepared into a foaming agent solution with a concentration of 0.3% before use; Sand needs to be wetted to a saturated surface dry state.

[0056] The preparation process of the light-weight permeable concrete pedestrian pavement brick of the present embodiment is as follows:

[0057] 1) Weigh the raw materials, the mass percentage of each raw material is: ground slag 25%, cement 5%, fly ash 5%, pottery sand 25%, alkaline activator 2%, pan-alkali inhibitor 3%, physical Foaming agent 0.3%, chemical foaming agent 4%, manganese dioxide 3%, potassium carbonate 4%, water reducing agent 1%, water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com