Residential heat insulation construction, and heat insulator to be used

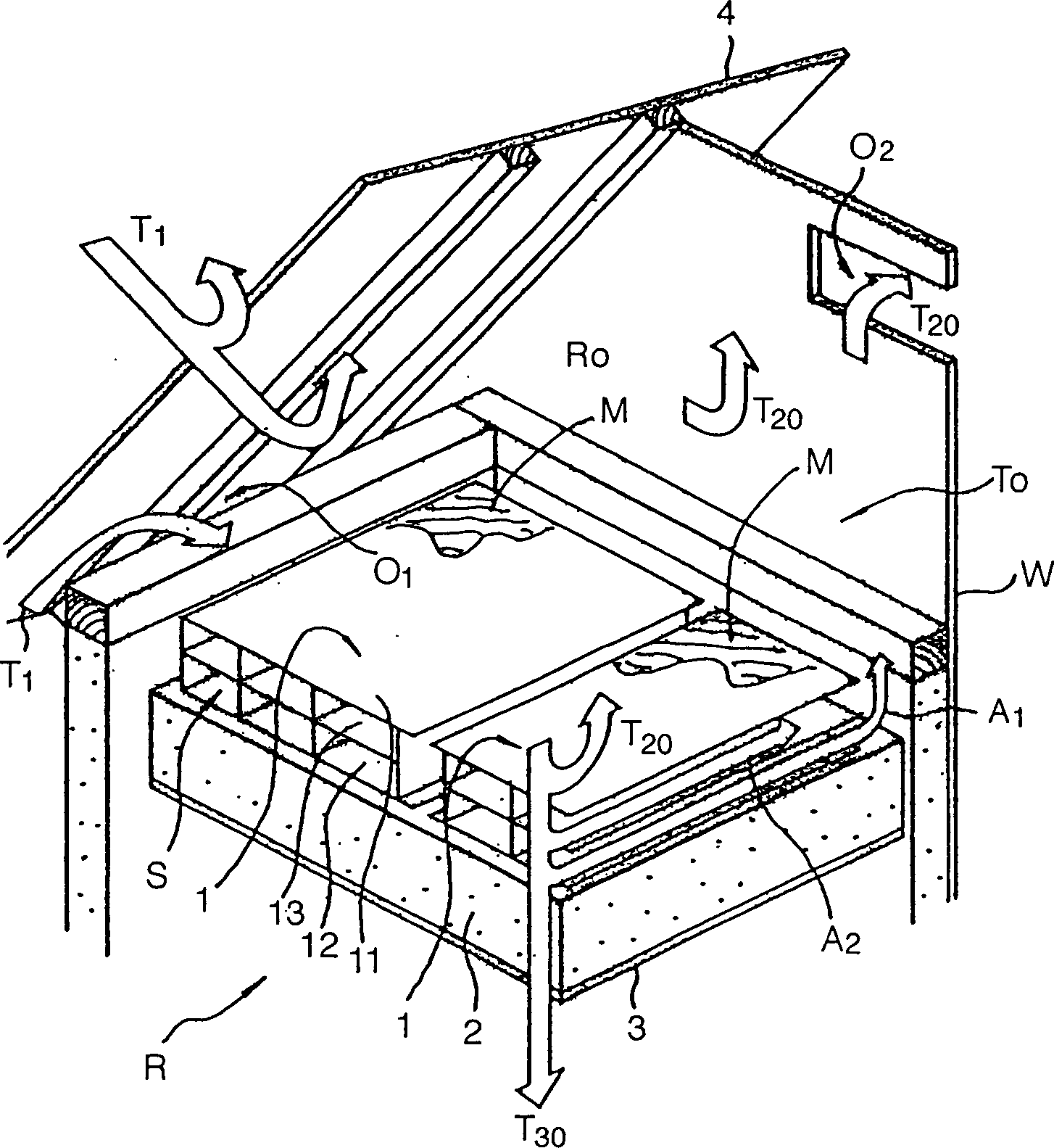

A component and housing technology, applied in the field of improvement of heat insulation structure, can solve problems such as unsuitable load of air conditioners, obstacles to maintaining comfortable environment temperature, etc., and achieve the effects of easy handling and construction, energy reduction of air-conditioning equipment, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

