Laminated sheet material and method for making same

A manufacturing method and veneer technology, which is applied in the jointing of wooden veneers, veneer presses, manufacturing tools, etc., can solve the problem of no laminated plates, achieve the effect of suppressing warping and bending, and saving forest resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

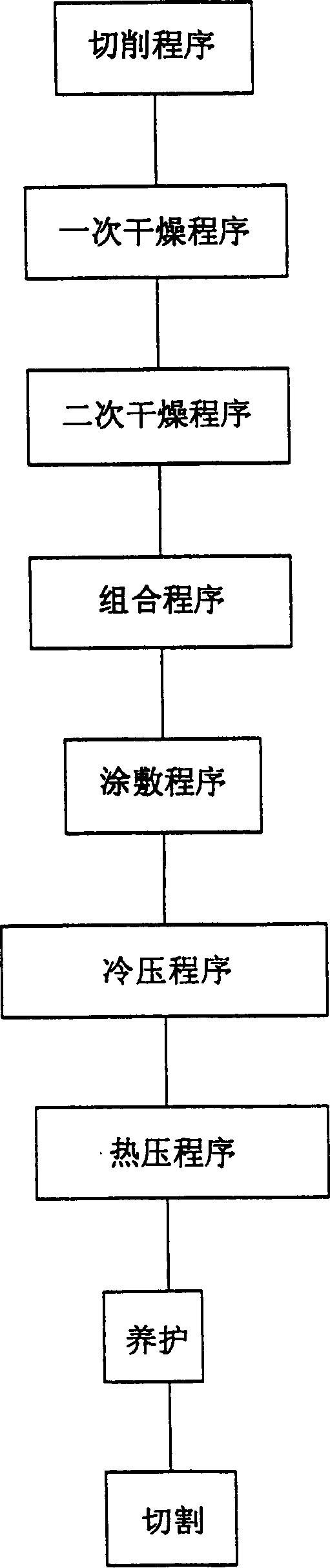

[0026] figure 1 A method of manufacturing a laminated sheet according to an embodiment of the present invention is shown. This manufacturing method uses Italian poplar logs to manufacture laminated boards, and consists of cutting process, primary drying process, secondary drying process, assembly process, coating process, cold pressing process, hot pressing process, curing, and cutting. composition.

[0027] In the cutting process, the Italian garden wood is used as a woodworking lathe, and the center of both ends of the log is supported while rotating; while it is in contact with the blade, it is peeled off from the bark side of the log one by one, and processed into a thickness of 1.8mm±0.1mm. Rectangular veneer.

