Improved multimode optical fiber and its prepn. method

A technology of multimode optical fiber and manufacturing method, applied in the field of multimode optical fiber and its manufacturing, can solve problems such as affecting the bandwidth characteristics of optical fiber, reducing optical fiber performance, affecting the application of multimode optical fiber, etc., to increase bandwidth, reduce inter-mode delay, eliminate The effect of the depression in the center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

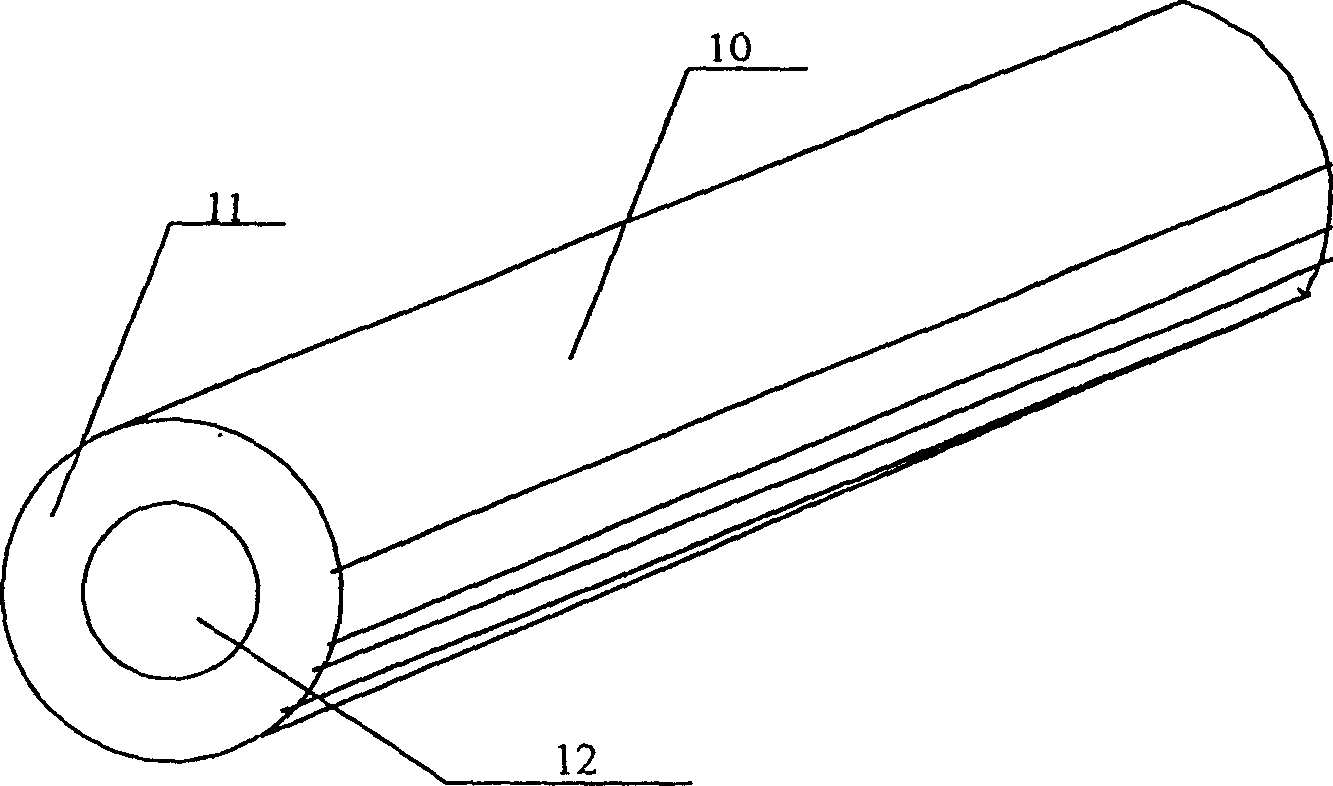

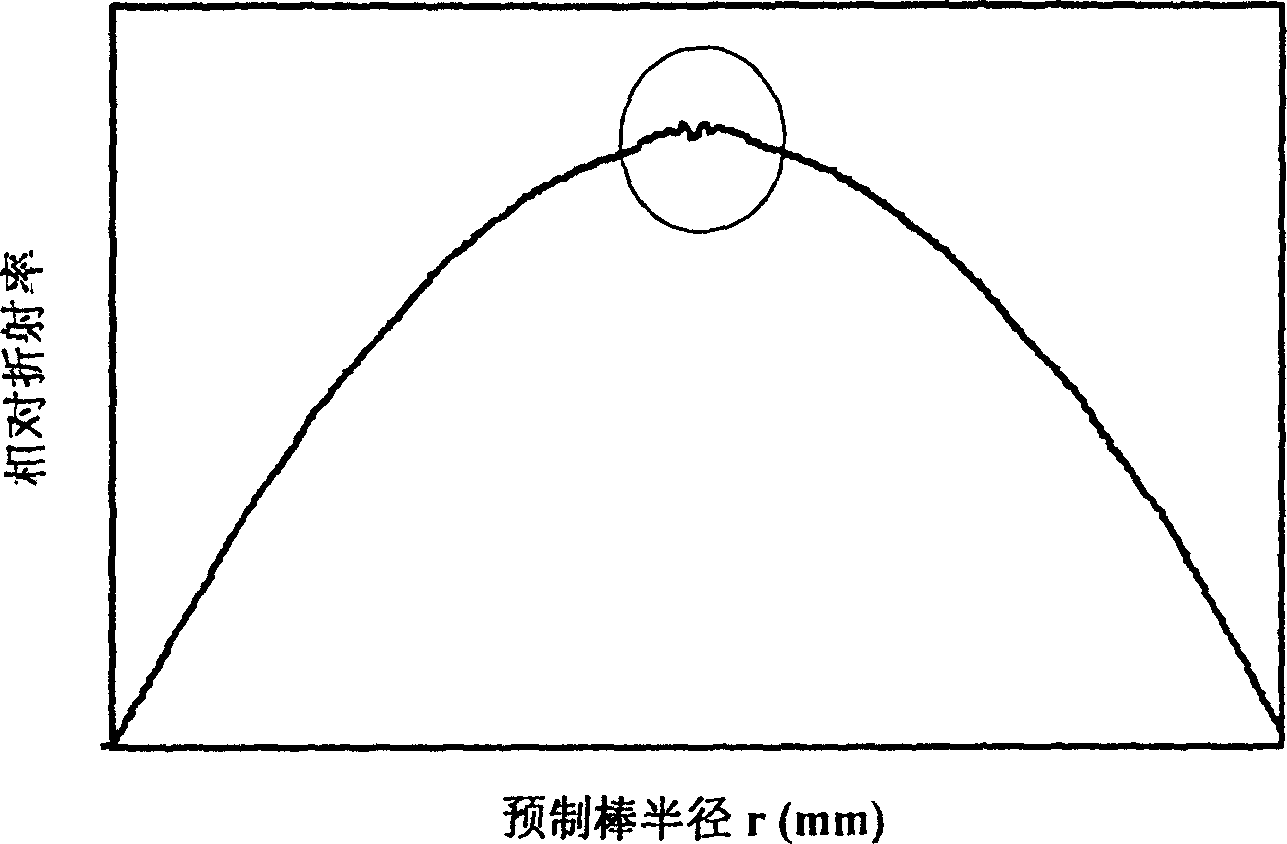

[0034] Such as figure 1 As shown, the multimode fiber 10 of the present invention includes a cladding 11 and a core 12. The diameters of the core and the cladding of the multimode fiber are 50 μm and 125 μm respectively, and its refractive index distribution is precisely optimized at a wavelength of 850 nm. The differential mode of the fiber The delay test curve is a continuous rising or falling curve, and its maximum change is less than 0.33ps / m, the full injection bandwidth is greater than 1500MHz·km at 850nm, greater than 600MHz·km at 1300nm, and the effective bandwidth is greater than 2000MHz·km and 1300nm respectively at 850nm and 1300nm 600MHz·km. The present invention adopts PCVD to deposit the cladding glass, and then deposits the core doped glass, the deposition rate is from 2.5g / min to 1.5g / min, the germanium vapor flow rate is from 3% to 60%, the number of depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com