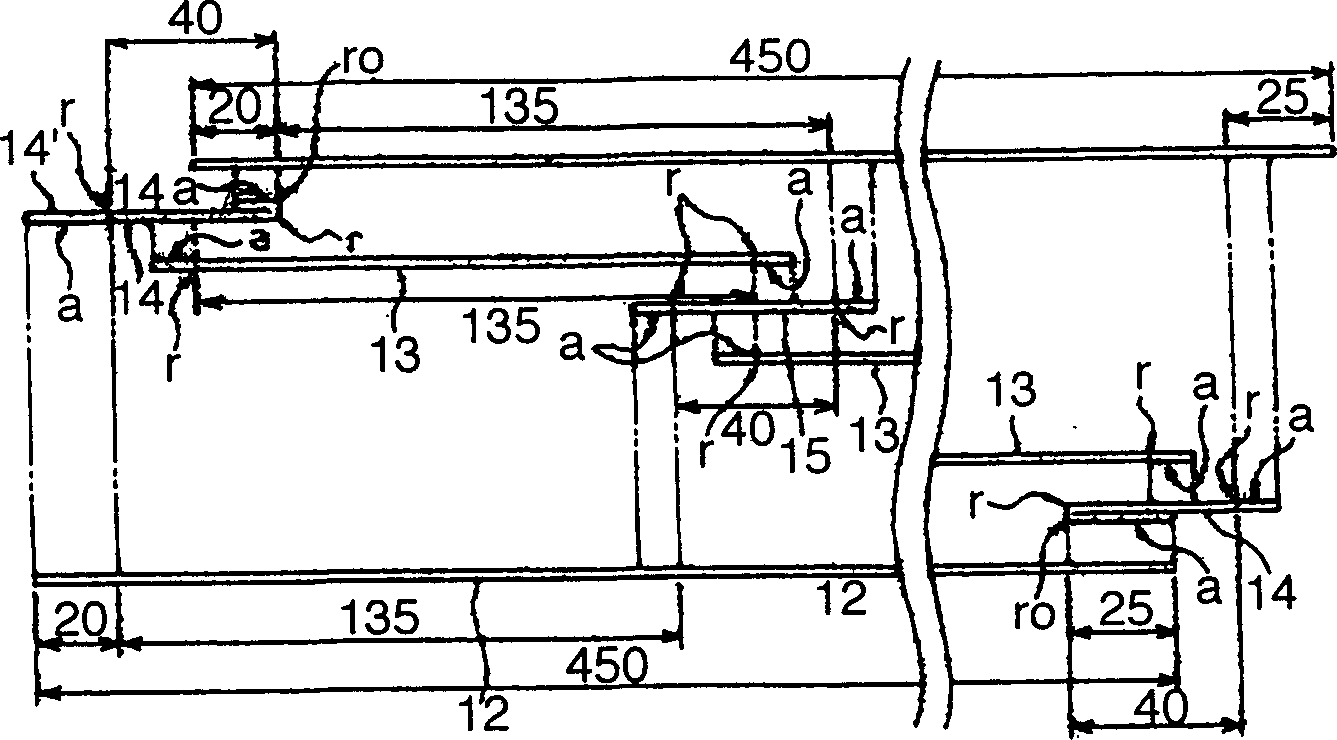

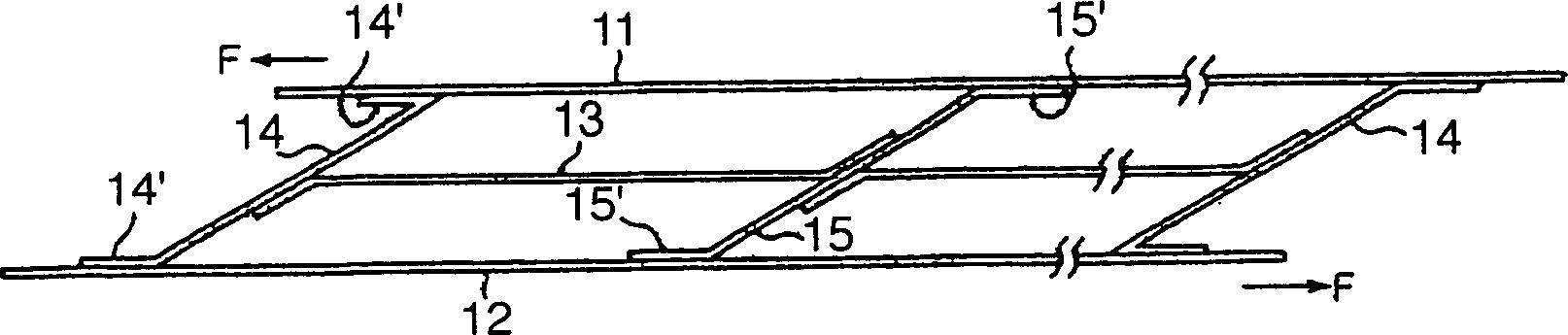

[0050] 〔Manufacture of heat shielding parts (Figure 2)〕

[0051] As a heat reflective foil, 6×10, which is easily available in the market, is obtained in a roll state -3 ~6×10 -2 For aluminum foil with a thickness in the mm range, kraft paper and aluminum foil are bonded through a conventional bonding device (not shown) consisting of a glue roller and a pressing roller to form a sheet part with aluminum foil on the surface.

[0052] Fig. 2 (A) shows the positional relationship of each constituent sheet member in the longitudinal direction of the heat shielding member before the press bonding process. As the constituent materials, the upper sheet 11, the middle sheet 13, the lower sheet 12 and the standing sheets 14 on both sides The paper with the surface covered by bonding aluminum foil, the middle stand-up sheet 15 is paper not bonded with aluminum foil, the thickness of the top sheet 11 and the two-side stand-up sheets 14 is 0.3mm, and the thickness of other sheet parts is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com