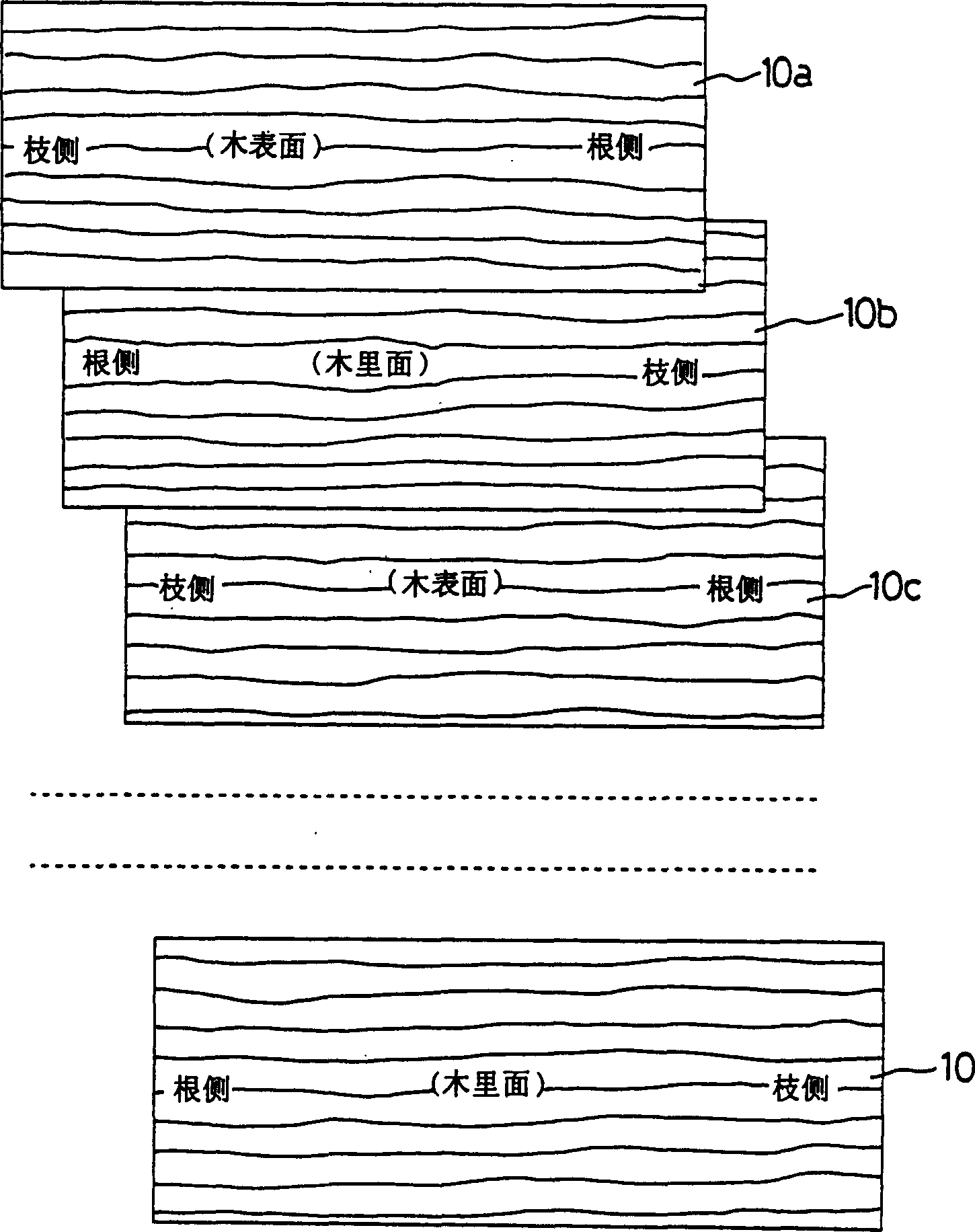

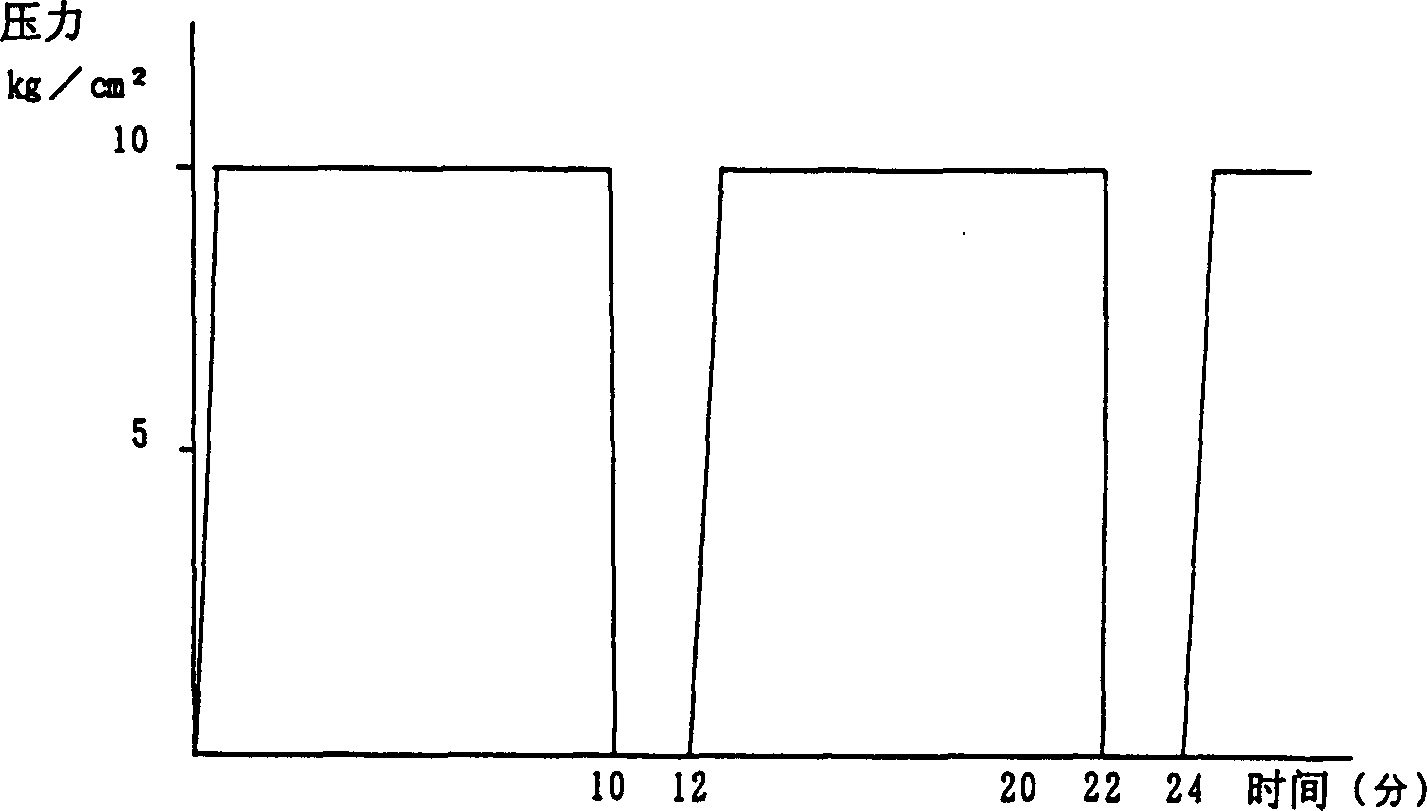

[0028] In a drying process, the rectangular veneer is sent into a drier to dry until the moisture content reaches 28%±3%, and is cut into a board at the outlet of the drier. Next, in the secondary drying process, the veneer is dried until the moisture content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com